Anti-vibrating liquid storage tank for transportation vehicle

A transport vehicle and anti-liquid technology, which is applied in the direction of transportation and packaging, containers, packaging, etc., can solve the problems of tank damage, difficulty in achieving good results, and large impact, so as to avoid liquid sloshing, reasonable design, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

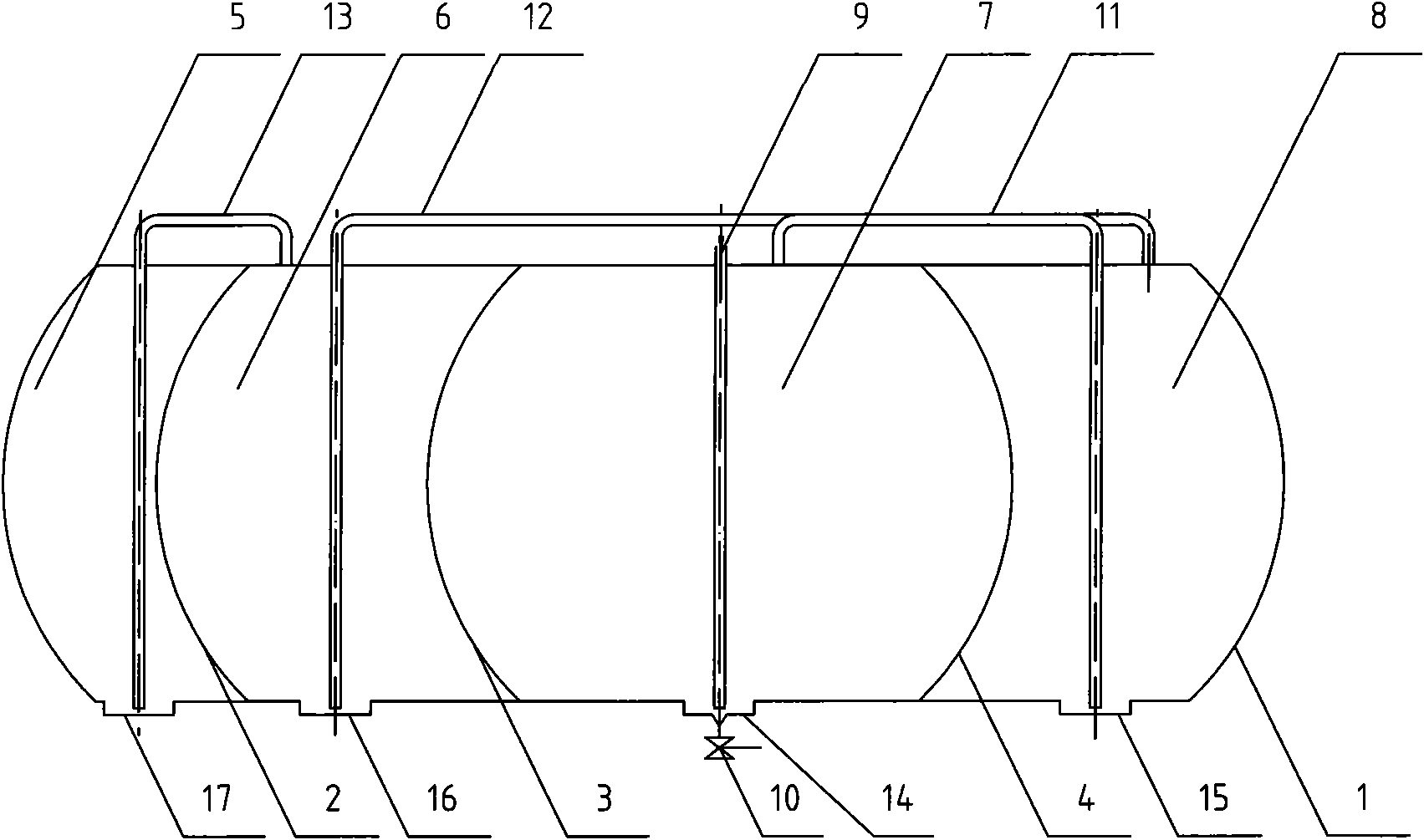

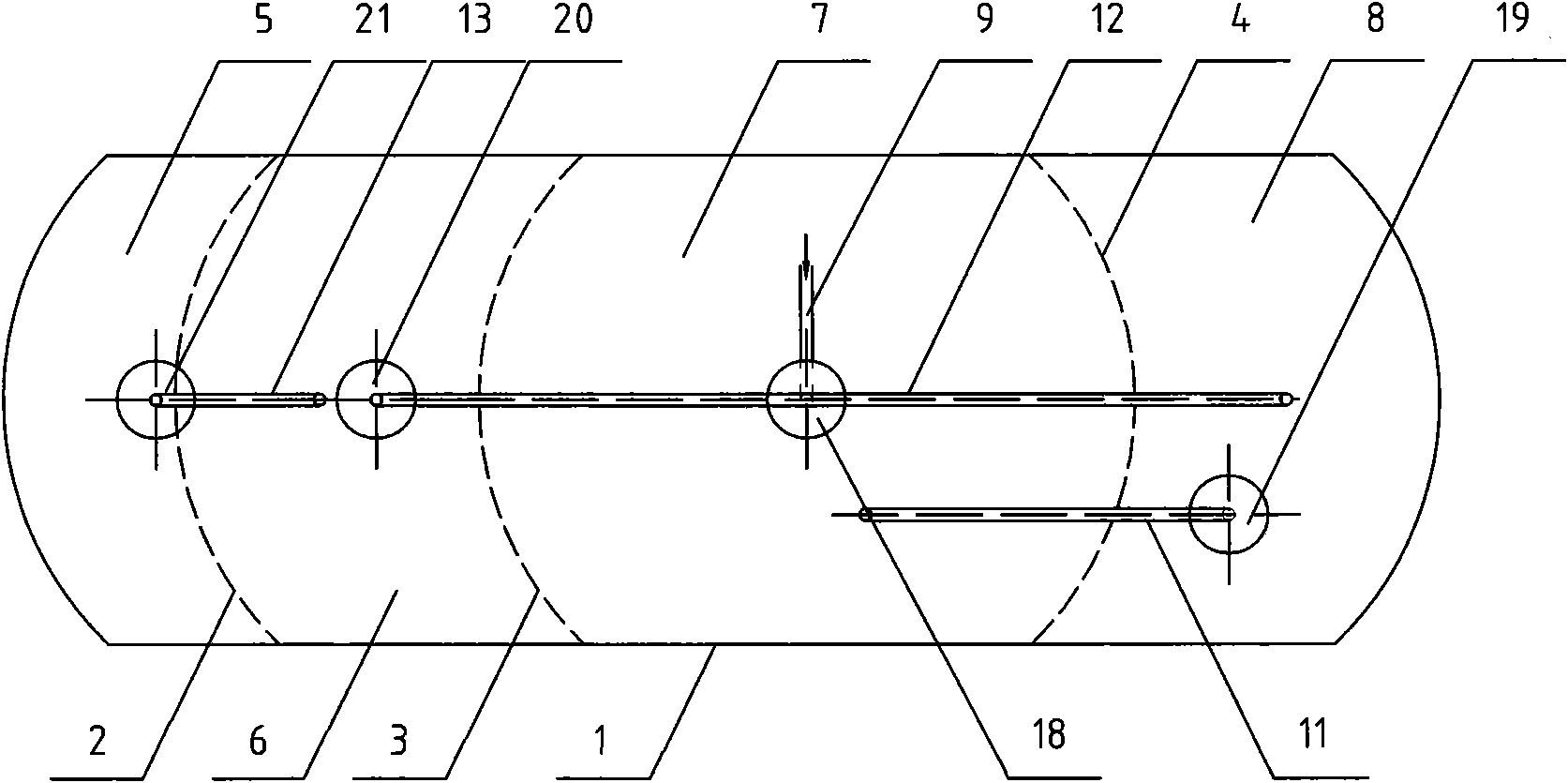

[0019] Attached below figure 1 , 2 The liquid storage tank for a transport vehicle for preventing liquid fluctuations according to the present invention will be described in detail below.

[0020] as attached figure 1 , 2 As shown, the liquid storage tank for a transport vehicle that prevents liquid fluctuations of the present invention has a structure comprising a tank body 1, the appearance of which is not much different from that of the prior art tank body, and the tank body 1 is provided with tank bulkheads 2, 3, 4, thereby dividing the inner cavity of the tank body 1 into four mutually isolated and sealed tank compartments, and the tank bulkheads 2, 3, 4 are elliptical convex structures. One of the tank compartments is used as the overflow compartment 5, and the other three tank compartments are respectively the tank compartment 6, the tank compartment 7, and the tank compartment 8. The tank compartment 7 located in the middle is provided with an injection pipe 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com