Method for separating chondroitin polysulfate from heparin sodium by extraction method

A technology of chondroitin polysulfate and sodium heparin, applied in the directions of liquid solution solvent extraction, fermentation, etc., can solve problems such as the separation technology of chondroitin polysulfate that is not reported, and achieve the effect of promoting the production of live pigs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

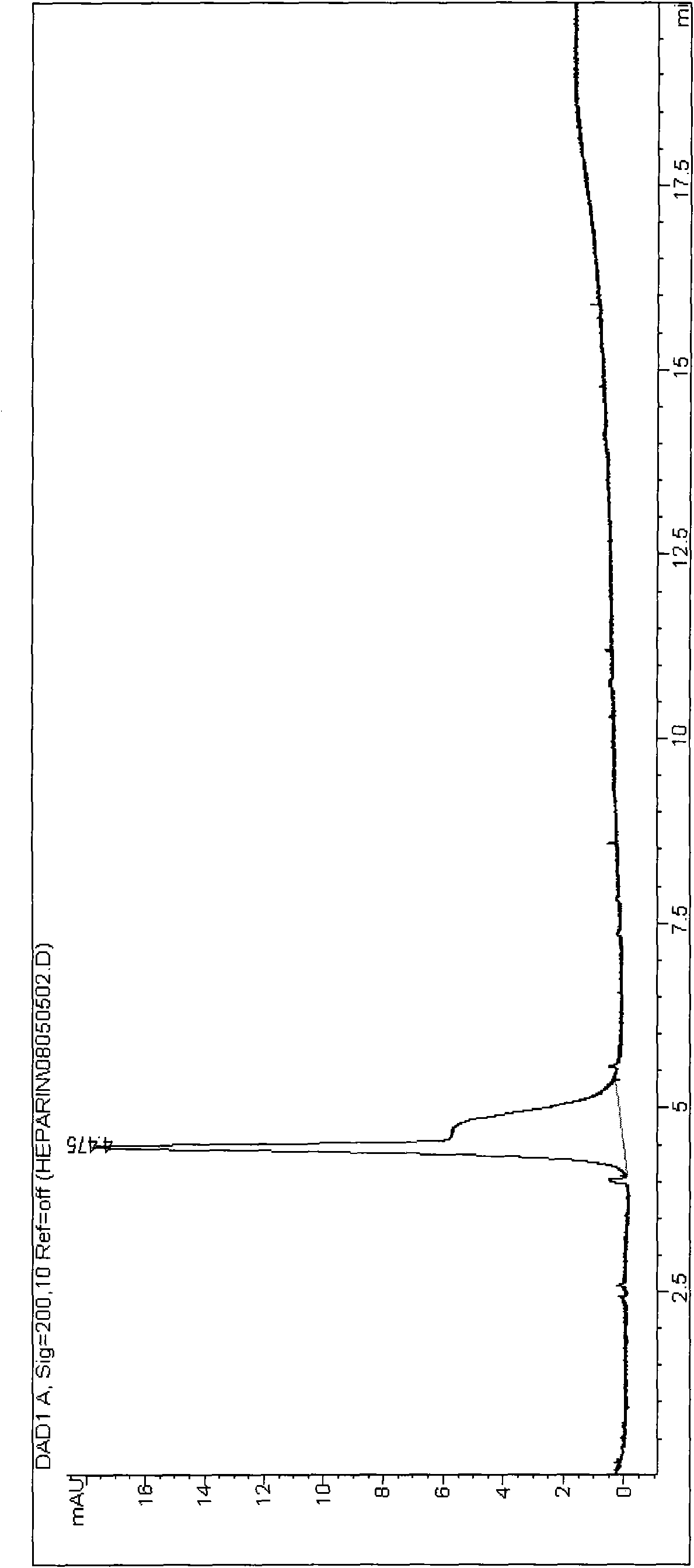

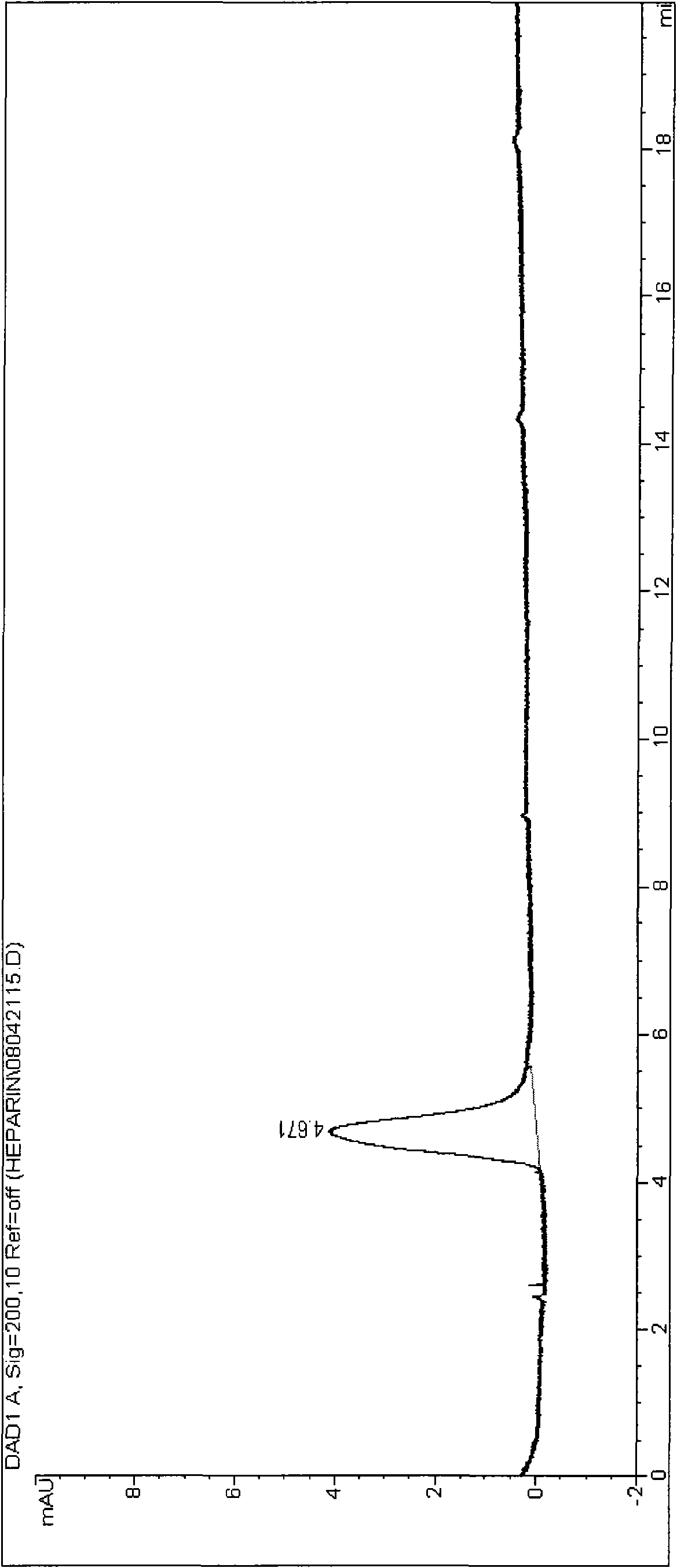

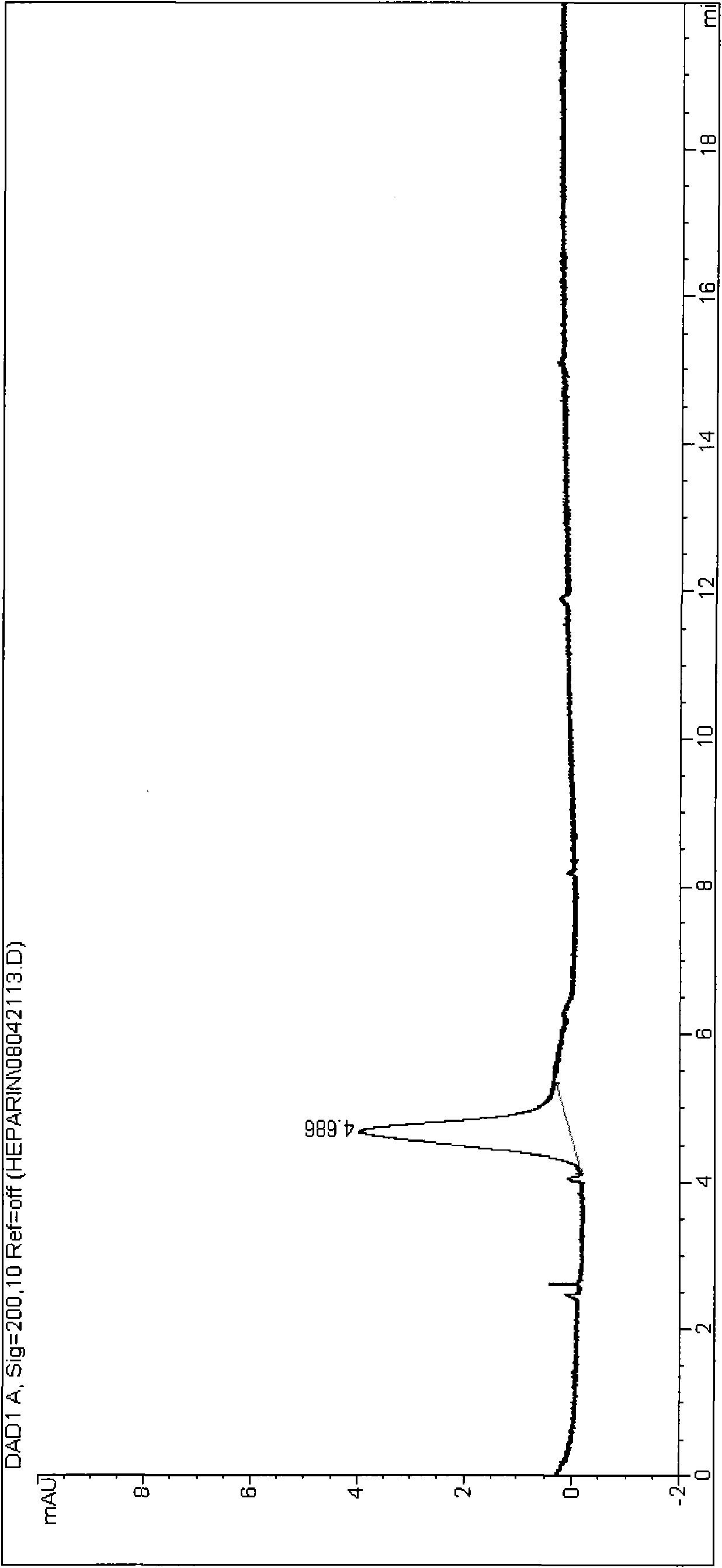

Image

Examples

Embodiment 1

[0040] 1. Extraction

[0041] 1. Crude product dissolution:

[0042] Open the water valve, add 900L of drinking water, then add 15 billion units of heparin sodium crude product into the reaction tank, add while stirring, after stirring for 6 hours, use a stirring rod to test whether the bottom is completely dissolved;

[0043] 2. Enzyme hydrolysis:

[0044] Adjust the pH of the solution in the previous step to 7.5 with hydrochloric acid solution, add 1500 g of pepsin when the temperature rises to 53 °C, then add 3000 g of trypsin, and keep warm at 53 °C for 3 hours;

[0045] 3. Rapid heating:

[0046] Heat the enzymolysis solution from the previous step to 88°C within 35 minutes, stand still for 15 minutes, start stirring, pass in circulating water to cool down, and when the temperature drops to 50°C, adjust the pH to 11.0 with 6mol / L sodium hydroxide solution, stand still Stratification for 24 hours;

[0047] 4. Centrifugation of impurities precipitated at the bottom:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com