Single-grade stone fine screening mechanism

A screening machine and stone material technology, which is applied in the direction of filtering, solid separation, grille, etc., can solve the problems that affect the quality and life of the road surface, fail to reach high-grade roads, and it is difficult to control the grading accuracy, so as to improve the quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

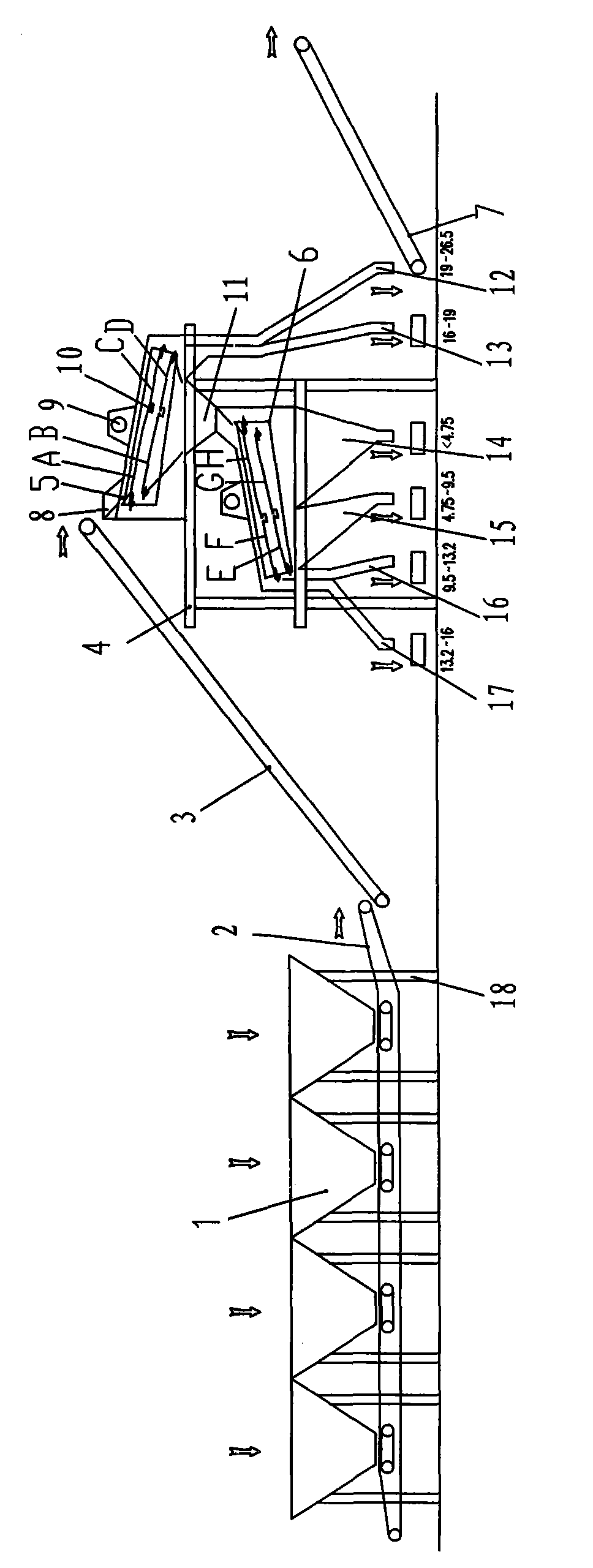

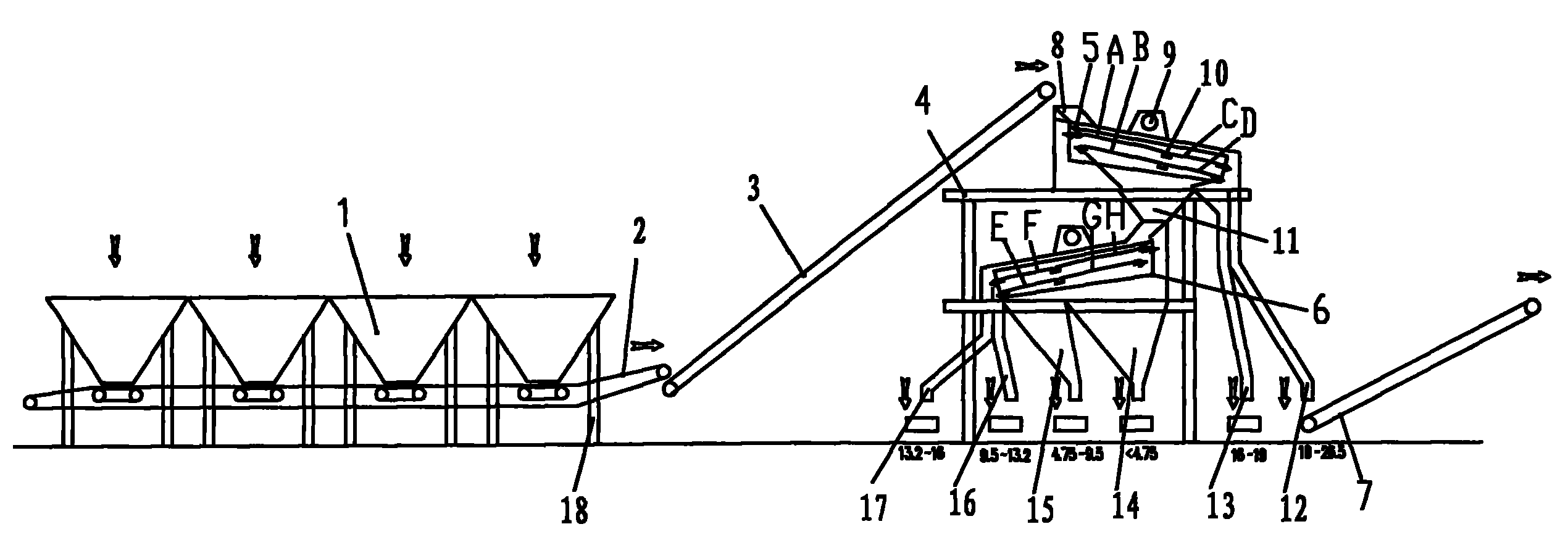

[0010] As shown in the figure: an inclined upper screening machine 5 is installed on the upper part of the frame 4, and an inclined lower screening machine 6 is installed on the frame 4 below the upper screening machine 5. The feeding port of the sub-machine 6 is connected; it is characterized in that: the upper screening machine 5 and the lower screening machine 6 all include two layers of screens; stone outlets are set at the outlet of each layer of screens; the upper screening machine 5 and the The outlet under the net of the upper screen cloth in the lower screening machine 6 is the entrance of the lower screen cloth. Each layer of screens includes two screens, and the two screens are connected to each other by fasteners 10 . According to the positions of the two screens E and G, two stone material outlets 15, 14 are respectively set under the lowermost screen cloth E, G.

[0011] When working, the stones that need to be screened first enter the feed end of the upper scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com