Fully automatic electric shock type insect killer for eliminating insects

A fully automatic insect zapper technology, applied in the direction of equipment that produces electric shocks, electrical components, devices that capture or kill insects, etc., can solve the problems that insects cannot be shocked by electric shocks, damaged, and easy to stick to insects, etc. Achieve good power-saving effect, excellent power-saving effect, and good insect harvesting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the present invention in the next step with reference to the drawings and embodiments:

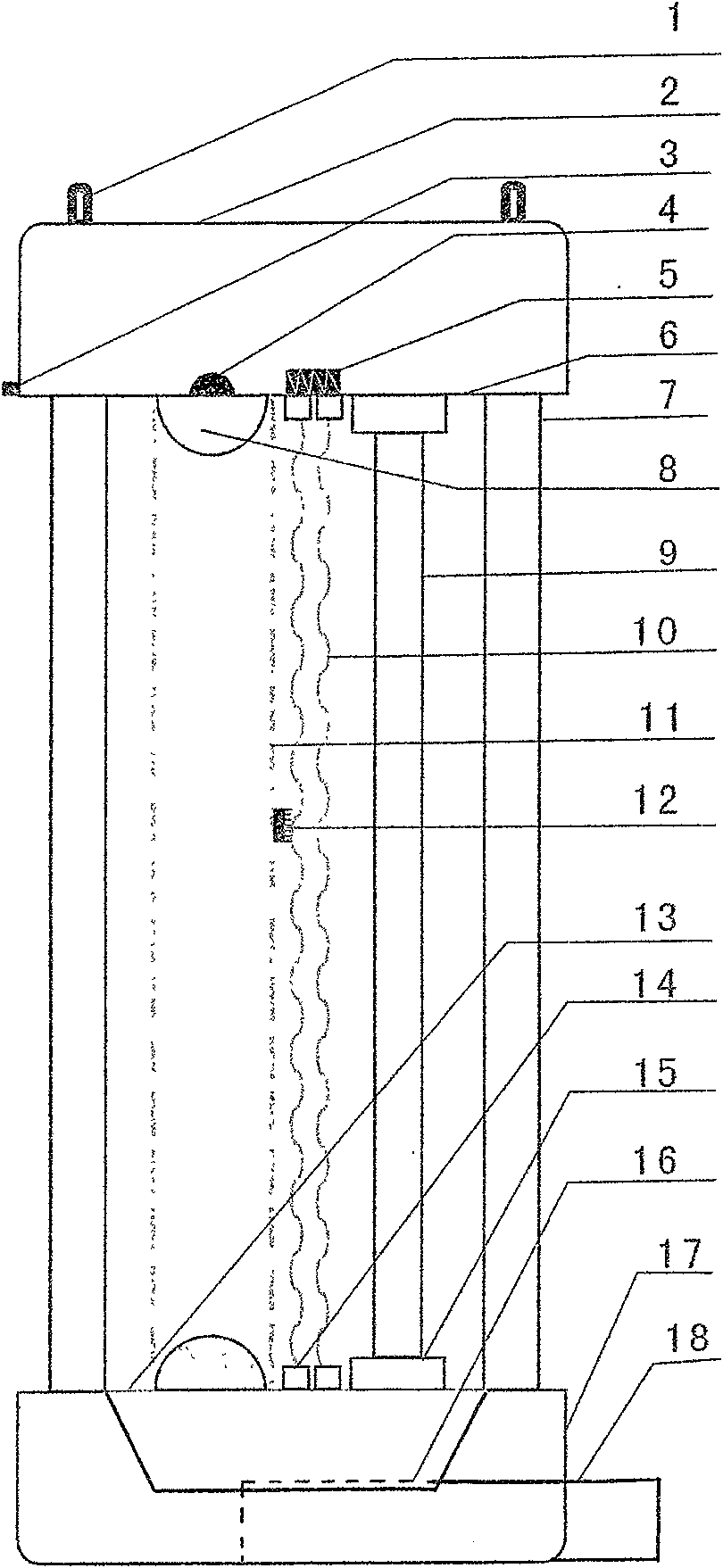

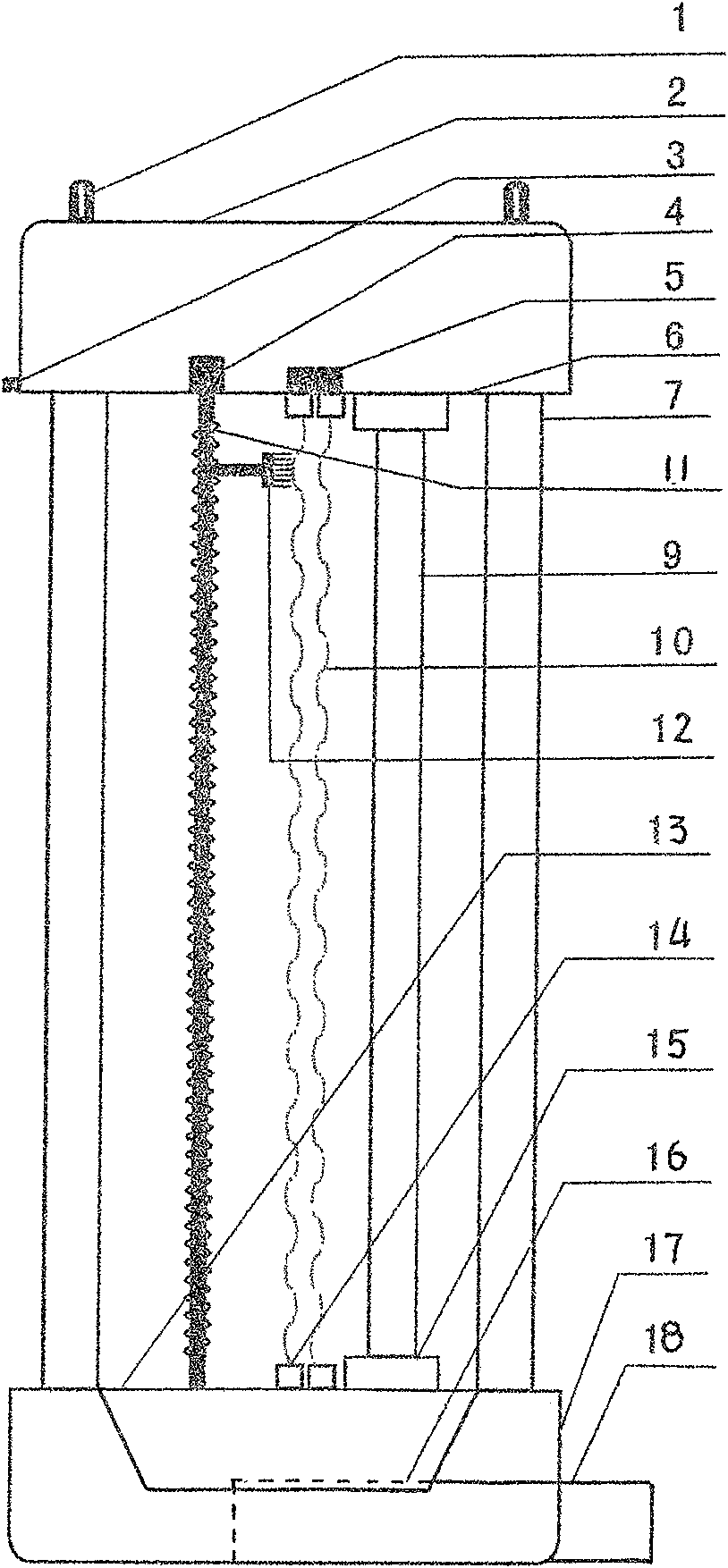

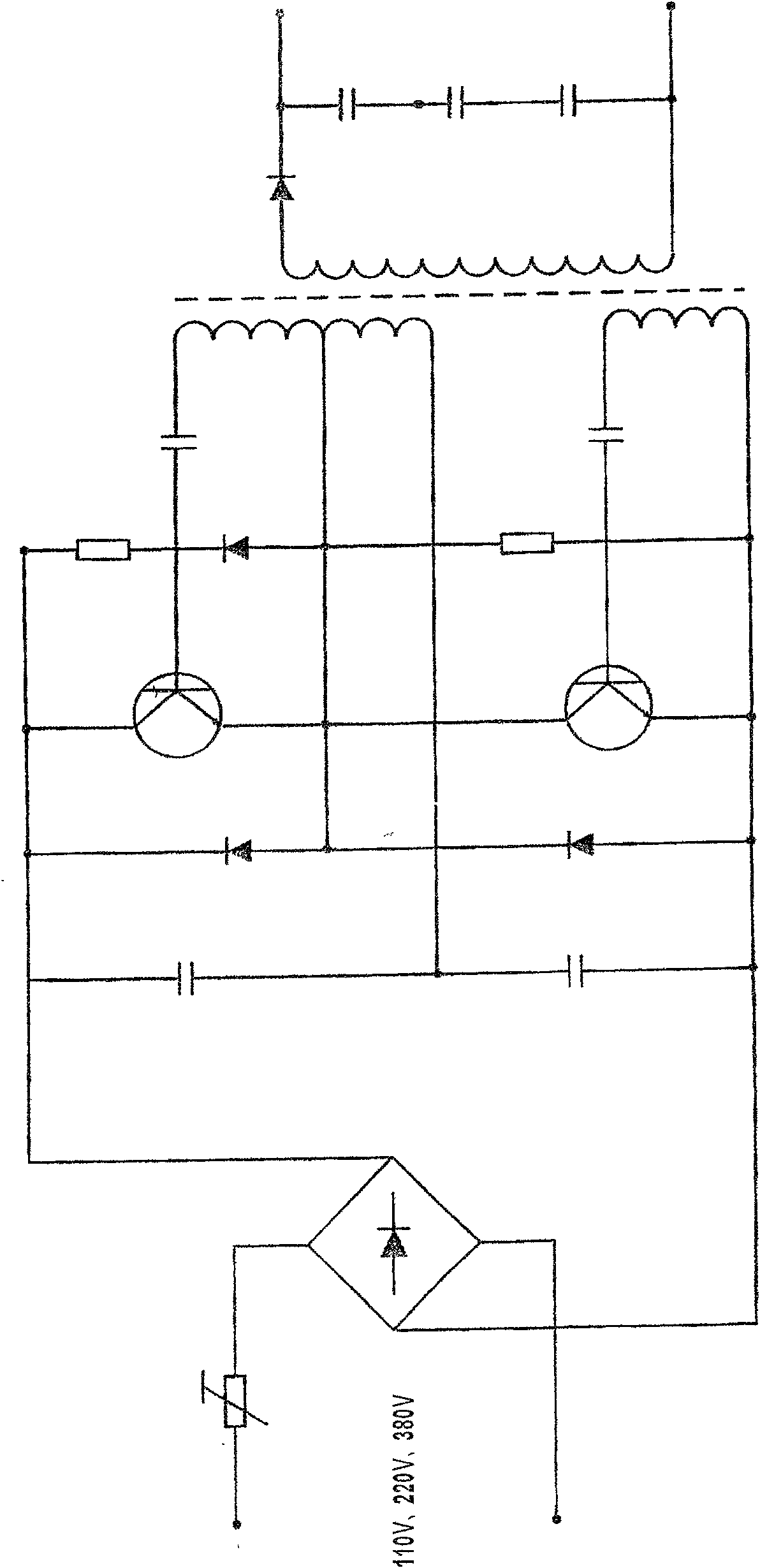

[0019] A full-automatic insect-removing electric-shock type insect exterminator, such as figure 1 As shown, it is mainly composed of the upper cover 2, the body support 7, the insect cleaner 4, 11, 12, the insect trap tube 9, the high voltage power grid 10, the control circuit 5 and the insect receiving box 18. Among them: the insect killer consists of the upper The cover 2, the support plate 6, the insect receiving funnel plate 17, the body support 7 and the high-voltage power grid 10, the insect cleaner 4, 11, 12 are composed of the motor 4, the transmission chain 11 or the belt 11 and the brush 12, and the insect trap lamp The tube 9 is composed of an inert gas lamp tube or LED light-emitting diode, a reflective material, a glass tube and a tube base 15. The high-voltage power grid 10 is composed of metal wires, which are arranged upright or horizontally fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com