Multi-axial chain device for warp knitting machine

A warp knitting machine and multi-axial technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as waste products, affecting the quality of cloth surface, etc., achieve easy disassembly, simple structure, and the ability to increase tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with the embodiment given with accompanying drawing.

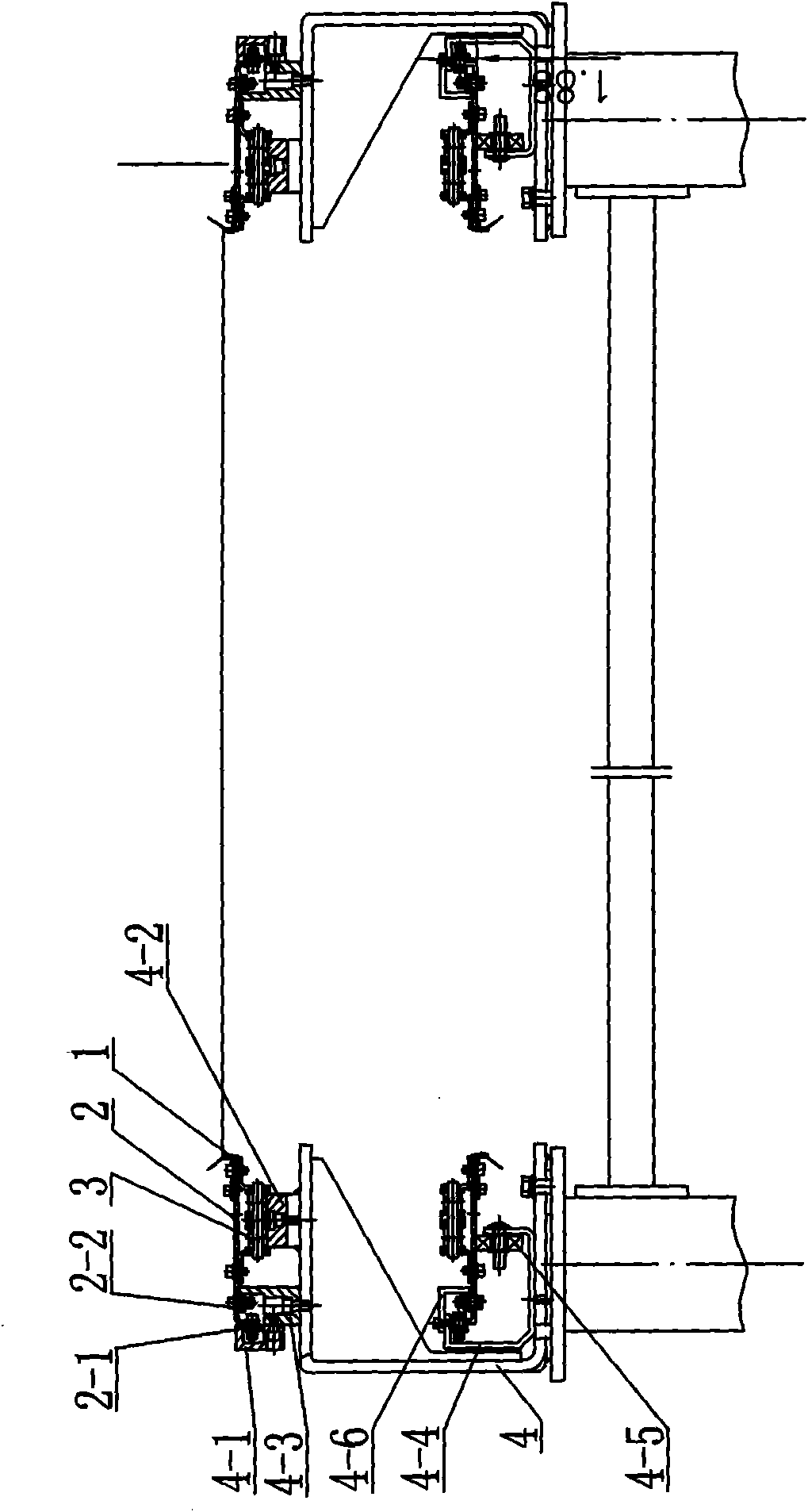

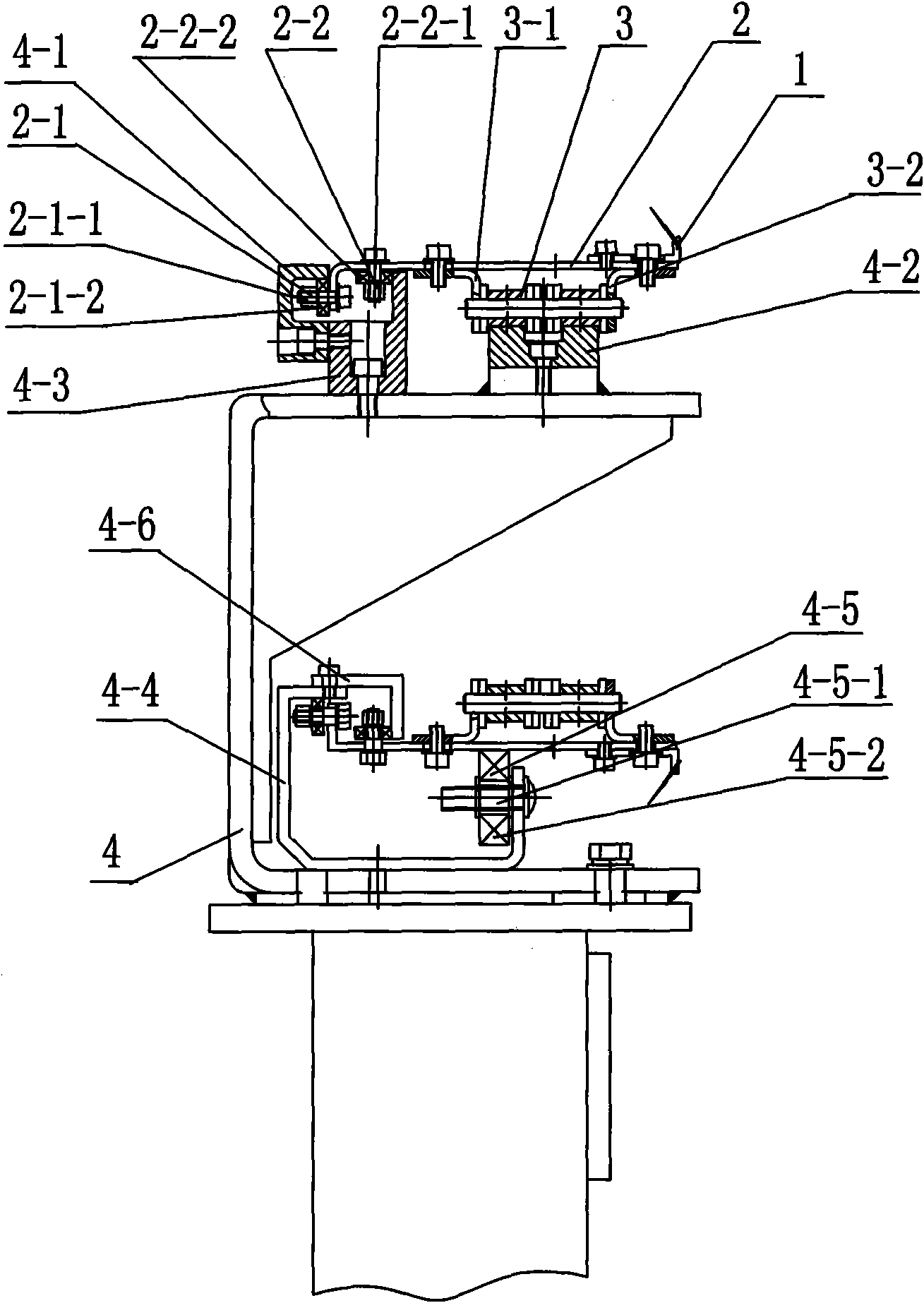

[0020] see figure 1 , 2 , a chain device for a multiaxial warp knitting machine, comprising a needle plate 2 equipped with a needle block 1, at least one chain link 3 and a horizontal U-shaped chain box 4, the chain link 3 has left, Right side plate 3-1, 3-2, the top on the horizontal U-shaped chain box dresses and connects limit block 4-1 and slide rail 4-2, and chain link 3 dresses and is connected on the top of slide rail 4-2, and its The innovation points are:

[0021] a. One end of the needle plate 2 is connected with a needle block 1, and the other end has a 90° bend. The vertical surface of the bend is provided with a first roller 2-1 with a horizontal axis, and the first roller 2- 1 is fitted in rolling fit with the limit block 4-1 on the top of the horizontal U-shaped chain box 4;

[0022] b. The second roller 4-2 of the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com