Method for testing opening and closing pressure of gum cap of safety valve of lead-acid accumulator and special testing device thereof

A technology of lead-acid battery and detection device, which is applied in the direction of pressure difference measurement between multiple valves, measurement device, and measurement of fluid pressure. It can solve the problems of detection data influence, deviating from the working state of safety valve, etc., and achieve convenient detection and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

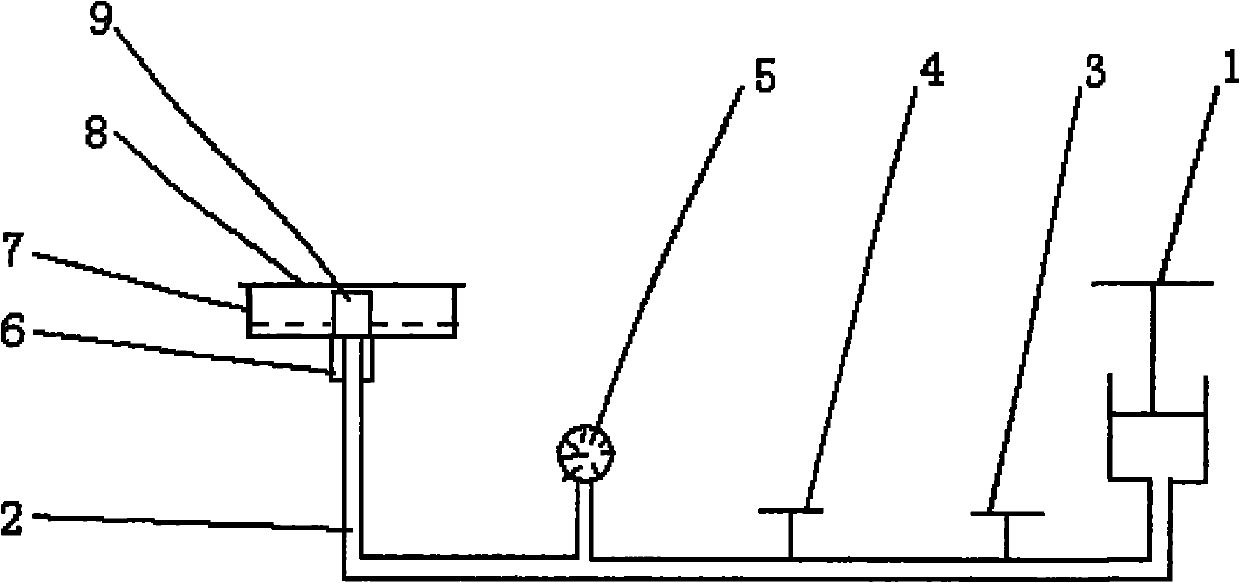

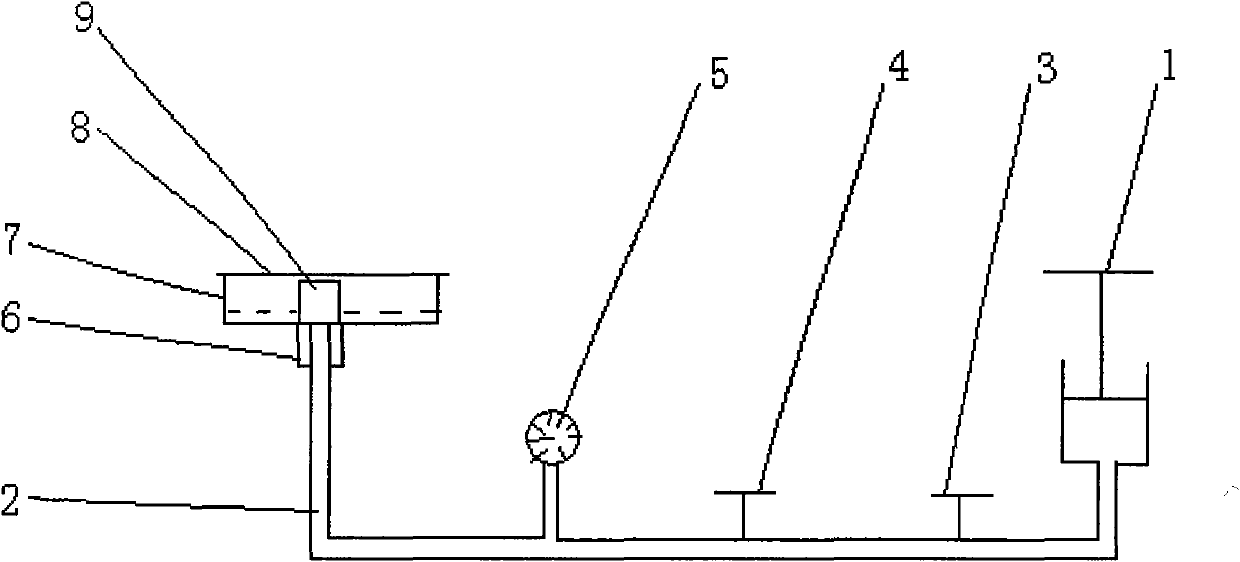

[0017] The detection method for the opening and closing pressure of the rubber cap of the lead-acid battery safety valve includes the following steps:

[0018] (1) Test at an environment of 25±5°C, connect the safety valve to the liquid injection hole of the battery middle cover of the analog detection head of the special detection device and compact it, and drop an appropriate amount of water into the groove around the liquid injection hole Water, it is advisable not to pass through the lower edge of the safety valve 9 rubber cap, and then cover the transparent cover of the analog detection head on the battery cover; then insert one end of the plastic tube into the liquid injection below the battery cover holes to ensure no air leakage;

[0019] (2) Close the pressure relief valve on the plastic pipe in the special detection device, open the stop valve, apply pressure to the pressure valve, pay attention to the movement of the rubber cap of the safety valve 9, and it can be c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com