Fuel-economizing maintenance tool of carburetor

A maintenance tool and carburetor technology, which is applied in the field of carburetor fuel-saving maintenance tools, can solve the problems of high fuel consumption, pollution, and uneven manufacturing process precision, and achieve the effect of improving atomization combustion performance and fuel-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

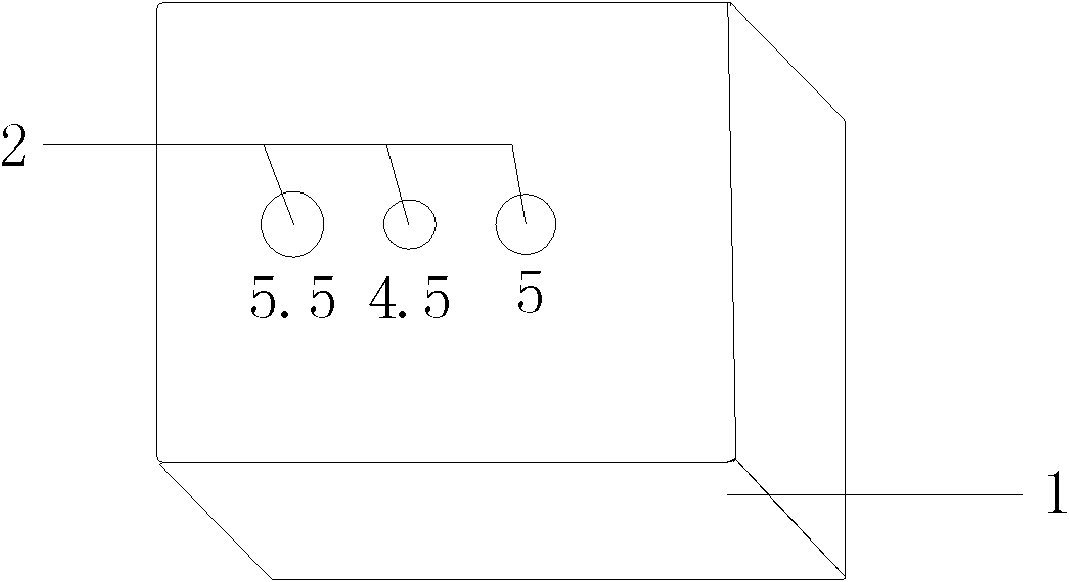

[0014] exist figure 1 Among them, the height of the pad iron (1) is higher than 10mm, and the length and width are larger than 5mm. There is a 5mm through hole (2) and a 4mm through hole (2) and a 5.5mm through hole (2) in the middle of the pad iron (1). through hole (2).

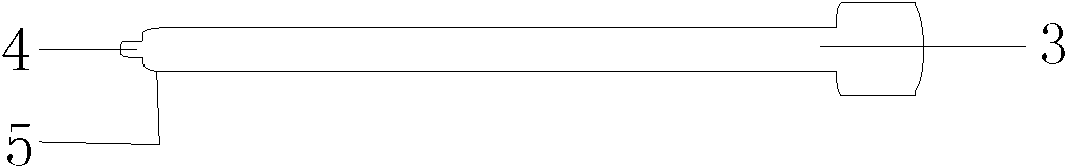

[0015] exist figure 2 Among them, the length of the main nozzle shrinkage rod (3) is 70mm, and there is a positioning pin (4) on it, mainly to prevent the shrinkage rod from running sideways. The diameter is 4mm, and the positioning pin (4) is 1.5mm in diameter.

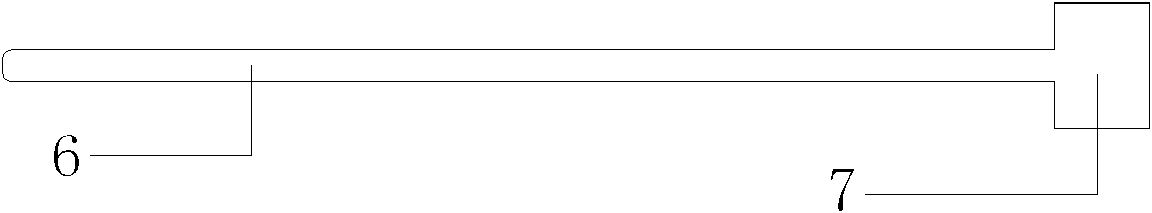

[0016] In figure 3, transition nozzle shrinkage rod (6) total length 100mm, rod diameter 2mm, rod end (7) 3mm, rod head has R angle, R angle 1 °.

[0017] exist Figure 4 Among them, the total length of the main nozzle reamer (8) is 40mm, the diameter of the reamer is 2.5mm, and the top of the reamer becomes a sharp angle.

[0018] exist Figure 5 Among them, transition nozzle reamer (9) total length 100mm, reamer blade (10) length 2mm diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com