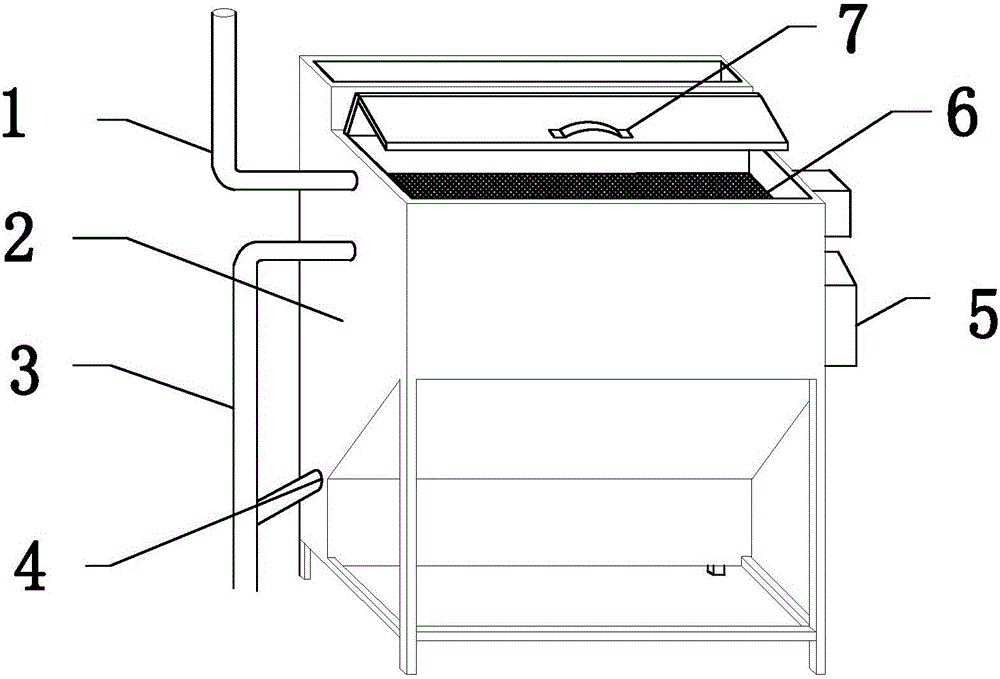

Energy-saving rice bran crude oil filter equipment

A technology of rice bran crude oil and filtration equipment, which is applied in the direction of filtration circuit, filtration separation, fat oil/fat refining, etc. It can solve the problems of easy blockage of the filter screen by filter residue, lower product yield, and affect production efficiency, so as to avoid industrial accidents, The effect of reducing procurement costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

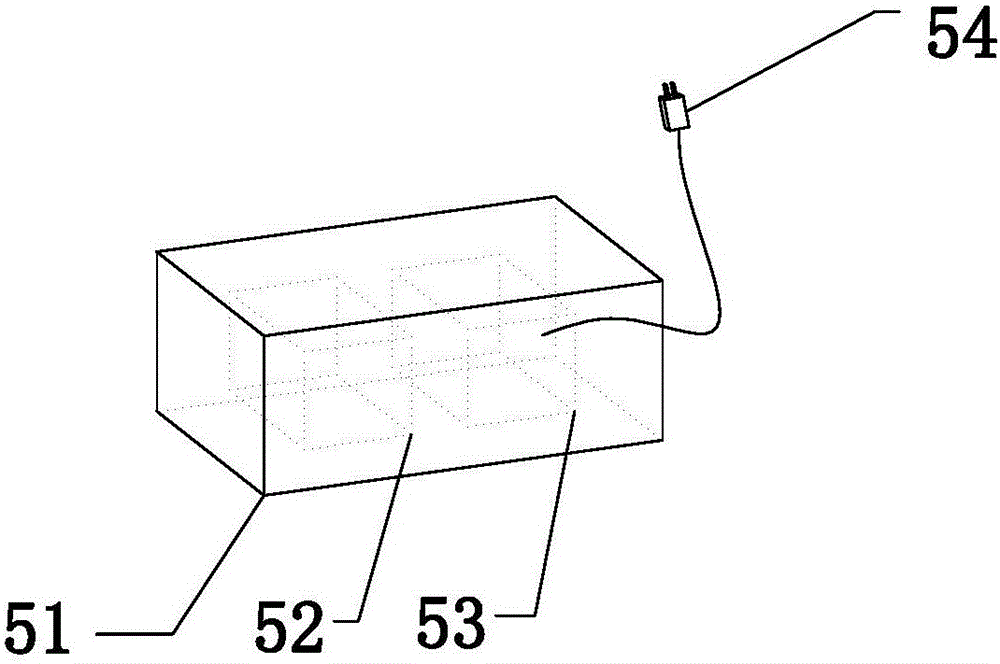

[0026] Specific implementation method: the operator inserts the plug 54 into the socket, the plug 54 transmits the electric energy to the charger 53 in the housing 51 through the power cord, and the charger 53 transmits the electric energy to the storage battery 52, thereby charging the storage battery 52, and the storage battery 52 is fully charged. After electrification, pull out plug 54, because the present invention has added storage battery, 52, charger 53 and plug 54, this design has solved the drawback that original crude oil filter energy consumption is high, has saved electric energy, has reduced energy consumption, and is the enterprise Reduced production costs.

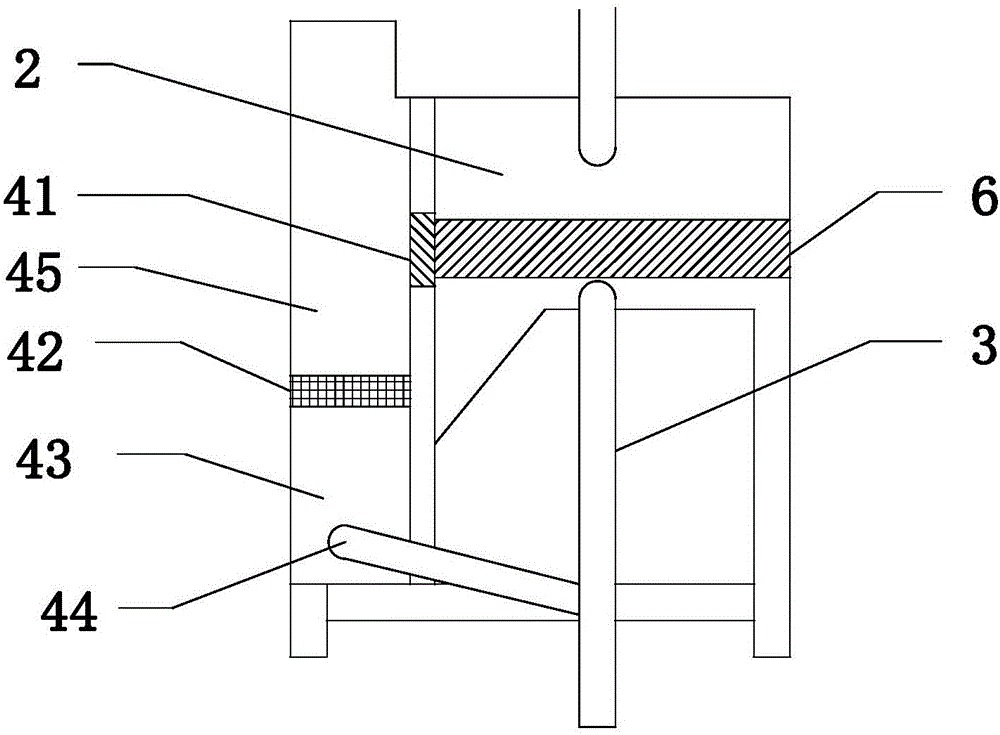

[0027] When the crude oil is transported into the body 2 through the oil inlet pipe 1, the crude oil passes through the oil filter 62, and the oil residue in the crude oil is absorbed by the oil filter 62, and the operator runs the motor 64, which drives the drive shaft through the connecting shaft 65 61 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com