Railroad freight car sidebearing

A side support and carriage technology, which is used in transportation and packaging, devices for lateral relative movement between the underframe and the bogie, railway car body components, etc., and can solve the problems of restricting the vertical movement of the side support device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

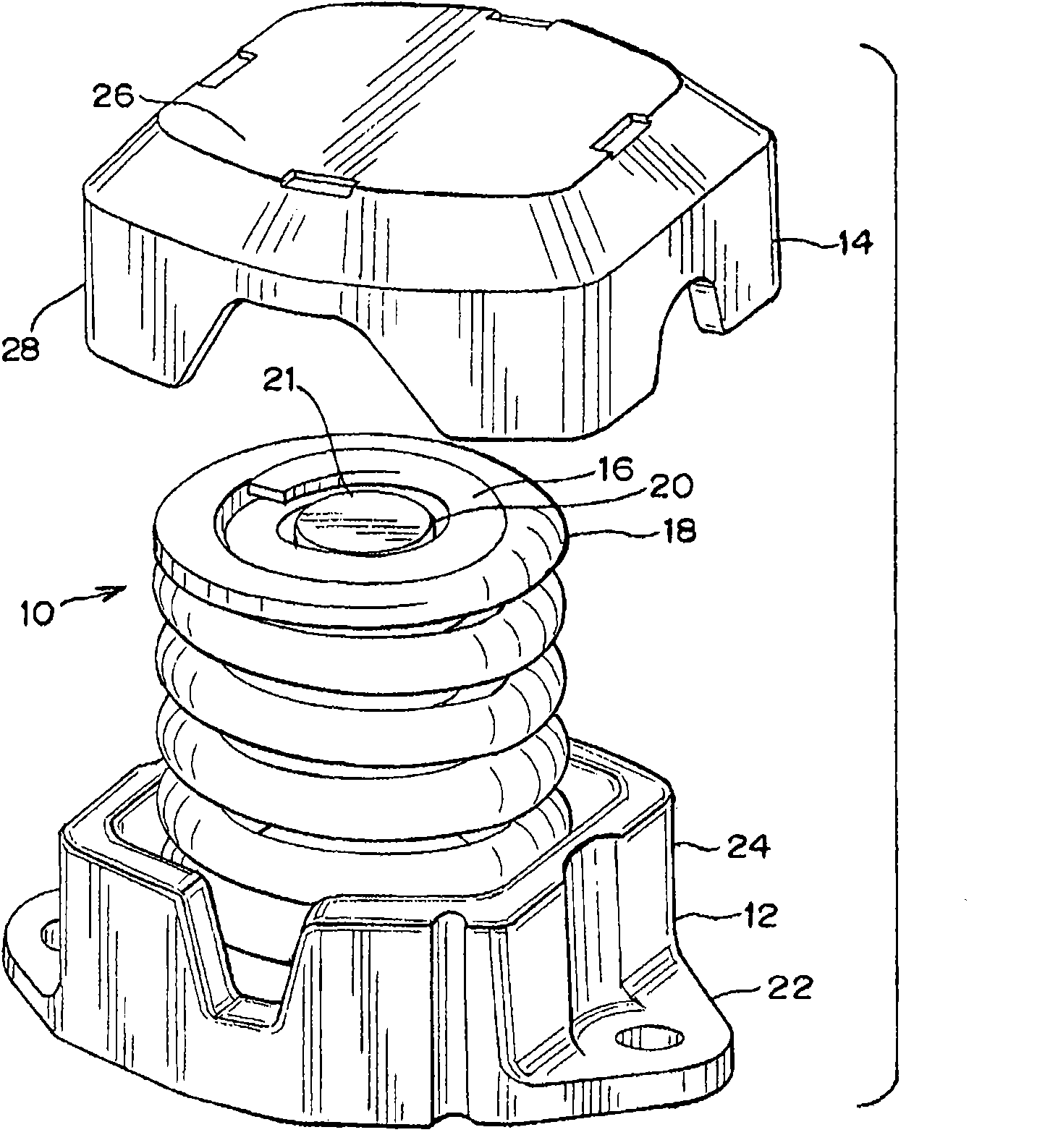

[0027] now refer to image 3 and Figure 4 , shows the side support device according to the first embodiment of the present invention. The side support 10 includes a base 12 including a base 22 and a base wall 24 extending generally vertically upward from the base 22 . Base 12 is typically a cast steel or cast iron unitary construction, but may also be fabricated or machined. The shape of the base 12 may be a user-specified circle, somewhat rectangular, somewhat oval, or rhombus.

[0028] The lid 14 is seen to include a top 26 and a wall structure 28 extending generally downwardly from the outer edge of the lid 14 . Again, cover 14 is typically of cast steel or cast iron unitary construction, but may be fabricated or machined.

[0029] The base 12 is seen to also include a base wall top stop surface 38 at the top of the base wall 24 . Likewise, the lid 14 is seen to include an inner lid stop surface 30 formed by an inner surface within the lid 14 and adjacent to and compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com