Protective device for anti-wear route development

A protective device and anti-wear technology, applied in the direction of overhead lines, etc., can solve the problems of cumbersome use and non-portability, and achieve the effects of reducing labor and labor intensity, construction safety, and labor-saving line development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

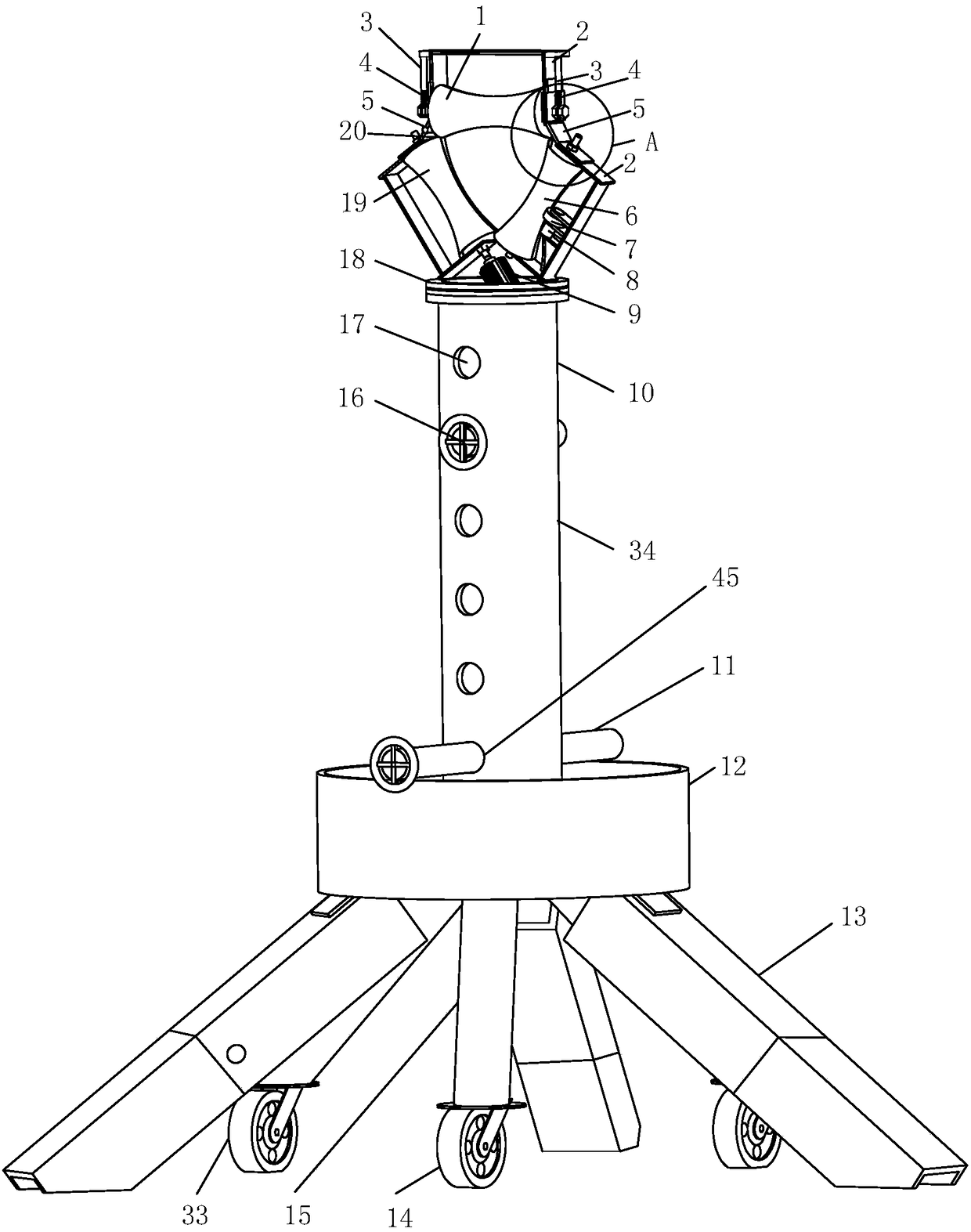

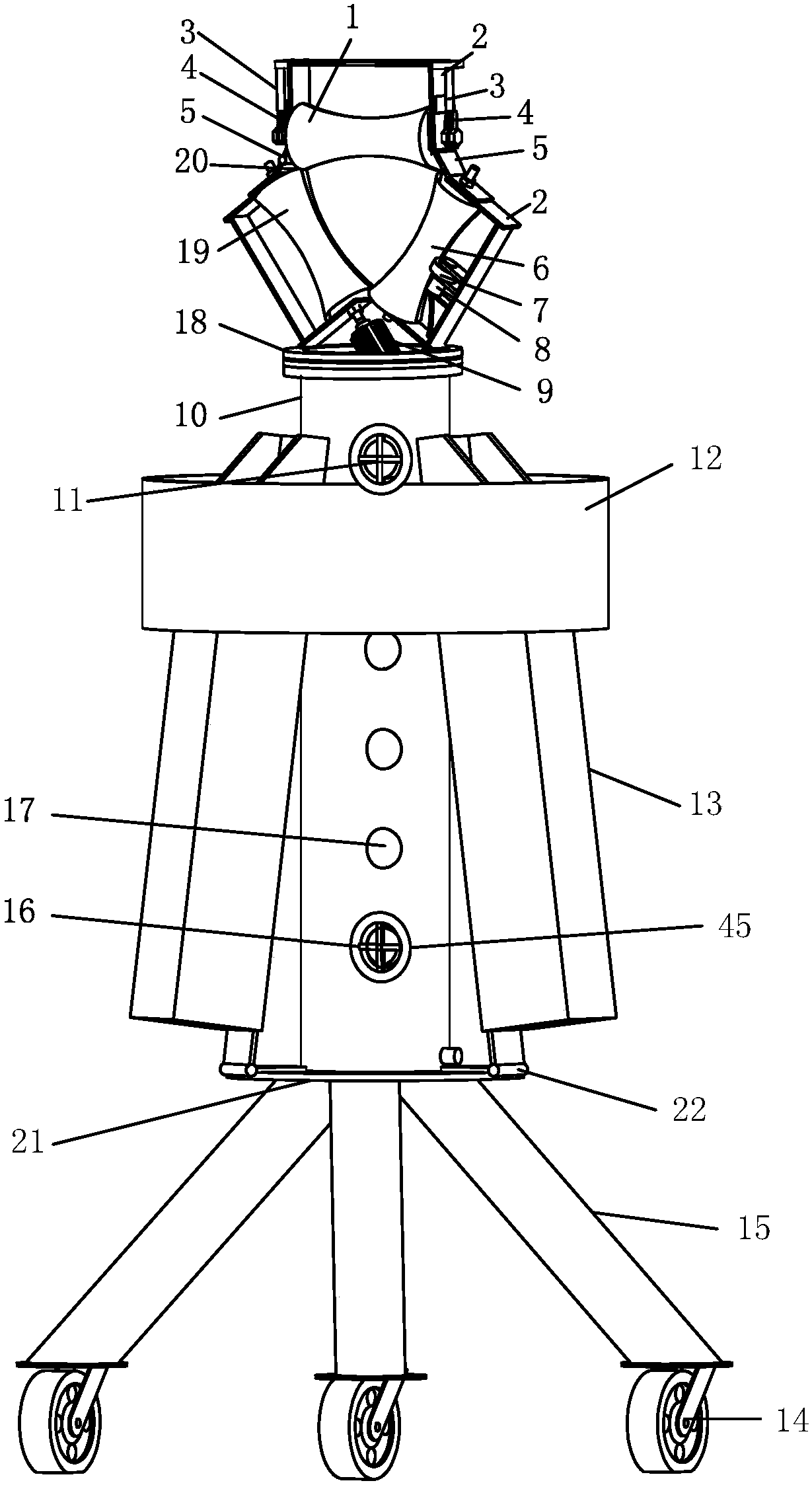

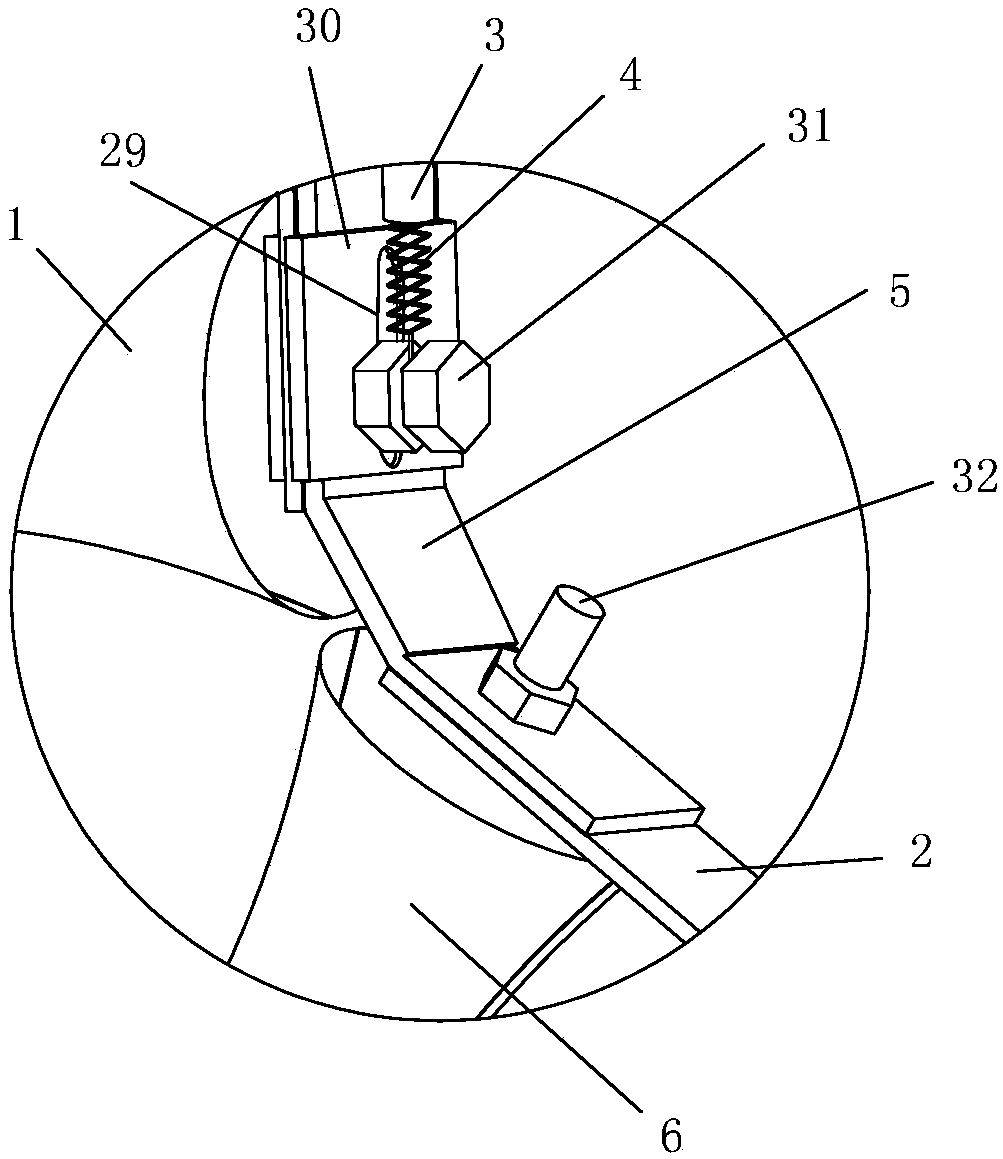

[0031] Below in conjunction with accompanying drawing and preferred embodiment the present invention is further described: as figure 1 , 2 The anti-wear and stretching protection device shown in , is provided with a combination of a stretching retainer 20, a height adjustment bracket 10 and a walking frame 33 from top to bottom, wherein the stretching retainer 20 is assembled by a runner The inside of the vertical plane is ring-shaped, and the runner set is provided with at least three runners. The present invention is described by taking three runners as an embodiment. The gap between adjacent runners is less than 1 / 3 of the diameter of the cable passed through. In actual application, the cable passes through the wire spreading retainer 20 for cable deployment. Since the runner group forms a closed ring, The stretched cable passing through the stretching retainer cannot come out.

[0032] The height-adjusting support 10 includes a vertically arranged outer support pipe 34 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com