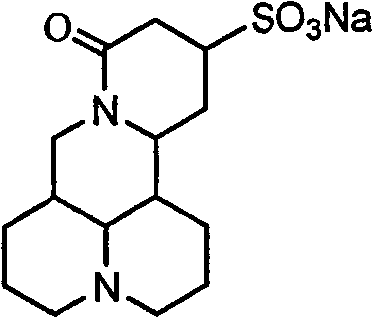

Matrine sodium sulfonate and preparation method

A technology of sodium matrine sulfonate and sulfonating agent, which is applied in the field of sodium matrine sulfonate and its preparation, can solve the problems of central nervous system toxicity and side effects, poor water solubility, inhibition, etc., and achieve increased water solubility, low cost, The effect of reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

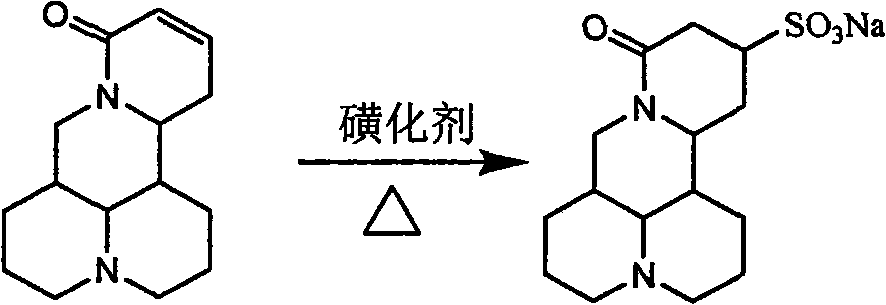

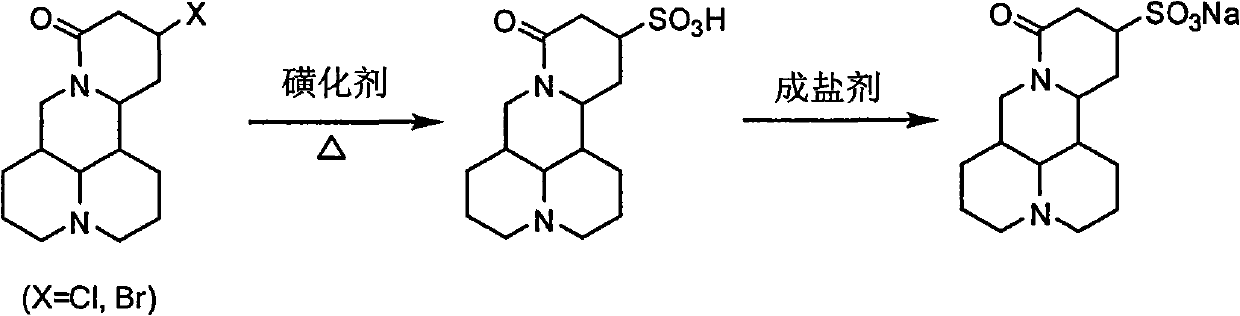

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the preparation of sodium matrine sulfonate

[0023] Weigh 10g of sophocarpine, add 70mL of water to dissolve it, heat up to 80°C, slowly add the sulfonating agent sodium bisulfite under stirring condition according to the molar ratio of sophocarpine and sulfonating agent of 1:1, and control the temperature at 80°C Under reduced pressure and reflux reaction, the reaction process was monitored by thin layer chromatography (TLC). After 12 hours, the reaction was completed, and the unreacted sophocarpine was extracted with chloroform, the chloroform extract was discarded, the water layer was collected, filtered, and the filtrate was concentrated under reduced pressure. To dryness, the residue was recrystallized with ethanol and dried to obtain sodium matrine sulfonate with a yield of 85.6%.

Embodiment 2

[0024] Embodiment 2, the preparation of sodium matrine sulfonate

[0025] Weigh 10g of sophocarpine, add 70mL of water to dissolve it, heat up to 60°C, slowly add the sulfonating agent sodium bisulfite under stirring condition according to the molar ratio of sophocarpine to sulfonating agent of 1:2, and control the temperature at 60°C Under reduced pressure and reflux reaction, the reaction progress was monitored by TLC method. After 12 hours, the reaction was completed. The unreacted sophocarpine was extracted with chloroform, the chloroform extract was discarded, the water layer was collected, filtered, the filtrate was concentrated to dryness under reduced pressure, and the residue Recrystallize with a mixed solvent of ethanol and ethyl acetate, and dry to obtain sodium matrine sulfonate with a yield of 84%.

Embodiment 3

[0026] Embodiment 3, the preparation of sodium matrine sulfonate

[0027] Weigh 10g of sophocarpine, add 70mL of water to dissolve it, heat up to 40°C, slowly add the sulfonating agent sodium bisulfite under stirring condition according to the molar ratio of sophocarpine to sulfonating agent of 1:3, and control the temperature at 40°C Under reduced pressure and reflux reaction, the reaction process was monitored by TLC. After 12 hours, the reaction was completed, and the unreacted sophocarpine was extracted with ethyl acetate, the ethyl acetate extract was discarded, the water layer was collected, filtered, and the filtrate was concentrated under reduced pressure to After drying, the residue was recrystallized with a mixed solvent of ethanol and acetone, and dried to obtain sodium matrine sulfonate with a yield of 84.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com