Self-powered air relief device

An unloading device and gas technology, which is applied in the direction of machines/engines, liquid variable displacement machinery, pump control, etc., can solve the problems of medium leakage, inability to ensure full sealing, and large butterfly valve torque, so as to prevent tearing and improve the scope of application , the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

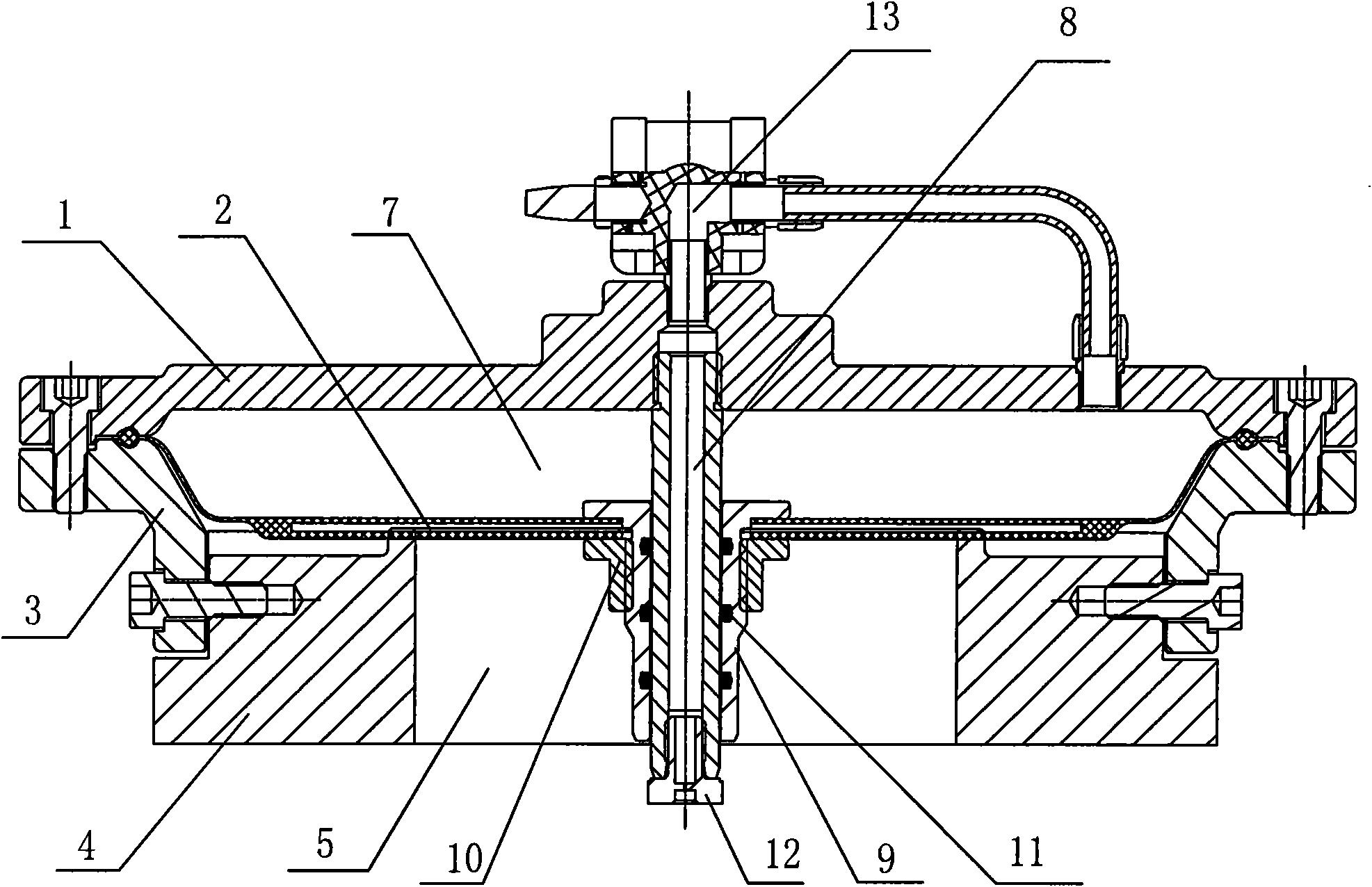

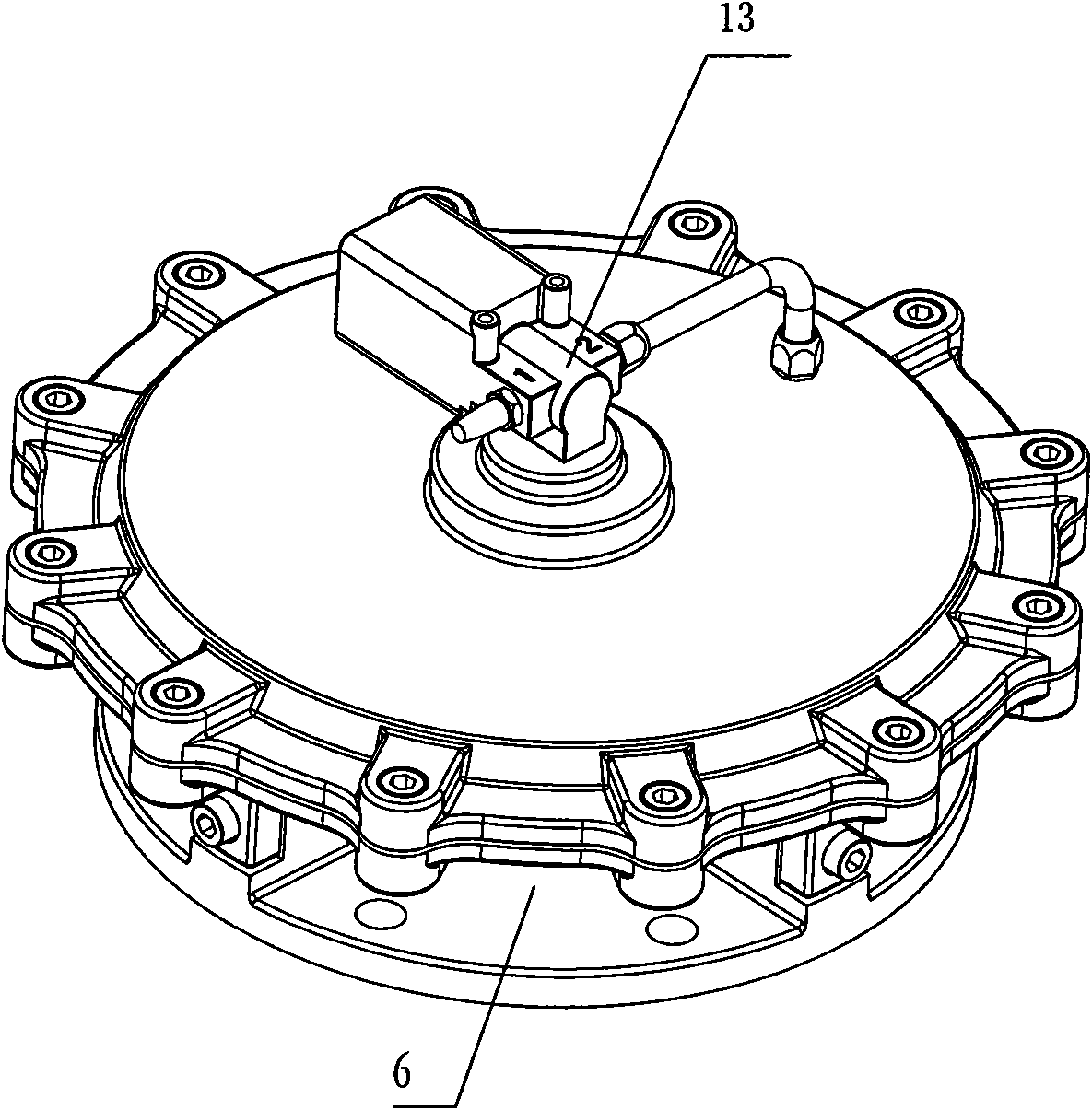

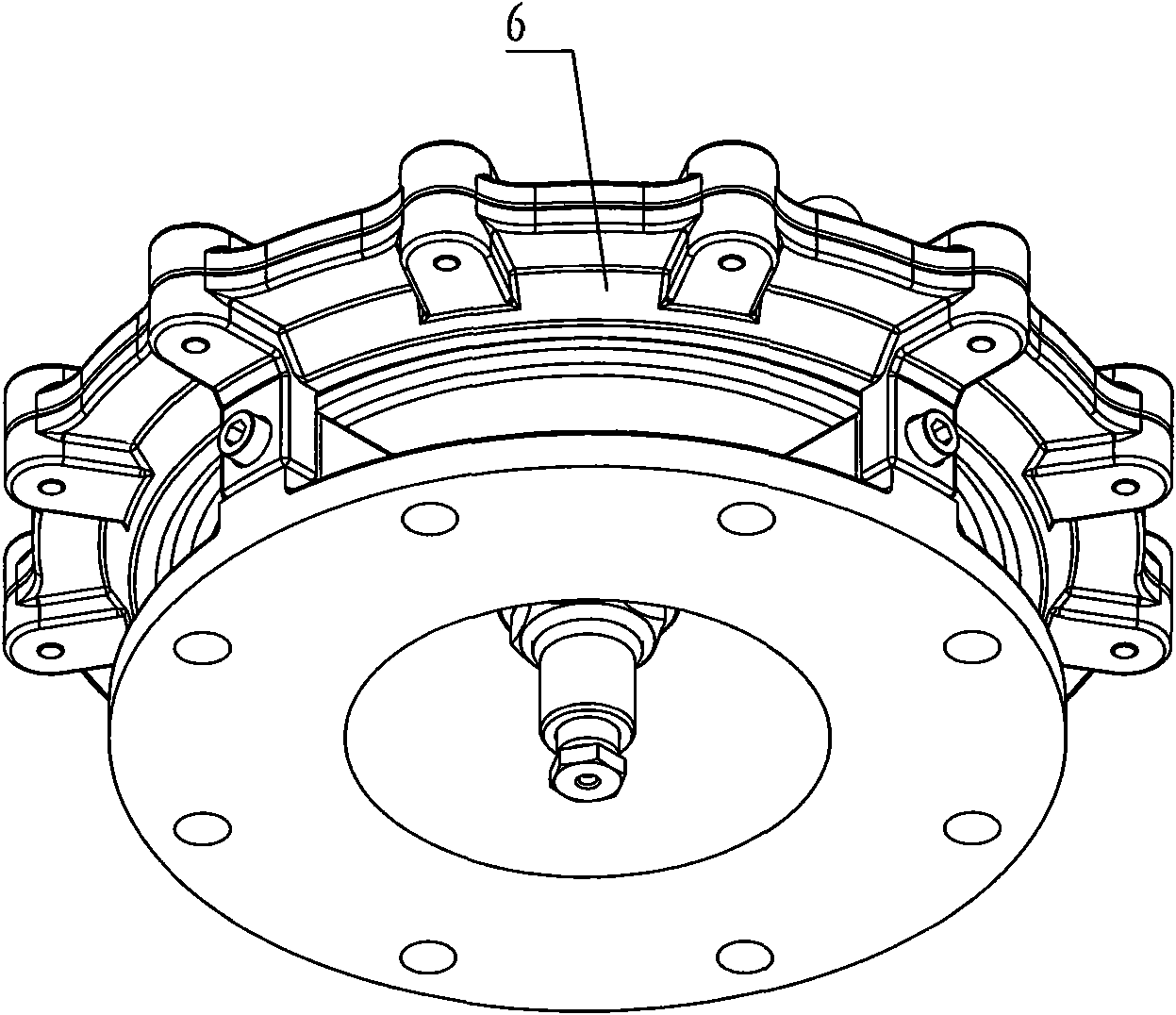

[0024] refer to figure 1 , figure 2 , image 3 , for adopting a kind of automatic power gas unloading device of the present invention, suitable for Roots blower air supply system and multi-pole centrifugal blower air supply system. Among them, the diaphragm frame 3 is evenly opened with a plurality of side air exhaust holes 6 in the circumferential direction, and the base 4 has 5 large-sized central air ducts. One end of the diaphragm frame 3 is clamped to the outlet end of the base 4 and fixed by screws; the other end of the diaphragm frame 3 is connected to the mouth of the top cover 1 by bolts, and the diaphragm 2 is fixed between the two to realize the top cover. 1. The coaxial stacking connection of the diaphragm 2, the diaphragm frame 3 and the base 4.

[0025] In the center of the diaphragm 2 , the central guide sleeve 9 is fastened on the diaphragm 2 by a fixed sleeve 10 . The center of the top cover 1 is connected with an air guide tube 8, one end of the air guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com