Manpower car washing method

A manual, automotive technology, applied in vehicle maintenance, vehicle repair/repair, transportation and packaging, etc., can solve problems such as affecting car cleanliness, ignoring car windows, and impairing car wash efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

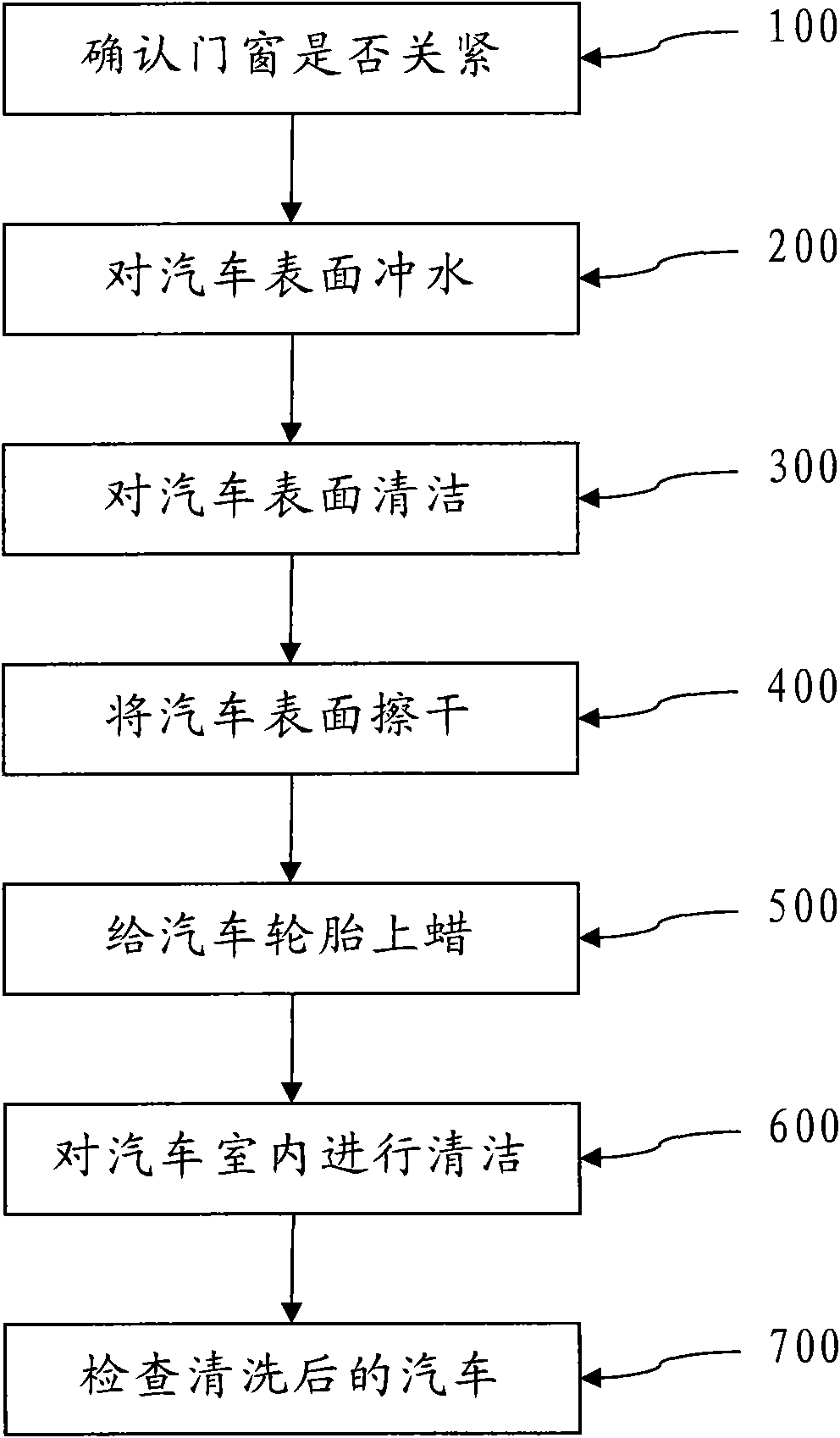

[0025] Such as figure 1 Shown is a flow chart of the basic steps of the car washing method according to the present invention. The method includes:

[0026] In step 100, a step of confirming whether the windows and doors are closed tightly is performed. This step includes: use your fingers to pinch the top of the window glass to see if there is a gap between the window and the window frame, so as to check whether the window is closed tightly; press and hold the door with your hand, so as to feel whether there is a gap between the door and the door frame uneven, so check that the door is closed tightly. This step prevents water and foam from penetrating into the vehicle interior during washing.

[0027] In step 200, the step of flushing the surface of the vehicle is performed. This step includes:

[0028] First, wash the lower part of the car (including the chassis and lower skirt), starting from the position farthest from the flushing equipment, and wash the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com