Plant fingerprint anti-counterfeit technique packaging method

A packaging method and fingerprint technology, applied in the field of anti-counterfeiting technology packaging, can solve the problems of wasting resources, consuming a lot of manpower, material resources, financial resources, increasing the discharge of harmful substances, etc., and achieve the effect of simple packaging structure, good anti-counterfeiting effect and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

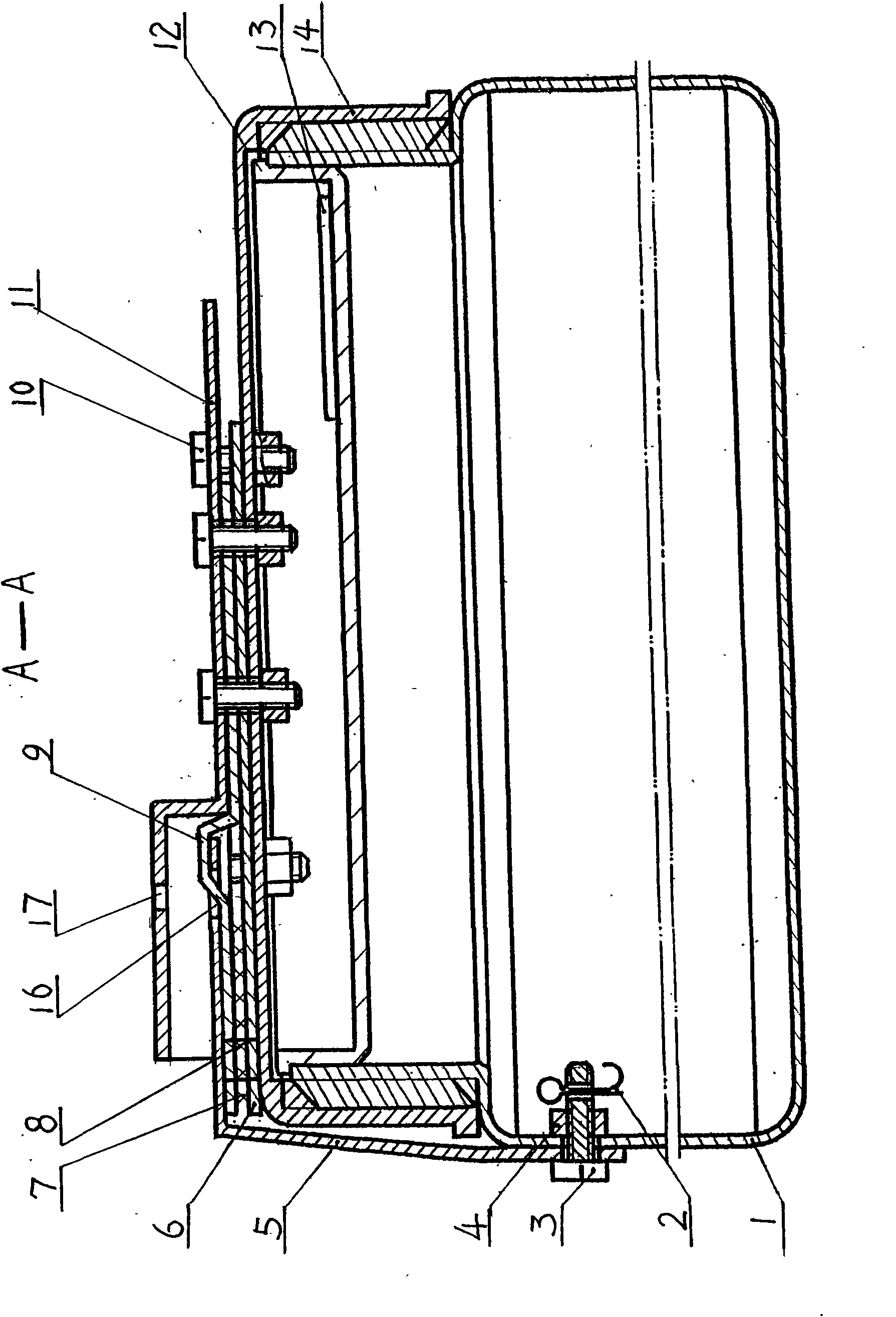

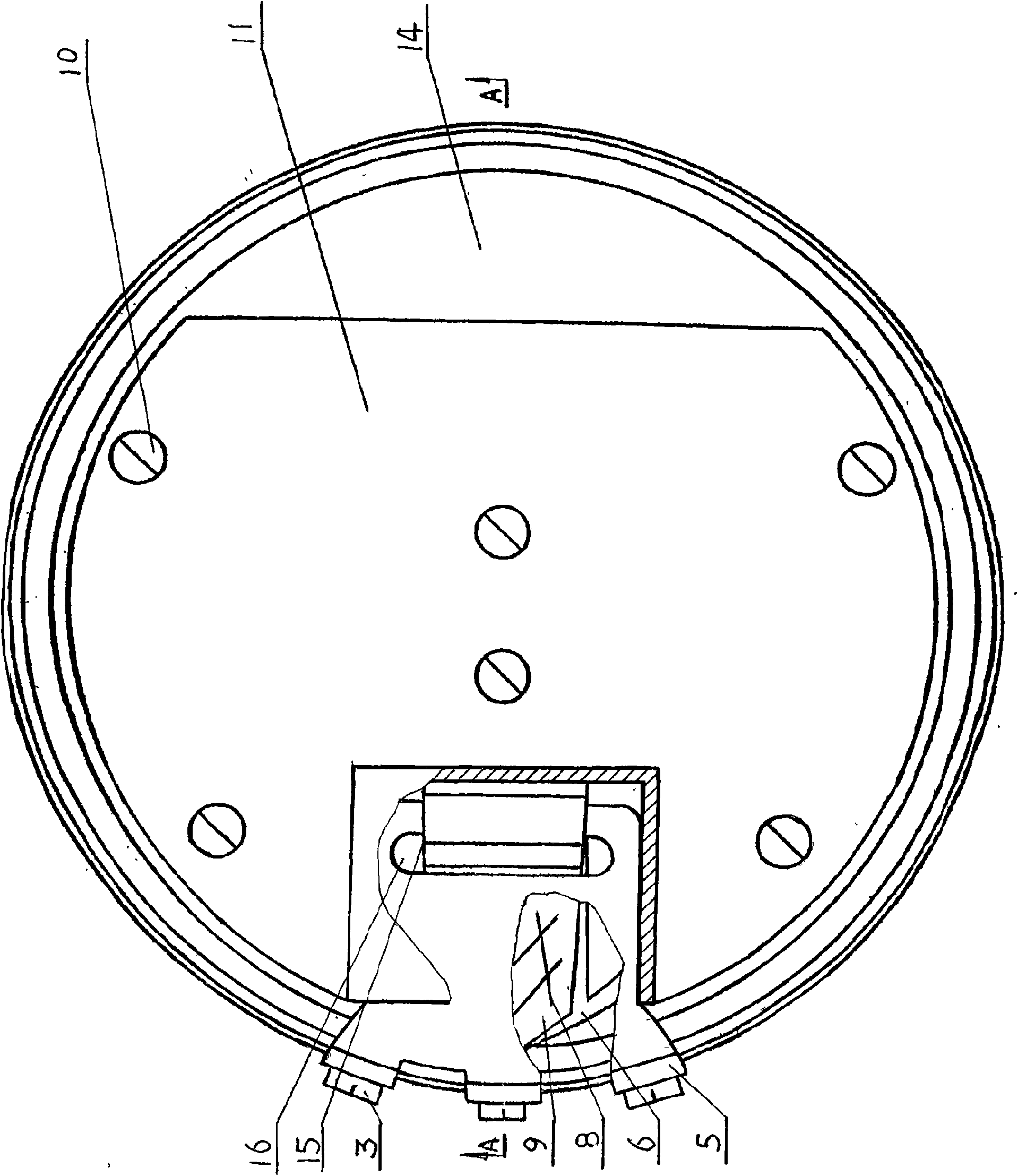

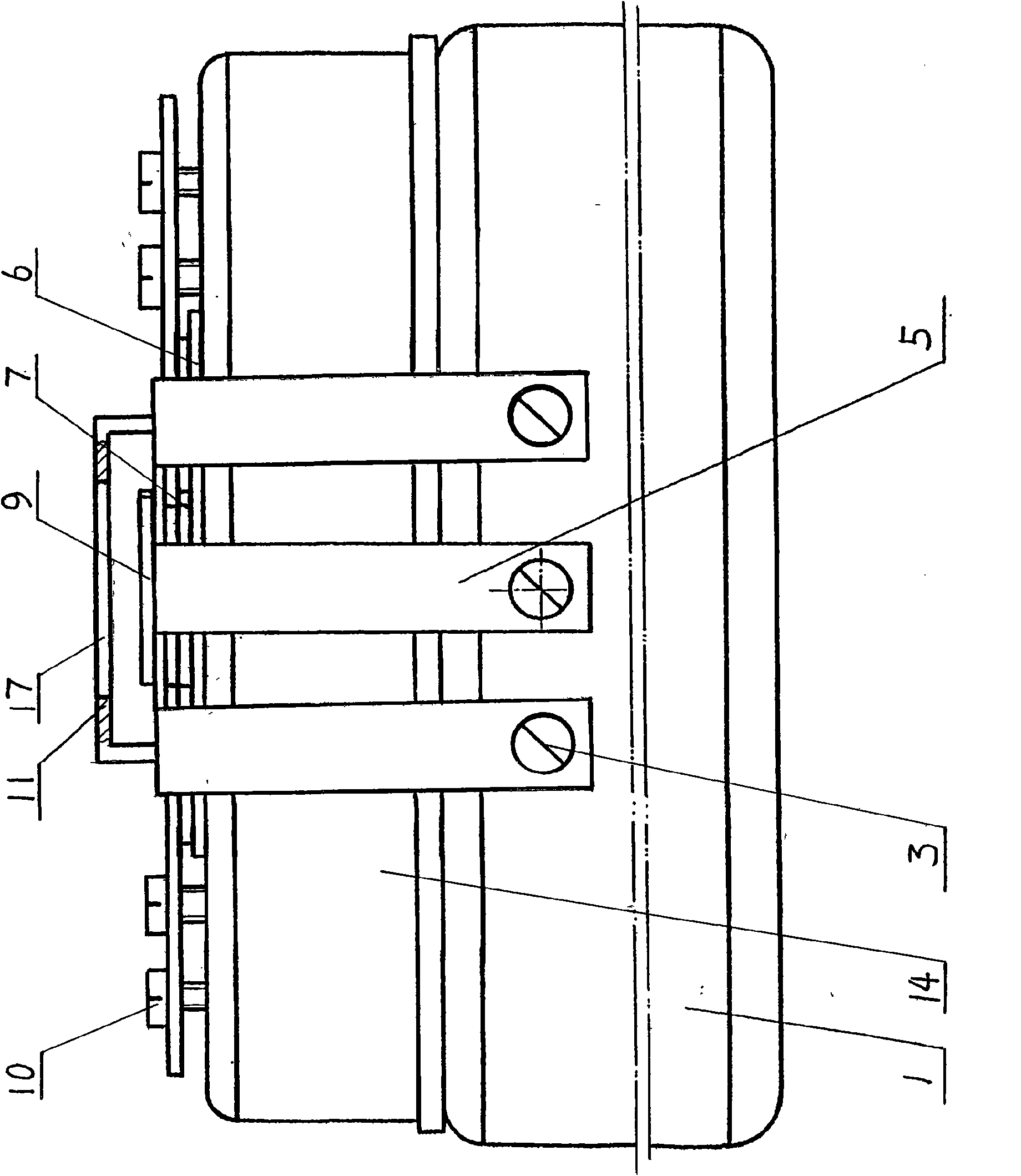

[0010] Such as figure 1 , figure 2 , image 3 As shown, install the inner cover 12 in the opening of the package body 1, place the stamped blanking edge 13 of the lock ring hinge 5 on the inner cover, and install the outer cover 14 through threads outside the opening, the effective number of turns is 3 turns, on the outer cover 14 Leaves 6 are placed, leaves 9 are placed on leaves 6, locking cover plate 11 is placed on leaves 9, and screws 10 and nuts 4 are locked on the top surface of the outer cover, and screws 3, The nut 4 is installed with the lock ring hinge 5, and the leaf 9 passes through the hole 16 on the lock ring hinge 5, and the leaves 9 and the leaves 6 below the lock ring hinge 5 are bonded with each other by glue 7, and the locking cover plate 11 is formed at one time. Parts, lock ring hinge 5 is an aluminum sheet shape, distribution screw 10 mounting holes on the locking cover plate, there is a broach crossing 17 facing the leaf 9 through the hole 16 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com