Escalator handrail

A handrail and escalator technology, which is applied in the field of escalator components, can solve the problems of low load-carrying capacity, low safety factor, and potential safety hazards of escalator handrails, and achieve the effects of increasing rigidity, increasing bearing capacity, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

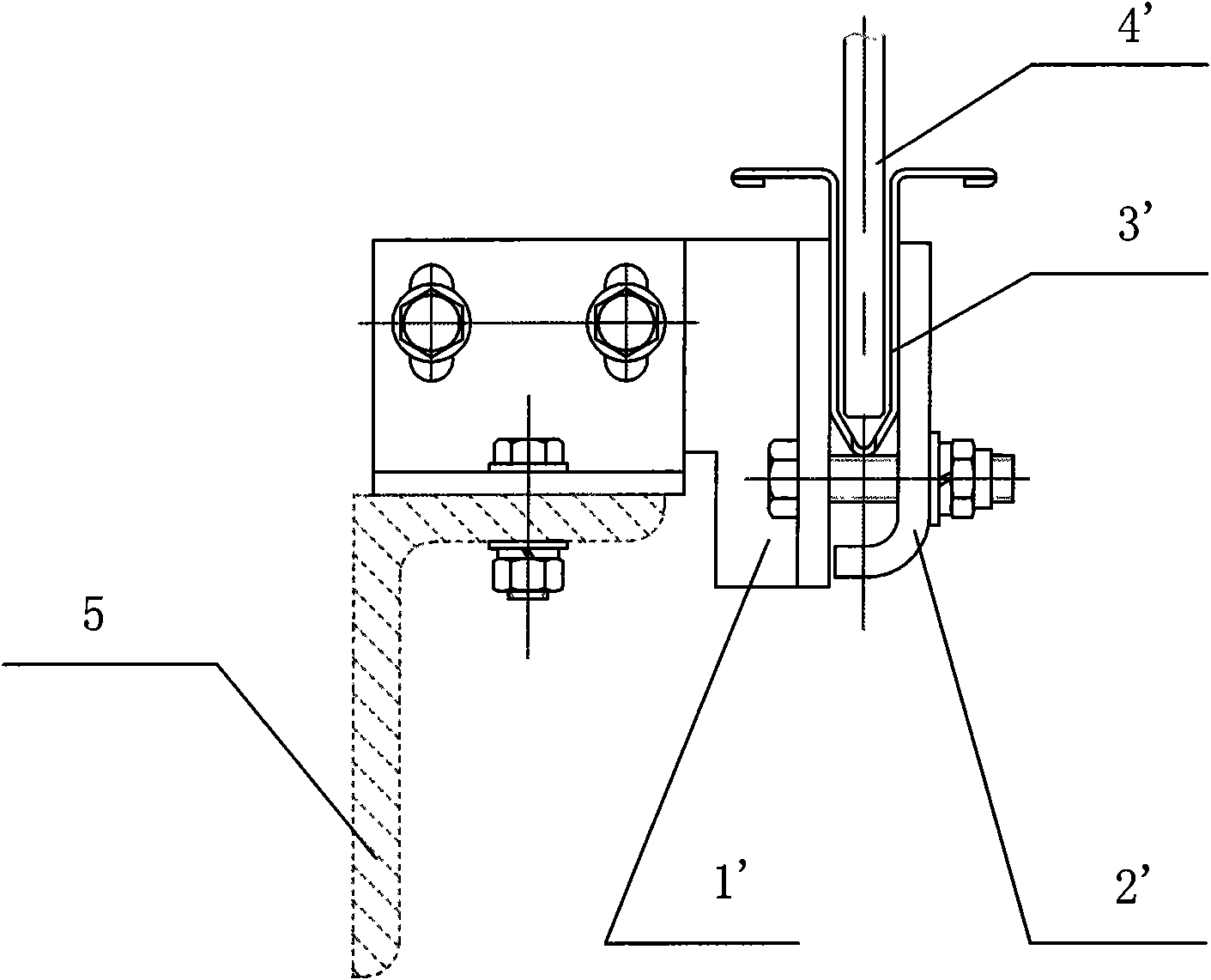

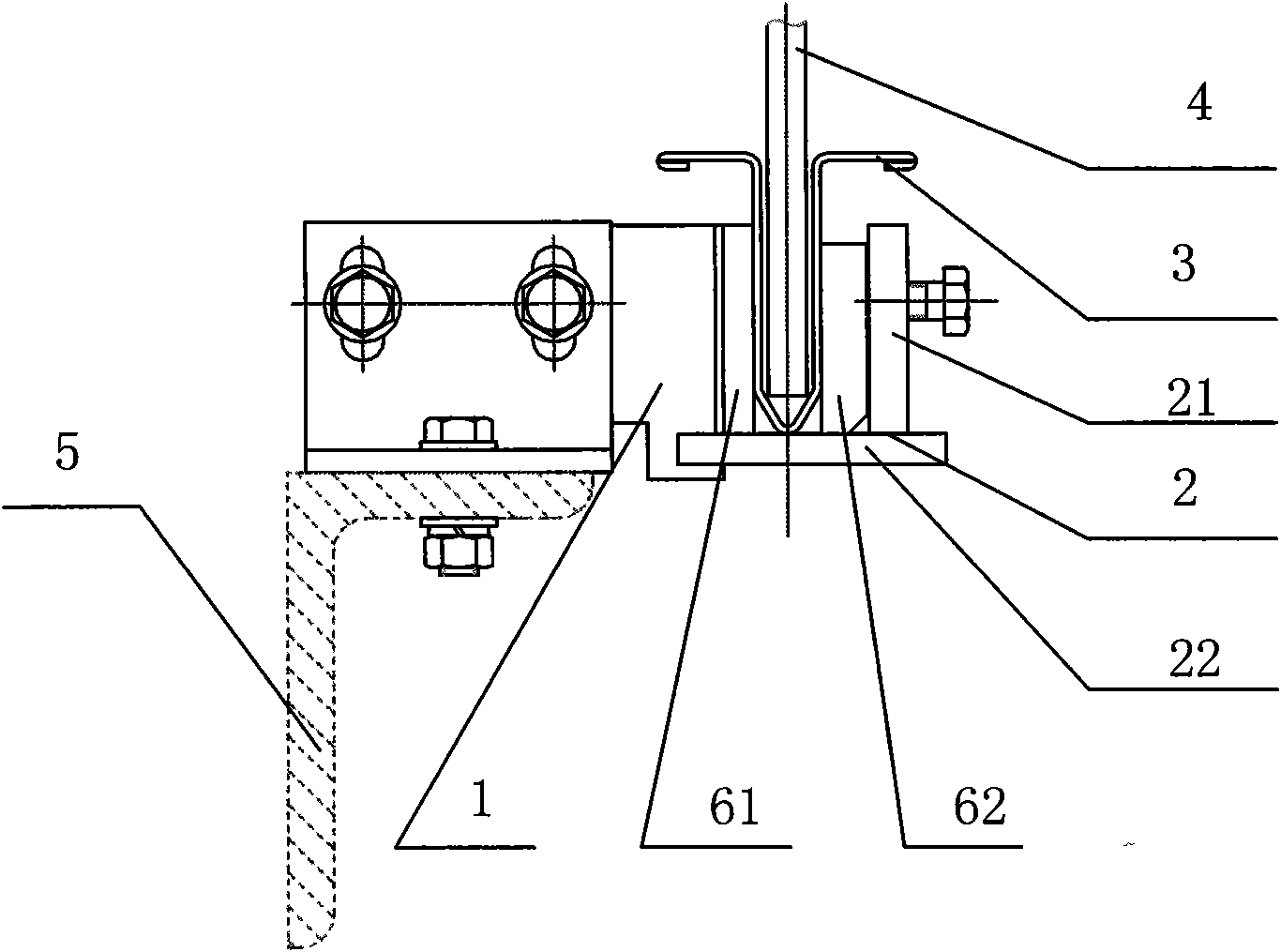

[0016] Such as figure 2 As shown, the escalator handrail of the present invention relates to an escalator truss 5, including a baseboard support fixedly connected to the truss 5, and the basement support includes a fixed plate 1 and an outer guard plate 2 connected to the fixed plate 1 , the baseboard clamping part 3 and the baseboard 4 placed in the baseboard clamping part 3 are pressed between the fixed plate 1 and the outer sideboard 2, and the baseboard 4 used in the present invention is a glass plate, and the The outer guard plate 2 is in an "L" shape, and it includes a vertical plate 21 connected to each other and a horizontal plate 22 for receiving the clapboard clamping part 3. The horizontal plate 22 and the vertical plate 21 are connected into one body by welding, so The end of the horizontal plate 22 is placed in the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com