Early-demounting template system applied to building containing beam, plate and column structure on floor slab

A technology for early dismantling of formwork and column structures, which is applied to the preparation of building components on site, construction, building construction, etc., can solve problems such as construction efficiency limitations, and achieve the effect of easy operation and use, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

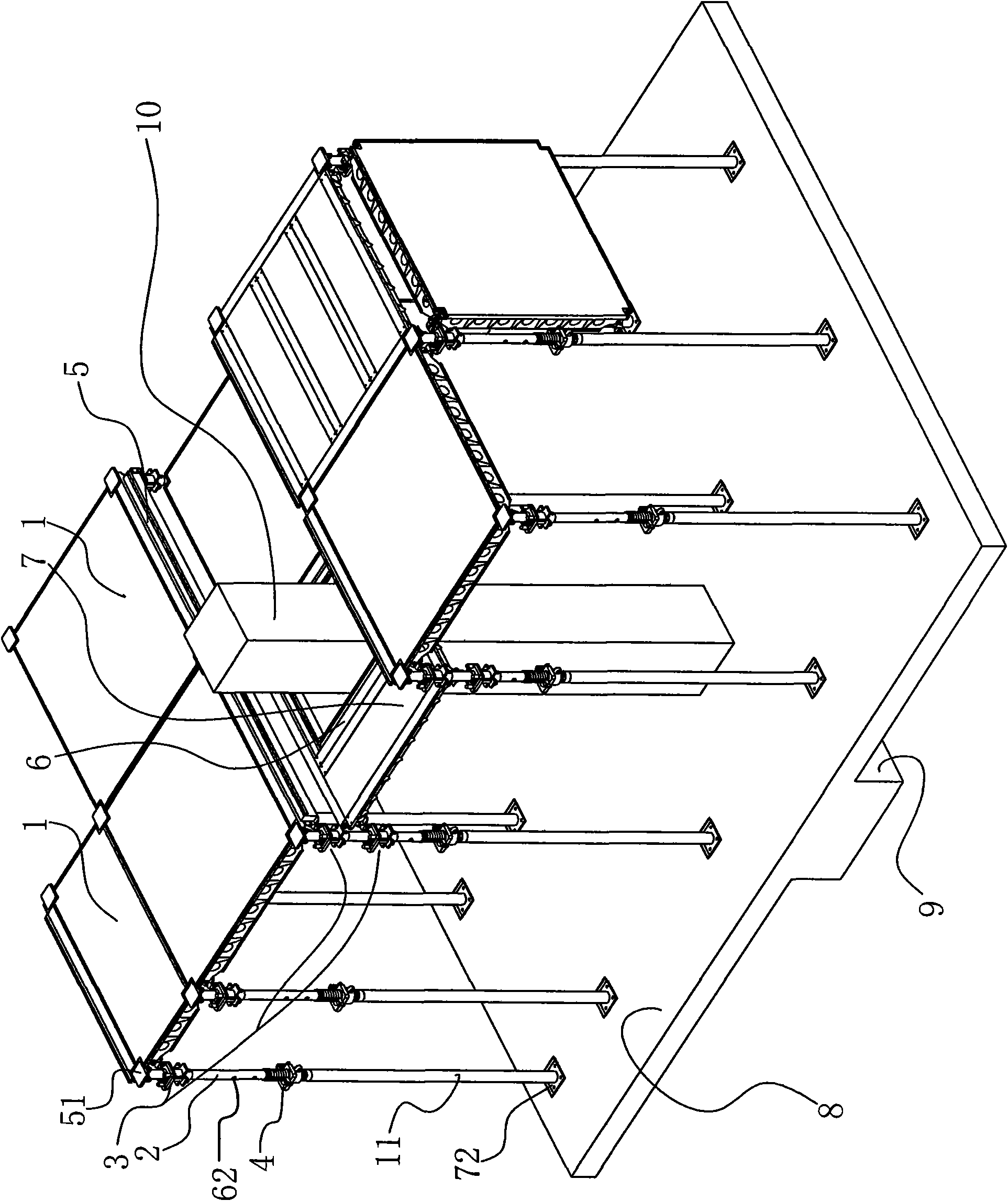

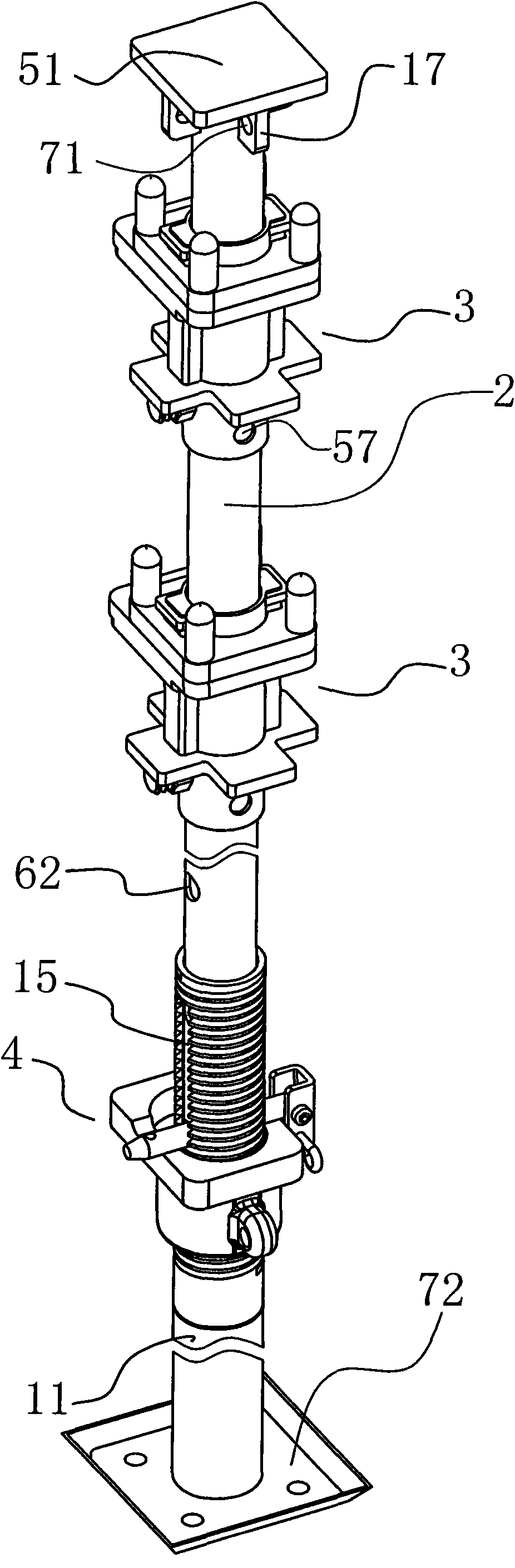

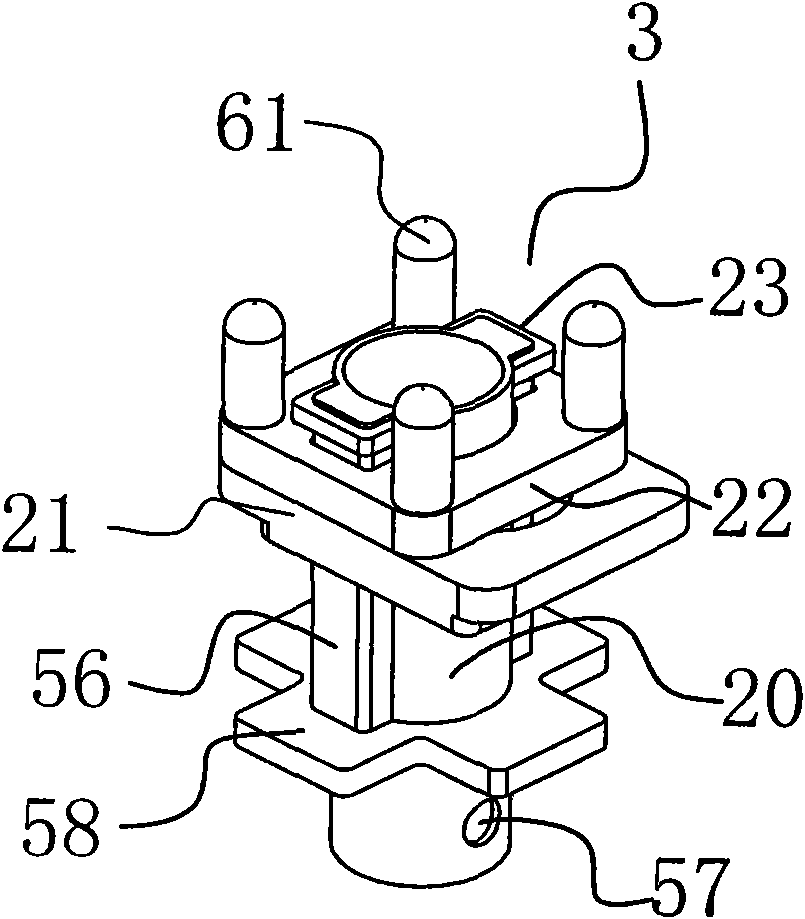

[0060] see figure 1 , figure 2 , an early demolition formwork system for buildings with beams, slabs and columns on the floor, mainly includes a formwork 1, an early demolition support column 2, and a rectangular top plate 51 is fixedly connected to the top of the early demolition support column 2, and is characterized in that: At least one early removal mechanism 3 is set on the early removal support column 2; the early removal support column 2 is provided with at least one through hole 62, and the lower end of the early removal support column 2 passes through the through hole 62 and the upper end of the outer tube 11 in the unloading mechanism 4 Connection; the four corners of the template 1 are connected with L-shaped corners 25 .

[0061] see Figure 12 , Figure 13 , the L-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com