High-pressure roller mill for metal ore

A high-pressure roller mill and high-pressure roller technology, used in grain processing and other directions, can solve the problems of complex transmission mode, difficult to replace the roller surface, and the maximum efficiency is not more than 10%, so as to achieve reasonable system design, improve production capacity, and avoid disadvantages. effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

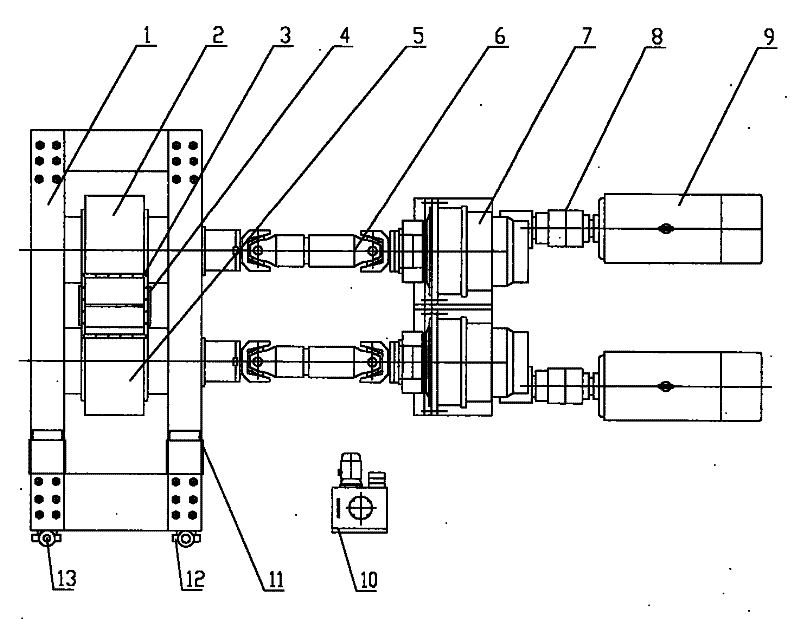

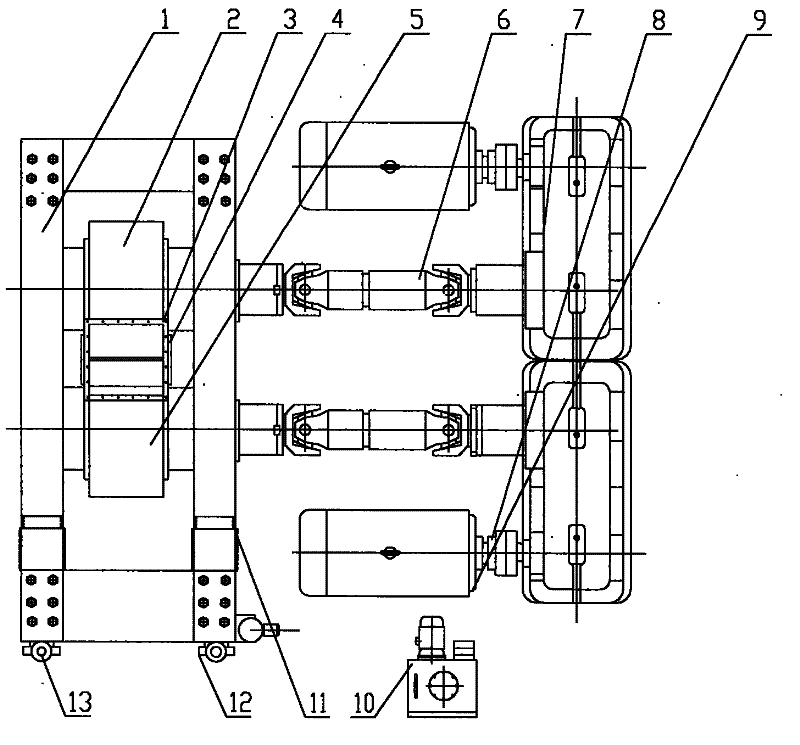

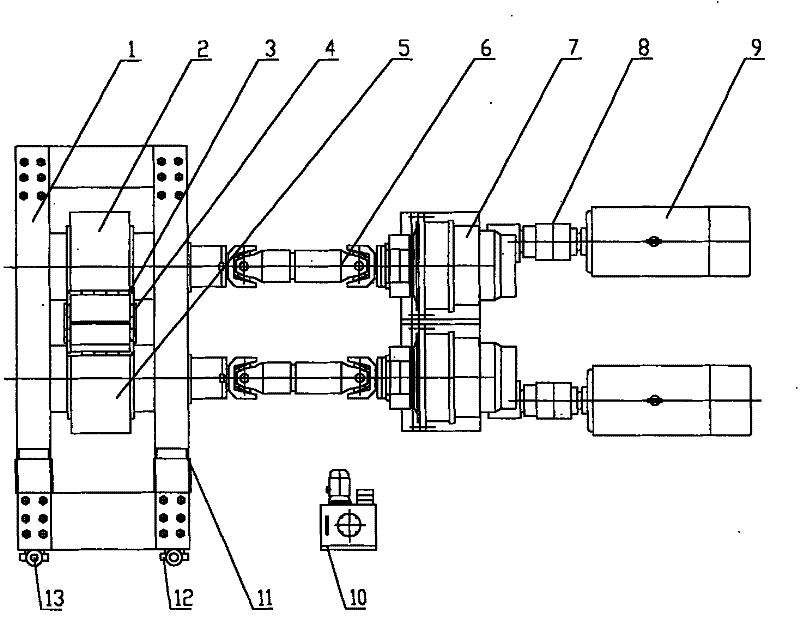

[0012] The present invention will be further described in detail below in conjunction with the drawings:

[0013] Two sets of high-pressure roller devices 2 and 5 are horizontally installed side by side on the frame 1. Each set of high-pressure roller is equipped with its own independent transmission device, which passes through the main motor 9 through the reducer 7 and then through the universal drive shaft 6 and the high pressure roller. The roller devices 2 and 5 are connected and rotate towards each other. One set of high-pressure rollers is fixed (called static roller 2), and the other set can slide in the horizontal direction (called moving roller 5).

[0014] Four sets of pressure cylinders 11 are installed on one side of the movable roller 5, and the power source is provided by a separate hydraulic station 10. The high-pressure oil output from the hydraulic station 10 is connected to the frame 1 through a high-pressure oil pipe after passing through a control valve. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com