Leak detection device for big soft infusion bag production line

A large infusion and production line technology, applied in transportation and packaging, liquid tightness measurement using liquid/vacuum degree, packaging, etc., can solve problems such as waste of raw materials, uneven mouth tube, uneven mouth tube of bag film, etc. Achieve the effect of improving reliability and stability, saving use cost and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

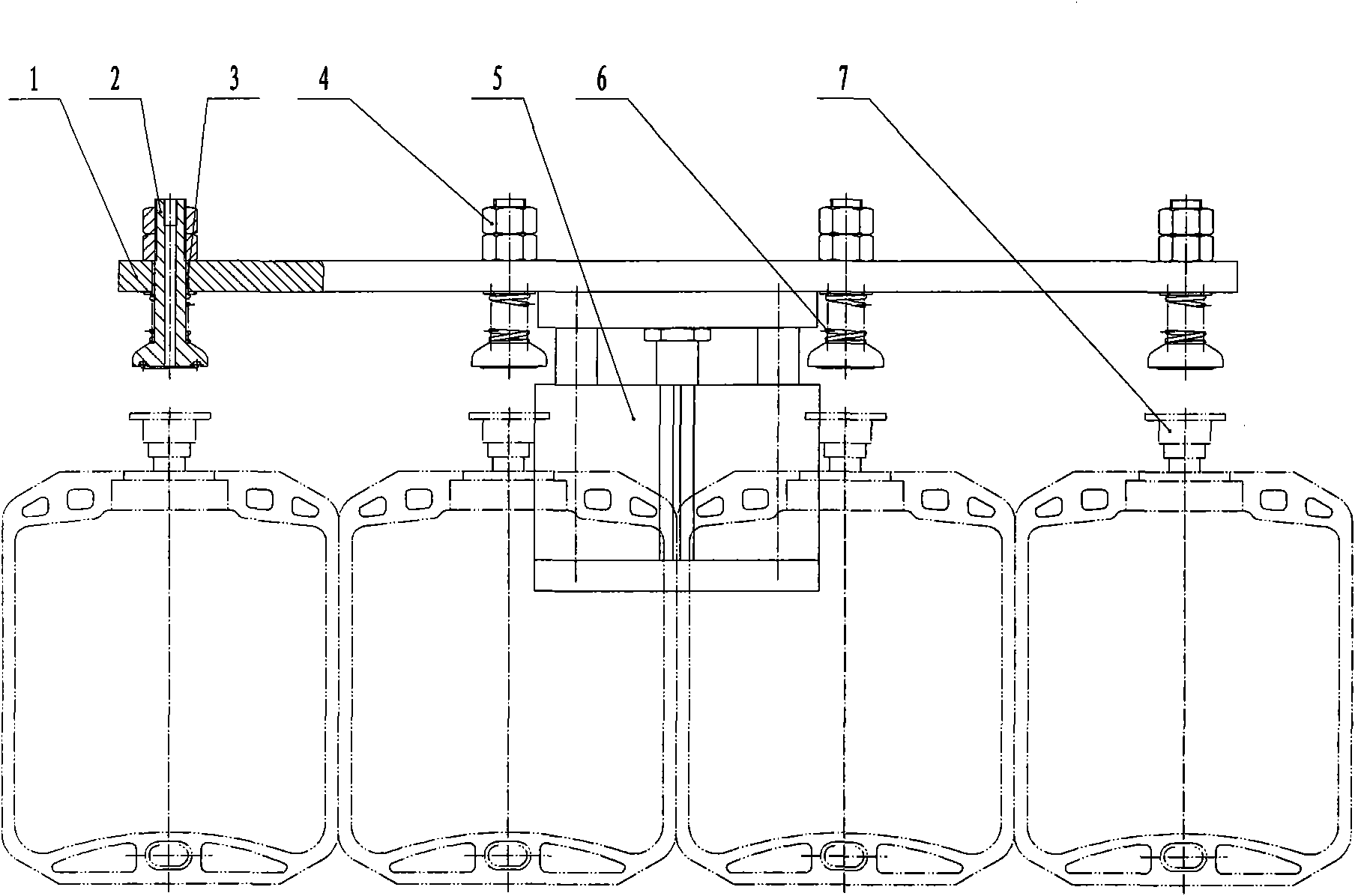

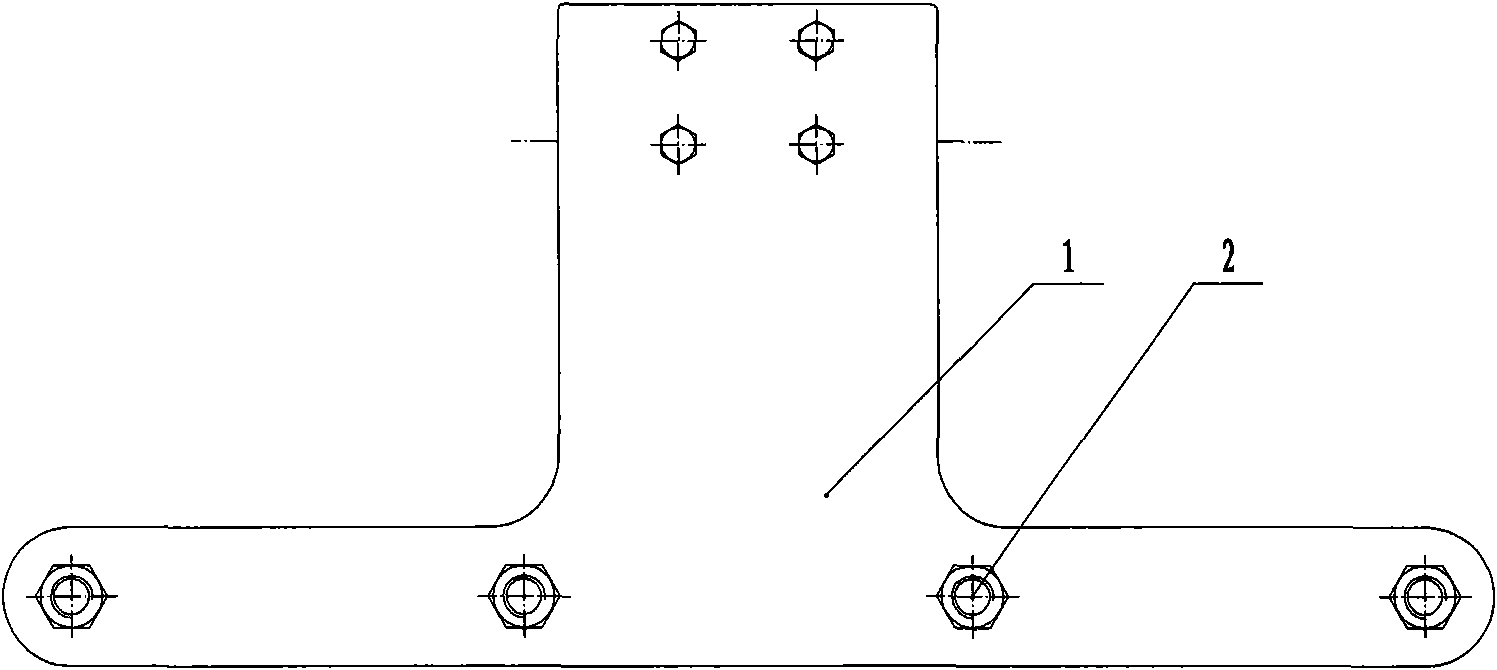

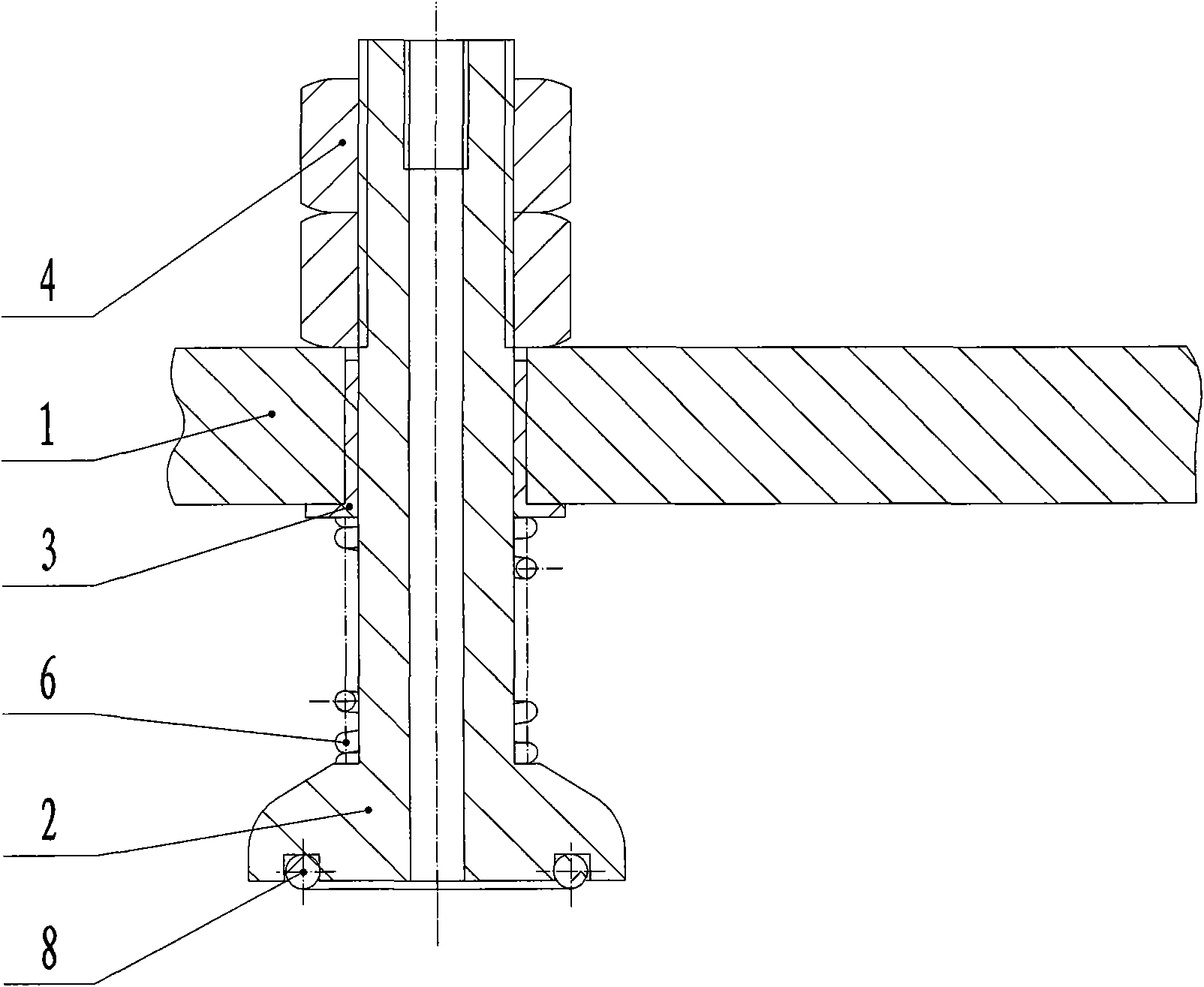

[0023] Such as figure 1 , figure 2 and image 3 As shown, the present invention is used for the leak detection device of soft bag large transfusion production line, and it comprises installation frame 1, more than one detection head 2 and drive mechanism 5, and installation frame 1 links to each other with drive mechanism 5, and drive mechanism 5 adopts cylinder, and cylinder The up and down movements drive the mounting frame 1 to move up and down; the movable independent detection head 2 is fixed in the mounting hole on the mounting frame 1 through the connector 3, and the number of detection heads 2 is the same as the number of film bags 7 to be inspected ( The number of bags produced in one working cycle of the production line) is the same, so that each film bag 7 to be inspected is equipped with an independent detection head 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com