Automatic dredging device for waste incineration power plant leachate grating plates

A technology of waste incineration and grid plate, which is applied in the direction of contaminated groundwater/leachate treatment, special treatment targets, water/sewage treatment, etc., and can solve problems such as increasing incineration costs, diffusion of odorous gases, and reducing the calorific value of waste. Achieve the effects of improving operational efficiency and safety, improving dredging efficiency, and improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

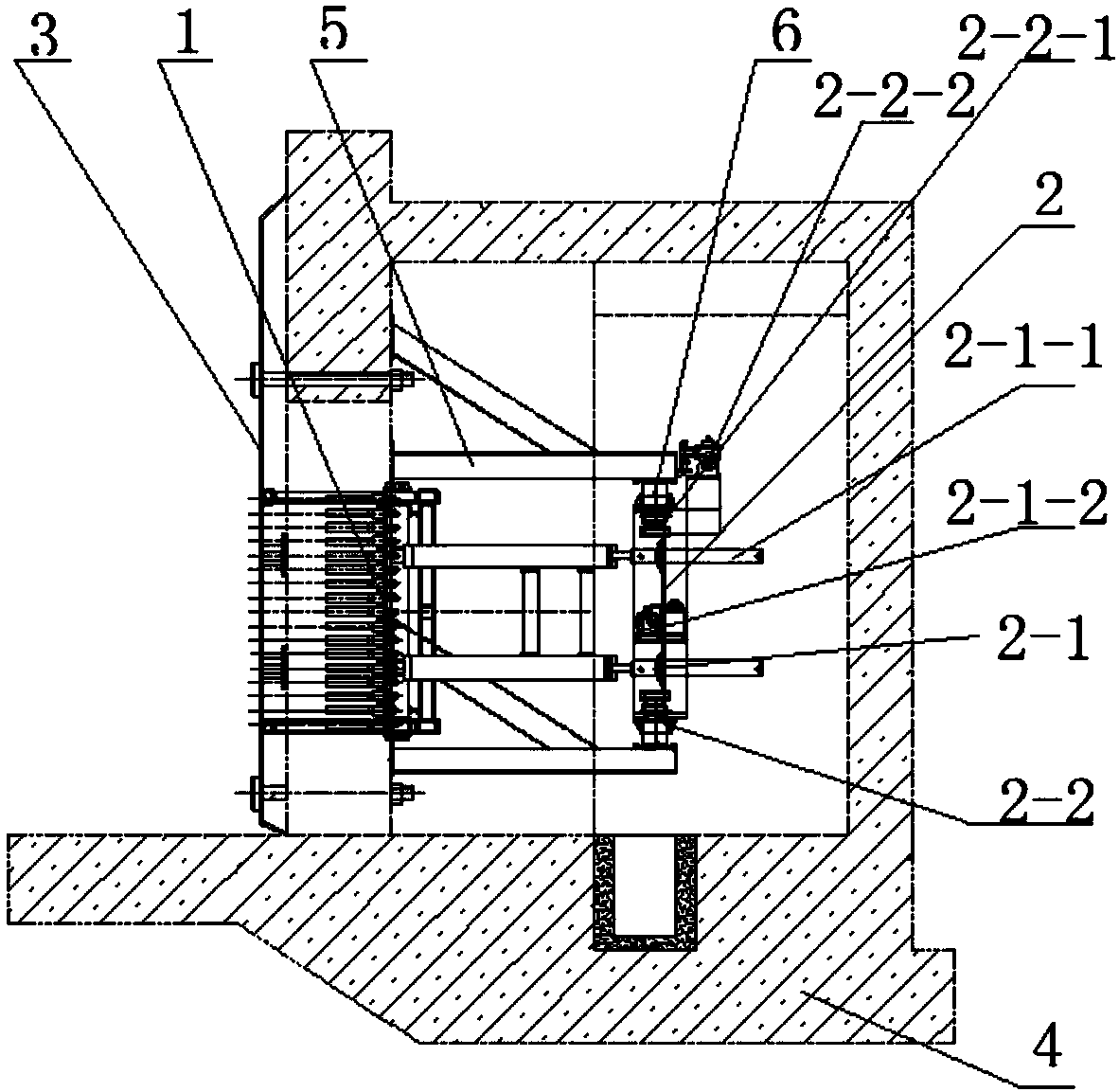

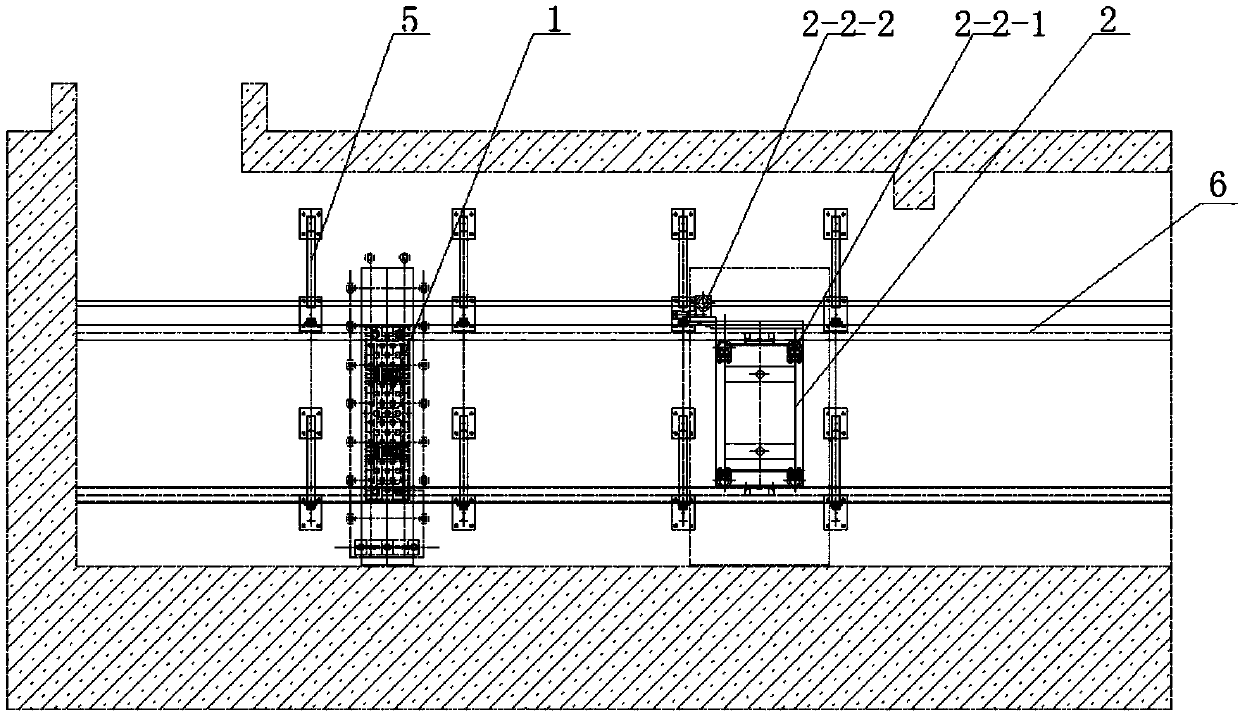

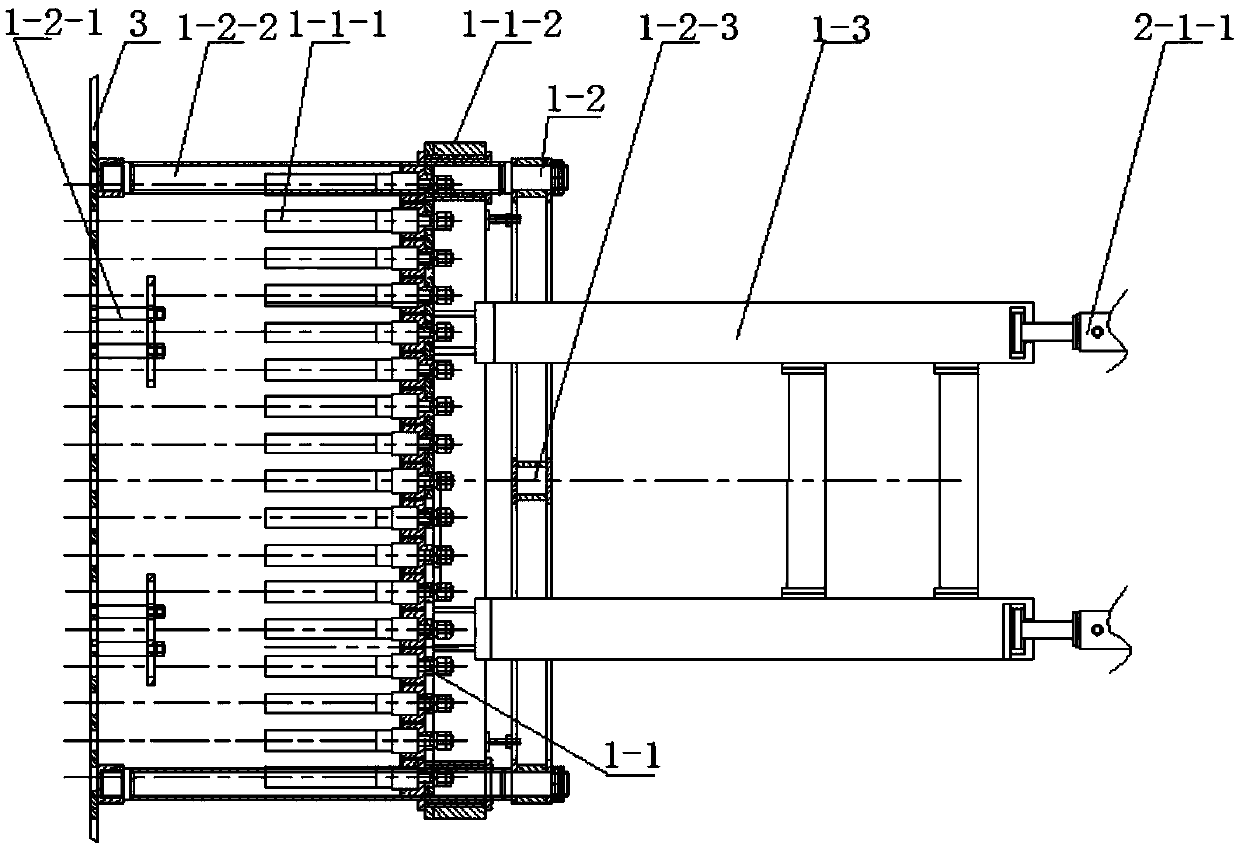

[0026] An automatic dredging device for leachate grid plate in a waste incineration power plant as described in the accompanying drawings, including a dredging actuator 1 and a mobile frame 2; the dredging actuator 1 includes a ejection structure 1-1 and a guiding structure 1 -2 and the transmission structure 1-3; the grid plate 3 is fixed on the wall 4; the plurality of dredging actuators 1 are installed on the grid plate 3, corresponding to the grid plate 3; the ejection The structure 1-1 is arranged corresponding to the grid hole; the ejection structure 1-1 can reciprocate along the guiding path of the guiding structure 1-2, perpendicular to the grid plate 3; the mobile frame 2 can move along the grid The distribution direction of the plates 3 moves; when the mobile frame 2 is displaced to the corresponding position of the dredging actuator 1, the ejection structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com