Processing unit of sewing cloth and processing method

A processing device and cloth technology, which is applied in the processing of textile materials, spraying/jetting textile materials, processing textile material carriers, etc., can solve the problems that hinder the simplification of devices, and achieve the effect of improving stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

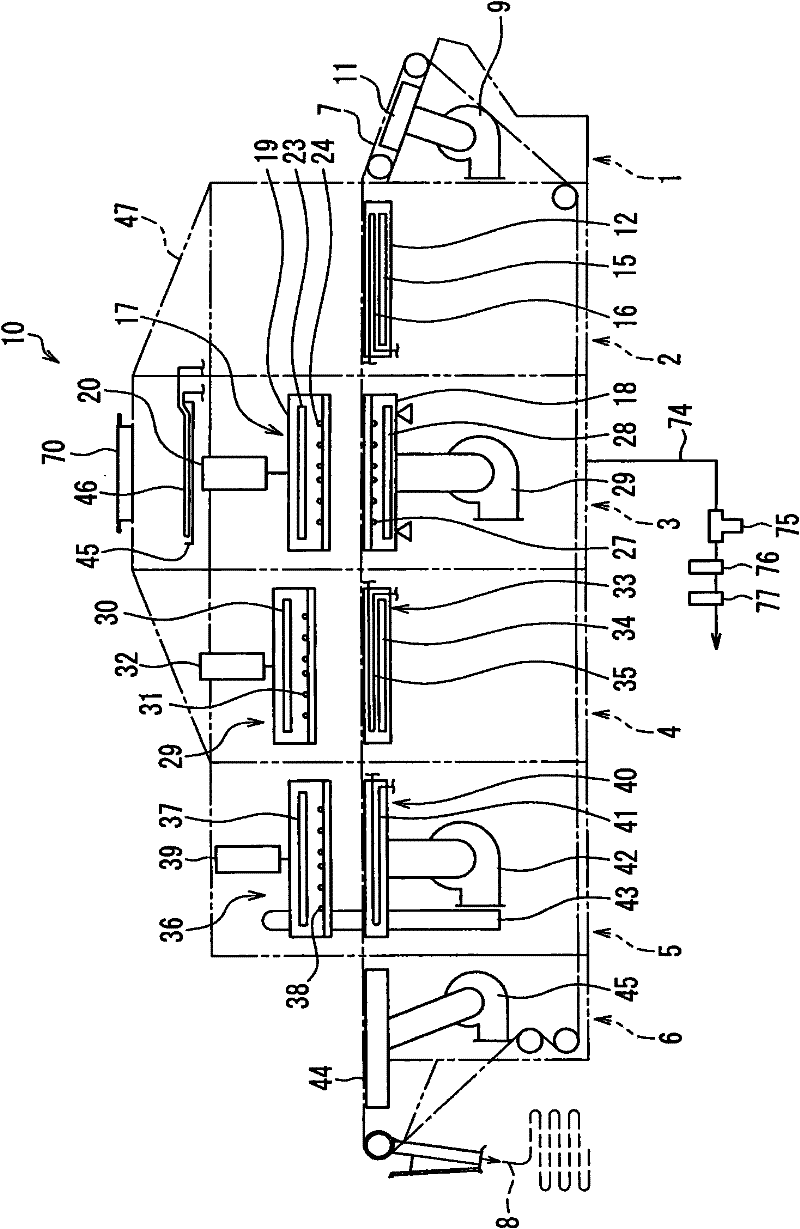

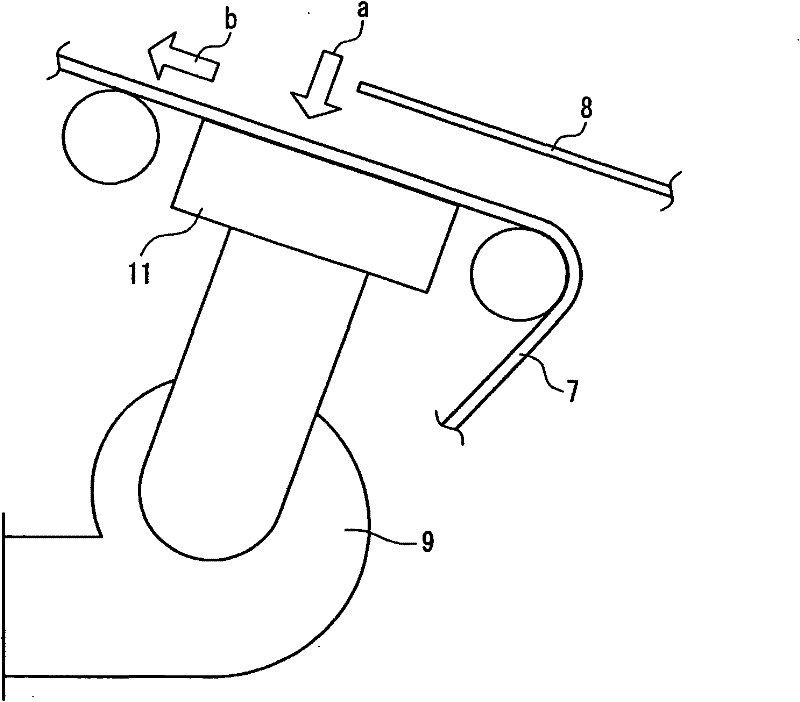

[0030] According to the processing device and processing method of the sewn cloth of the present invention, it is possible to perform processing to improve the stability of the cloth, and since the conveyor belt is one, and each mechanism is connected in a recombinable manner, it can be made into a simple structure, and Versatility capable of handling a variety of fabrics can be realized.

[0031] In the above-mentioned processing device of the present invention, it is preferable that the above-mentioned moist heat pressing mechanism presses the cloth and the above-mentioned one conveyor belt integrally.

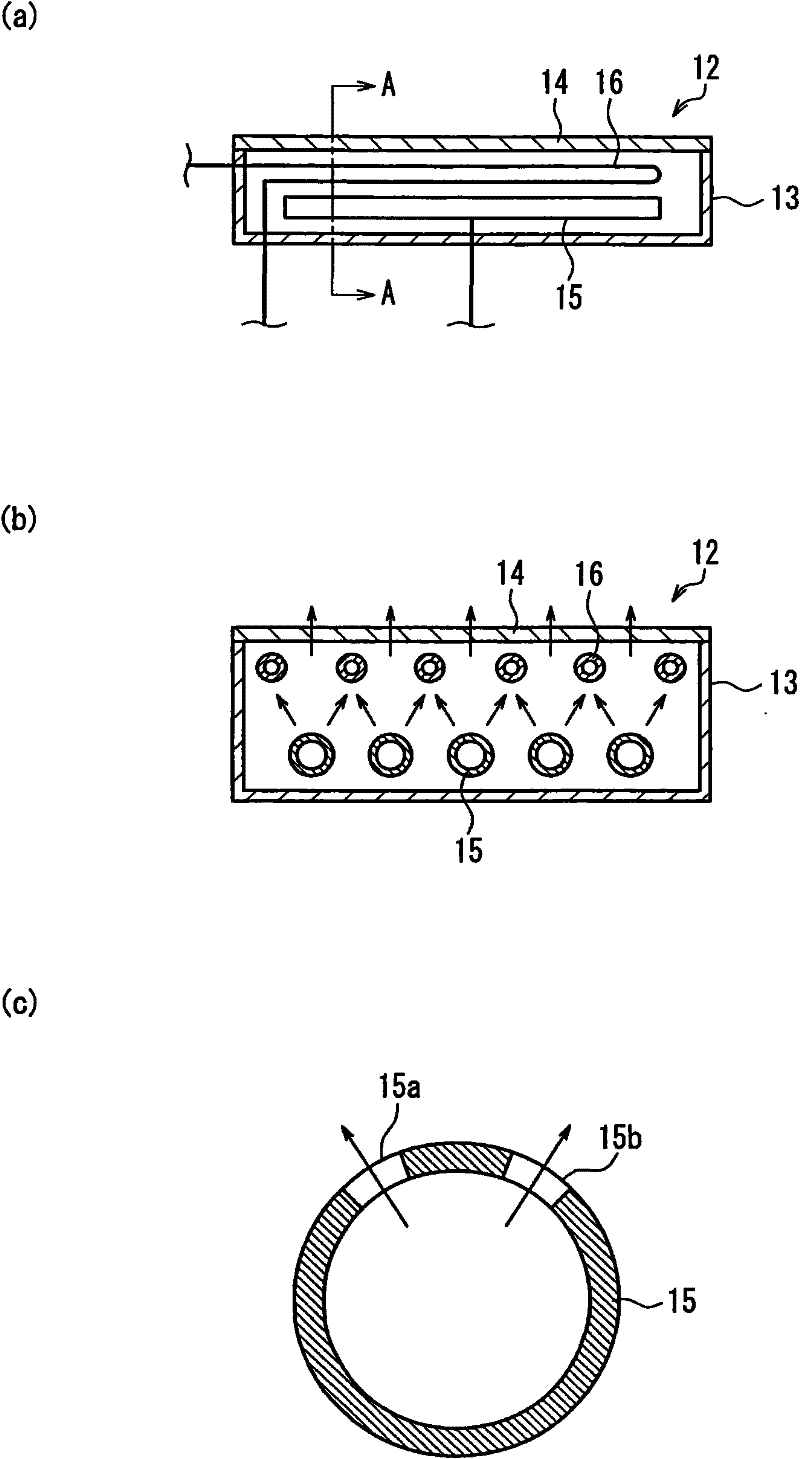

[0032] In addition, it is preferable that the above-mentioned pressing of the above-mentioned moist heat pressing mechanism accommodates a steam injection pipe in a box-shaped body including a pressing surface, and the above-mentioned steam injection pipe is provided with a plurality of injection holes so that steam is diffused and sprayed at the same time. The above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com