Drive circuit of light emitting diode

A technology of light-emitting diodes and driving circuits, which is applied to semiconductor devices of light-emitting elements, circuit layout, electric lamp circuit layout, etc., can solve problems such as inability to accurately adjust brightness and different target brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

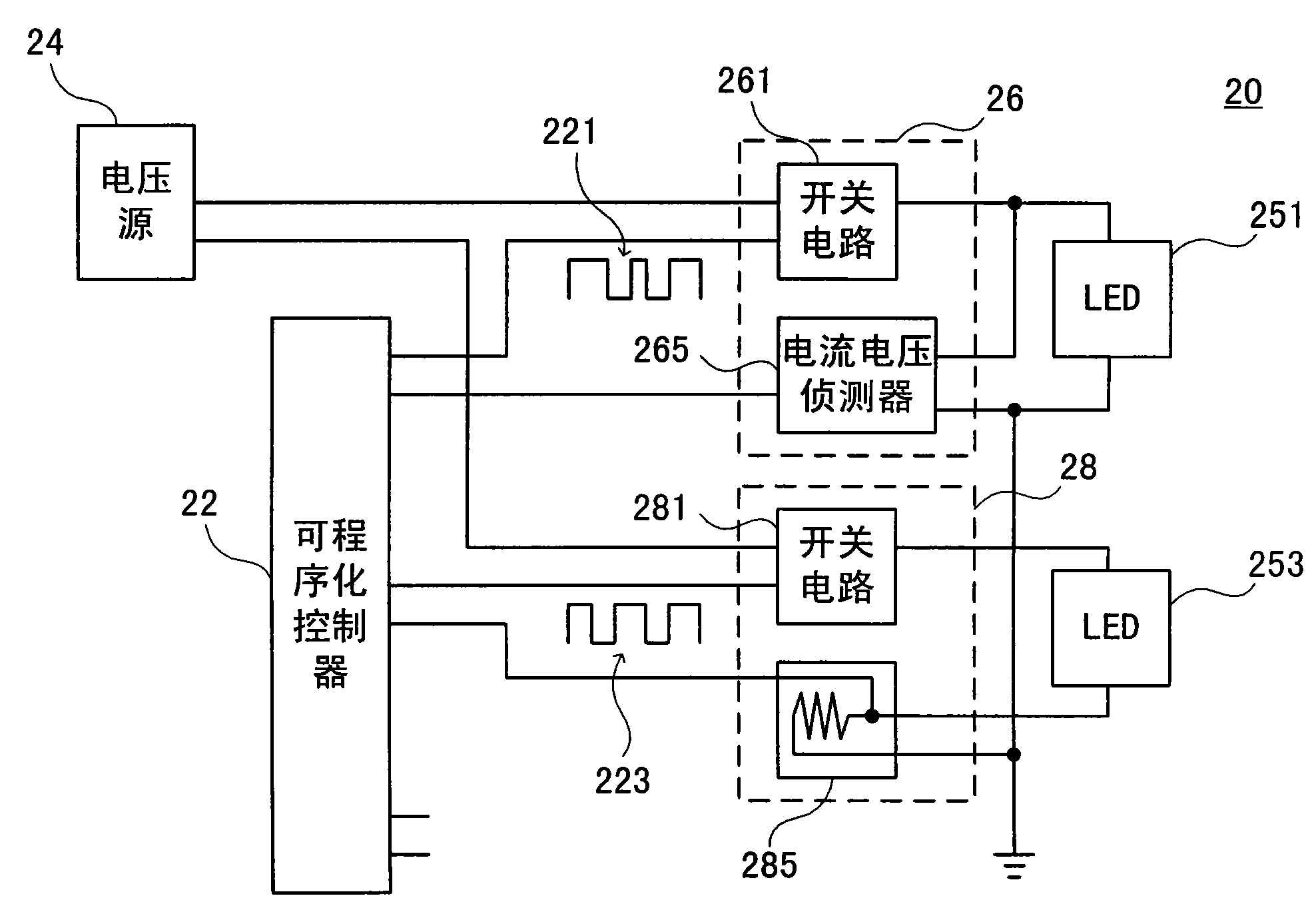

[0054] see figure 2 , is a circuit block diagram of a preferred embodiment of the present invention. As shown in the figure, the driving circuit 20 of the light emitting diode (LED) of the present invention mainly includes a voltage source 24, at least one driving module (26, 28), at least one LED (251, 253) and a programmable controller twenty two. In this embodiment, two sets of drive modules 26 and 28 are used as an example for illustration.

[0055] Wherein, each driving module 26 , 28 includes a switch circuit 261 , 281 and a current and voltage detector 265 , 285 respectively, and each driving module 26 , 28 is connected to an LED 251 , 253 respectively. Wherein, the LED 251 and 253 can be one LED, or multiple LEDs connected in series or in parallel.

[0056] The switch circuits 261, 281 of the driving modules 26, 28 are respectively connected to the voltage source 24, and the LEDs 251, 253 and the corresponding current and voltage detectors 265, 285 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com