Sensing device of disassembly of fastener and sensing method

The technology of a sensing device and sensing method, applied in the field of sensing, can solve problems such as prone to collapse, casualties, theft and tower damage, and achieve the effects of good environmental adaptability, high reliability, and strong real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

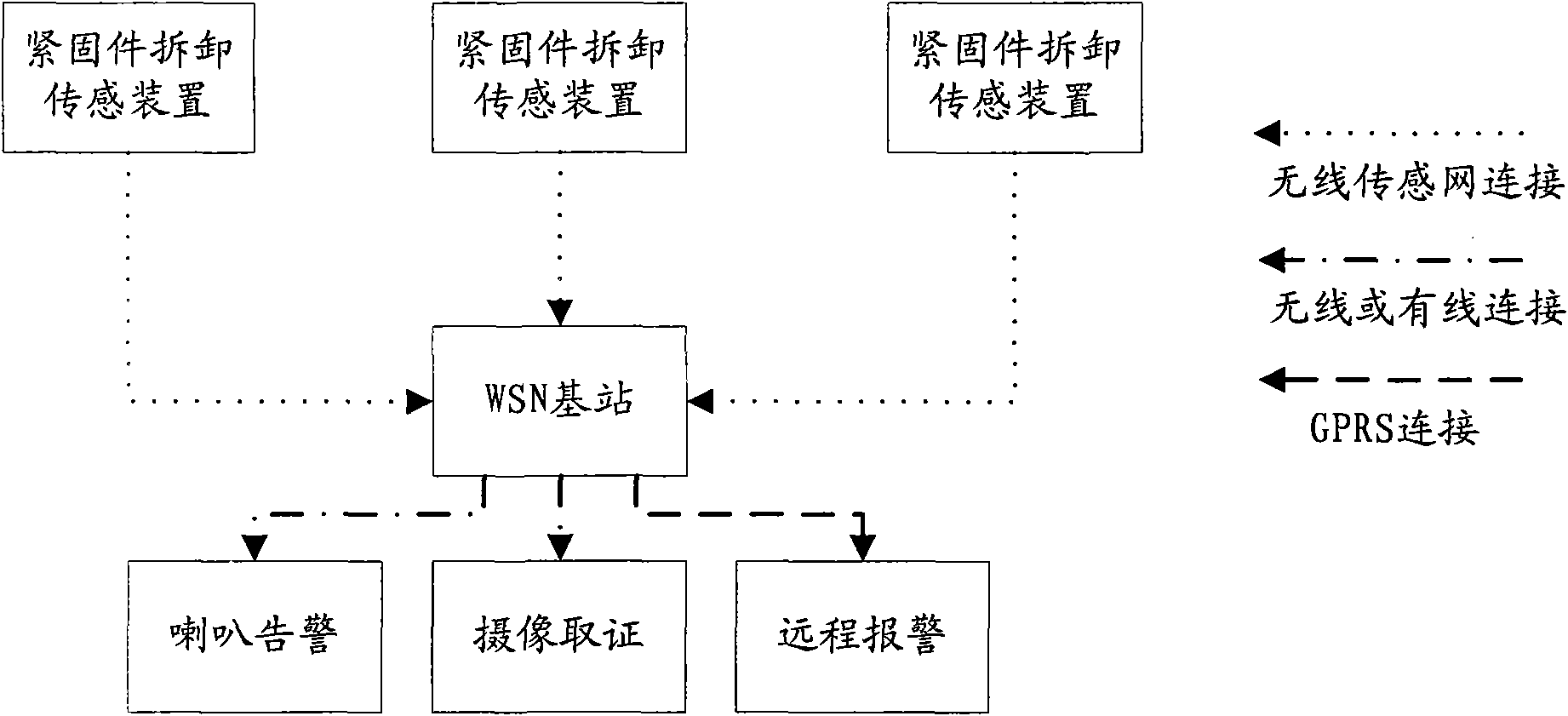

[0033] This embodiment is a fastener removal sensing device, wherein the fastener includes a first element and a second element; the second element cooperates with the first element to play a fixing role.

[0034] The fastener removal sensing device is used to sense whether the fastener is disassembled, including an induction unit and a sending unit arranged on the first element; the induction unit is used to sense the displacement of the second element or the second unit and the Whether the relative displacement of the first unit changes; the sending unit is used to send out the abnormal information sensed by the sensing unit.

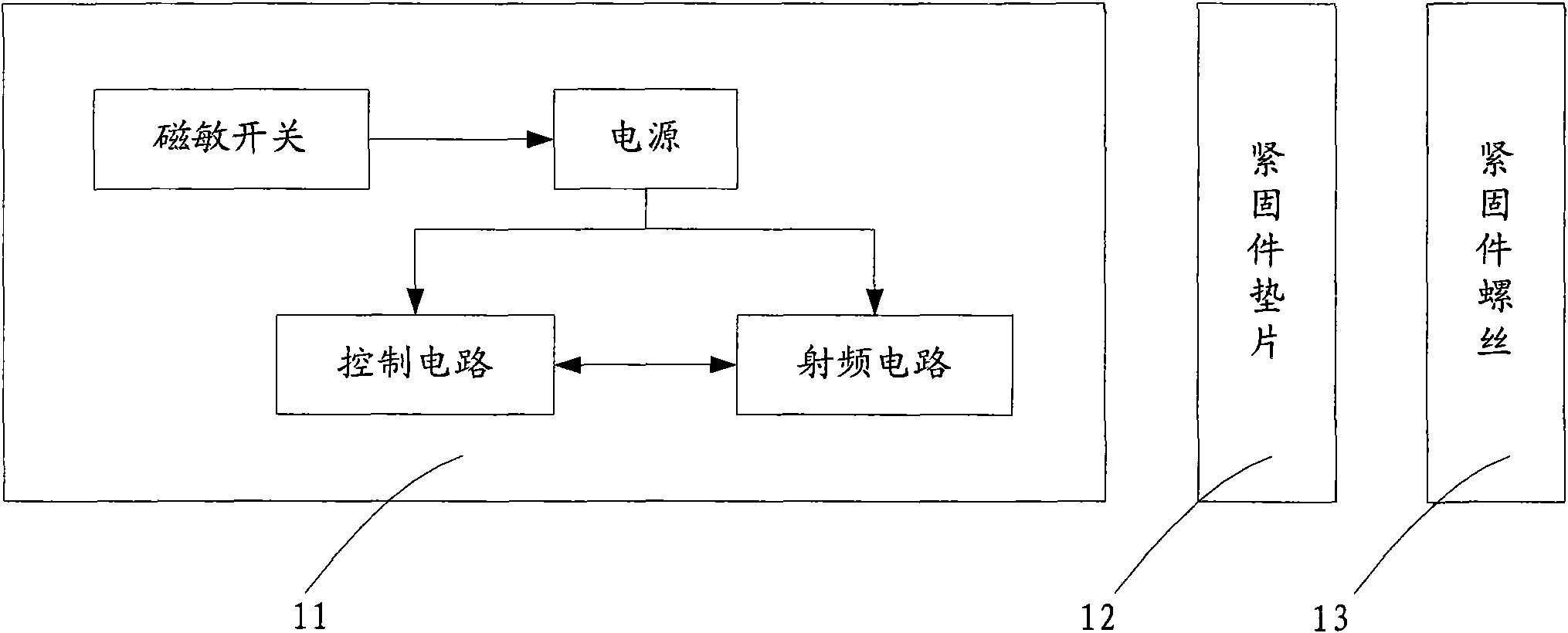

[0035] The fastener disassembly sensing device includes a power supply; the sending unit includes a radio frequency circuit and a control circuit; the radio frequency circuit is used to send disassembly information of the fastener; the control circuit is connected to the radio frequency circuit through the SPI bus to control Sending of fastener disass...

Embodiment 2

[0044] The difference between this embodiment and embodiment one is as figure 1 As shown, the first element is a fastener nut 11 , the second element is a fastener washer 12 , and the fastener further includes a third element which is a fastener screw 13 .

[0045]The fastener washer 12 is a magnetic washer. The fastener nut 11 is provided with a sensor, a control circuit, a radio frequency circuit and a power supply; the radio frequency circuit is used to send disassembly information of the fastener; the control circuit is connected to the radio frequency circuit through the SPI bus to control Sending of fastener removal information; the sensor is used to sense the position of the fastener gasket 2 to determine whether the fastener has been removed, and to control the power supply of the control circuit and the radio frequency circuit. The fastener washer 2 is a magnetic element. The sensor is a magnetic sensitive switch. The radio frequency circuit includes a radio freque...

Embodiment 3

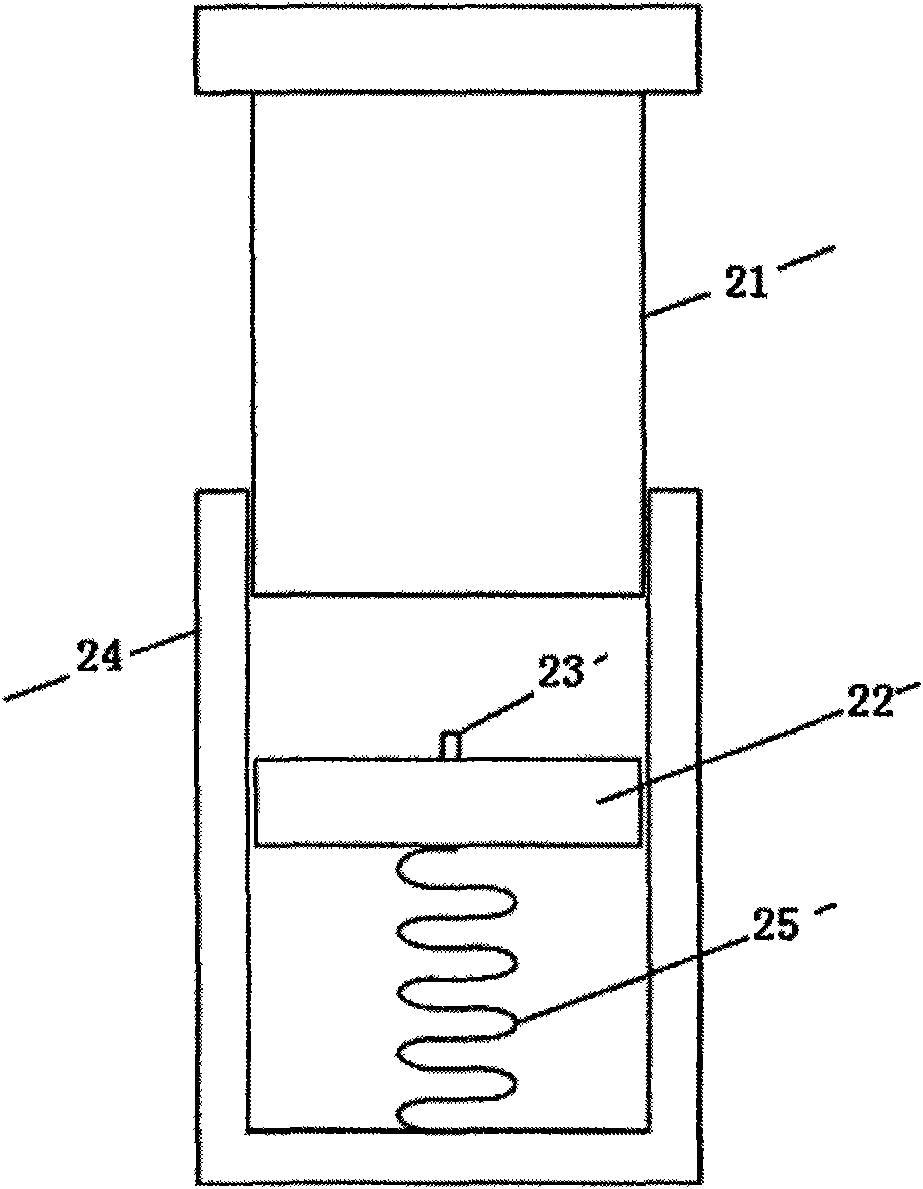

[0053] The difference between this embodiment and the previous embodiment is as figure 2 As shown, the first element is a nut, the second element is a screw 21, the induction unit 22 is arranged in the nut, the induction unit 22 is provided with a switch 23, and the switch 23 is screwed into the nut by the screw 21 When pressed by the screw 21, the internal circuit of the induction unit 22 is disconnected.

[0054] One side of the sensing unit 22 is connected with an elastic unit 25 , and the elastic unit 25 is used to adjust the distance between the nut and the screw 21 to ensure the closing pressure of the screw 21 on the switch 23 . The nut is a nut shell 24 with one end sealed. The sensing unit 22 is a photosensitive switch or a pressure sensitive switch.

[0055] The working process of this embodiment is: when the screw 21 is screwed into the nut shell 24, the screw 21 presses the switch 23, so that all the circuits inside the sensing unit 22 are disconnected and do no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com