Method for machining thermal western style suit

A processing method and technology of suits, applied in the field of suits, can solve the problems of bloated body, affecting the appearance of men, and poor warmth retention effect, etc., and achieve the effect of crisp and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

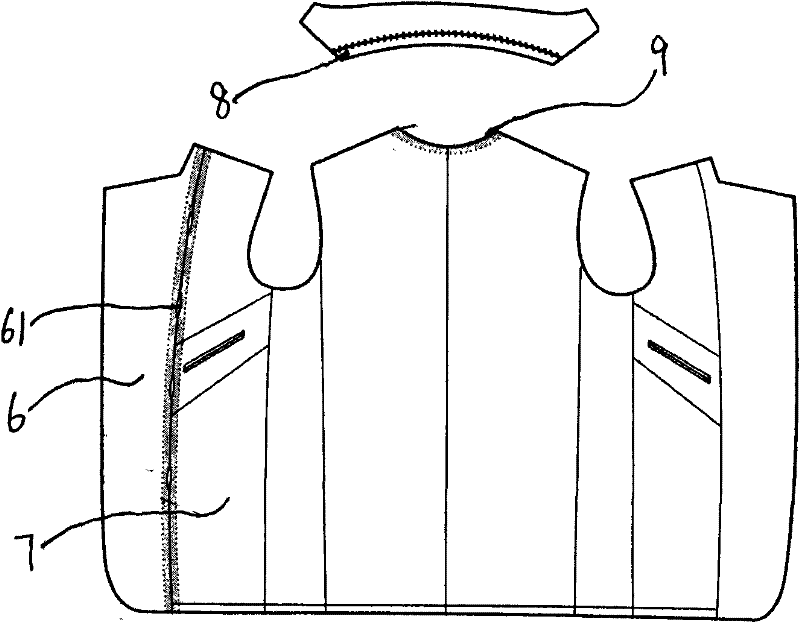

[0028] As shown in the figure, a kind of processing method of warm suit, it comprises the following steps:

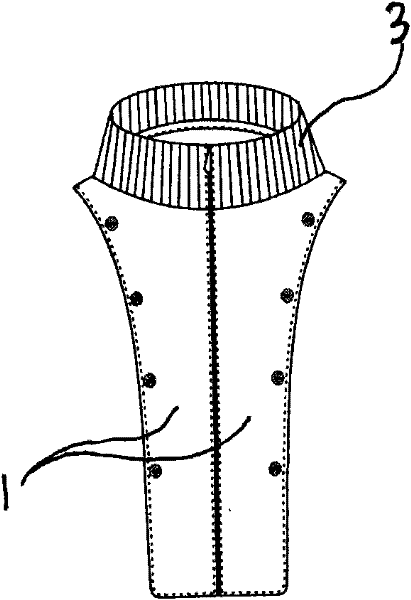

[0029] (1) Cut out two sets of inner tank left and right vermicelli 1 and inner tank back collar sticker 2 that meet the suit size design requirements, and stitch the inner tank rear collar sticker 2 with the inner tank left and right vermicelli 1 to form an inner tank. gut prototype;

[0030] (2), cut out a knitting collar 3 that matches the inner tank collar 11 of the inner tank prototype;

[0031] (3), the two sides of the knitted collar 3 are respectively stitched together with the inner tank collar 11 on a group of inner tank prototypes, so that the two sets of inner tank prototypes are respectively located on the upper and lower sides of the knitted collar 3;

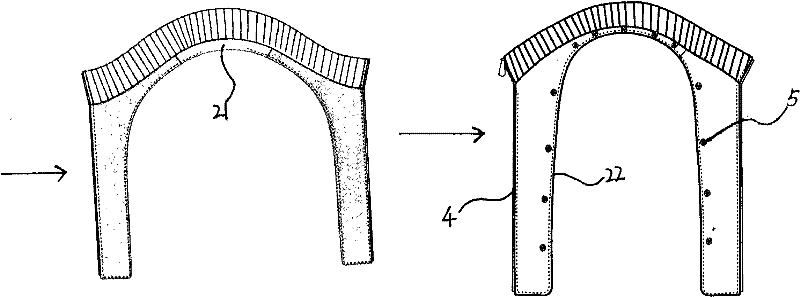

[0032] (4), the zipper 4 is respectively placed on the two outer edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com