Micropump

A technology of micro-pumps and valve membranes, which is applied to pumps, pump components, variable-capacity pump components, etc., which can solve the problems of unfavorable mass industrial production, and it is difficult to ensure that the input check valve and output check valve 15 are well closed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

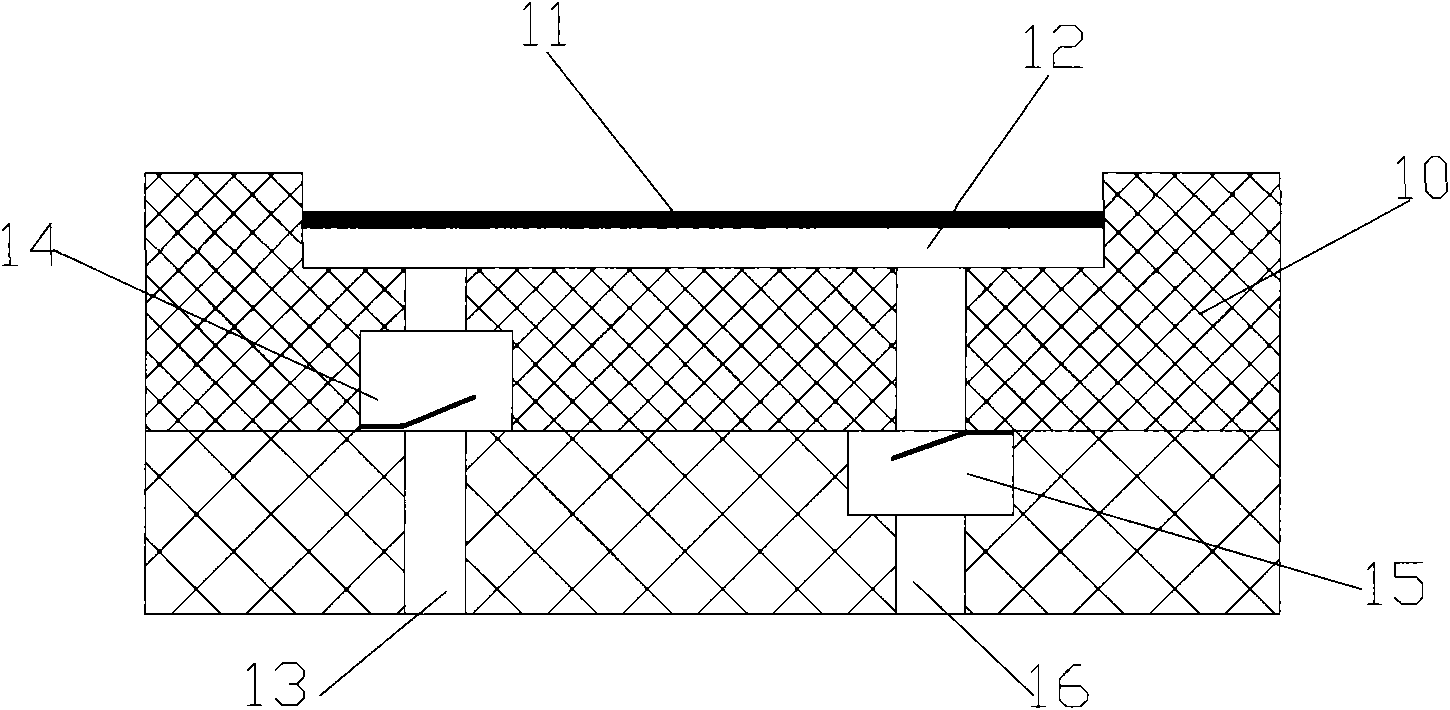

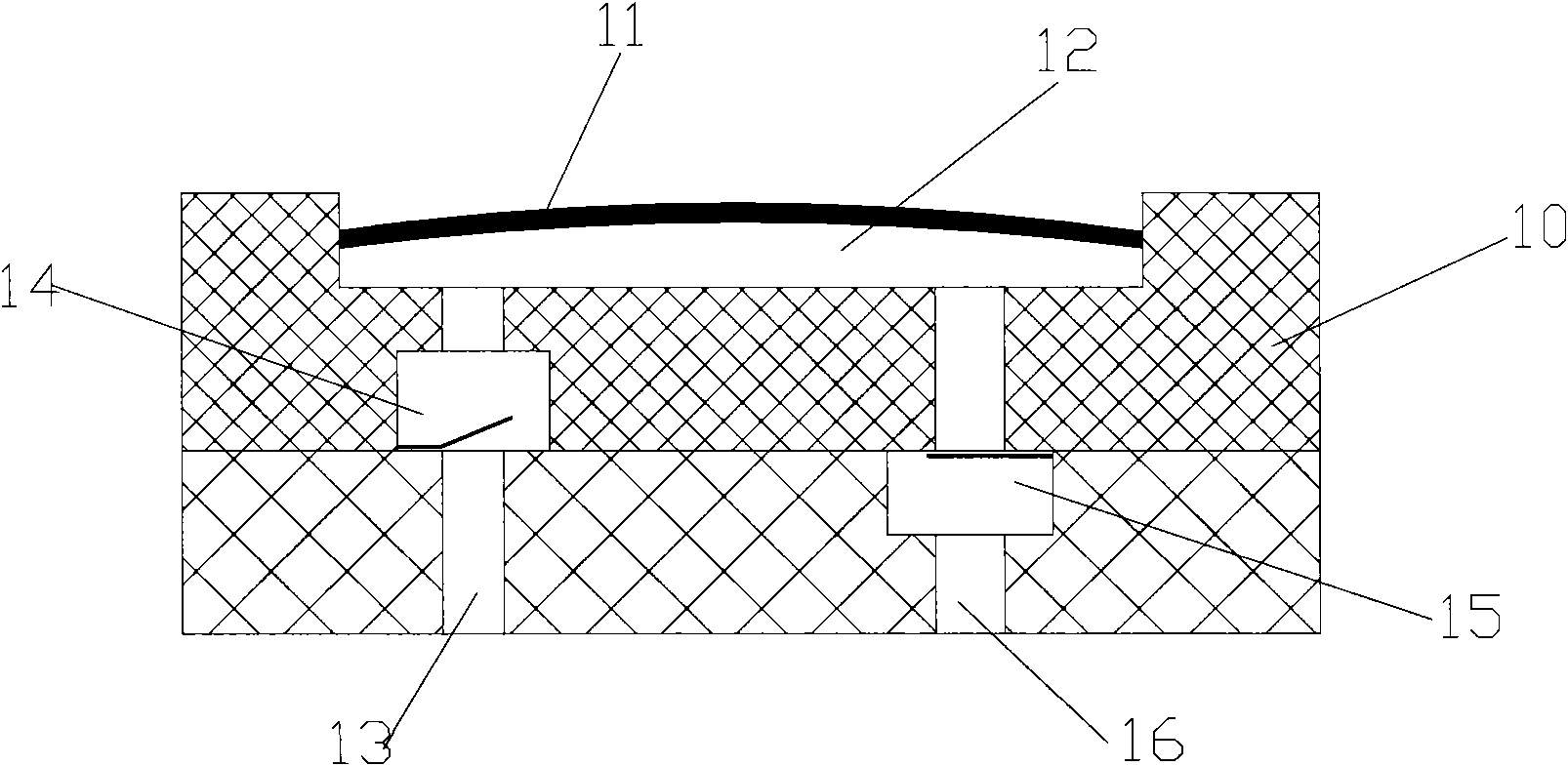

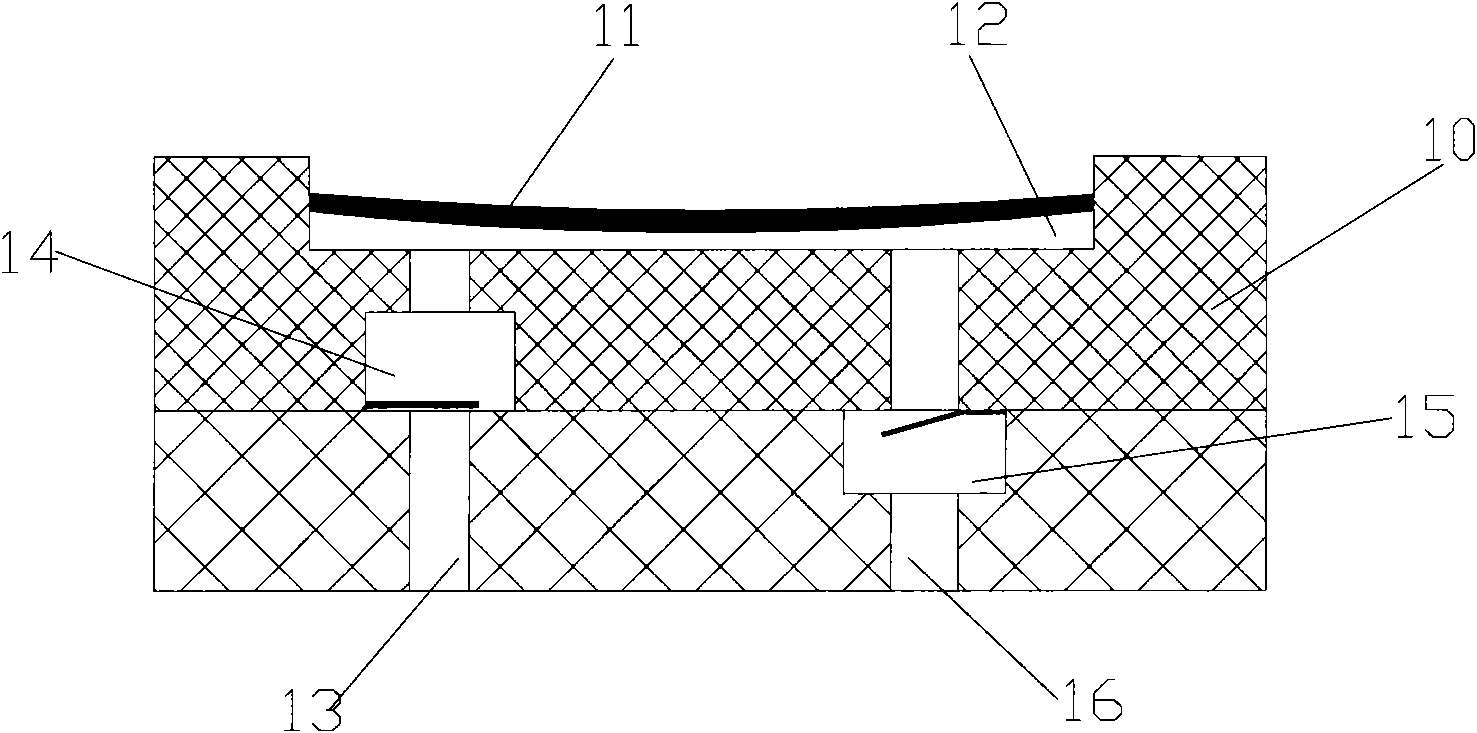

[0050] The invention provides a micropump for realizing reliable control of an input check valve and an output check valve.

[0051] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0052] see Figure 4 and Figure 5 , Figure 4 It is the structural diagram of the first embodiment of the micropump according to the present invention; Figure 5 for Figure 4 Sectional view A-A is shown.

[0053] The micropump described in the first embodiment of the present invention includes an actuating device, a space-variable cavity 2 , and an input channel and an output channel respectively connected to the space-variable cavity 2 . A valve membrane 7 that responds to the action of the actuating device is installed in the input channel and the output channel.

[0054] The micropump specifically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com