Backlight module

A backlight module and light technology, applied in optics, light guides, light sources, etc., can solve problems such as poor color saturation, unable to meet consumers' requirements for higher and higher color saturation of display devices, and improve color saturation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

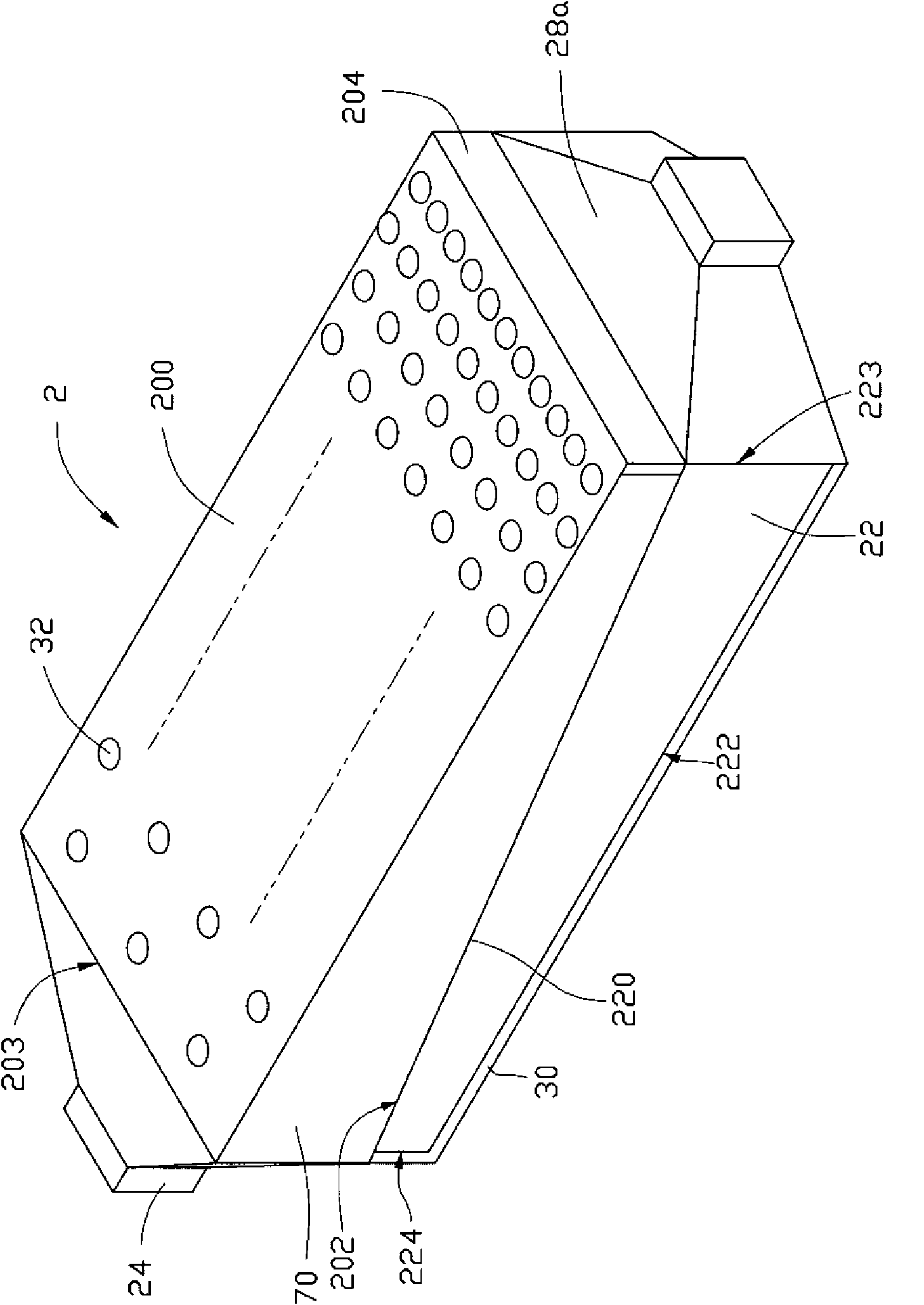

[0010] Such as figure 1 As shown, a backlight module 2 provided by the first embodiment of the present invention is provided. The backlight module 2 includes an upper light guide plate 20 and a lower light guide plate 22 stacked on each other. The upper light guide plate 20 includes a top surface 200 , a bottom surface 202 , a first end surface 203 and a second end surface 204 opposite to the first end surface 203 . The lower light guide plate 22 includes a top surface 220 , a bottom surface 222 , a third end surface 223 and a fourth end surface 224 opposite to the third end surface 223 . The top surface 200 of the upper light guide plate 20 is the light emitting surface of the backlight module 2 , and the bottom surface 222 of the lower light guide plate 22 is the reflective surface of the backlight module 2 . The bottom surface 202 of the upper light guide plate 20 and the top surface 220 of the lower light guide plate 22 are stacked on each other. The upper and lower lig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap