Self generating display and manufacturing method thereof

A manufacturing method, electrophoretic display technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as inconvenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

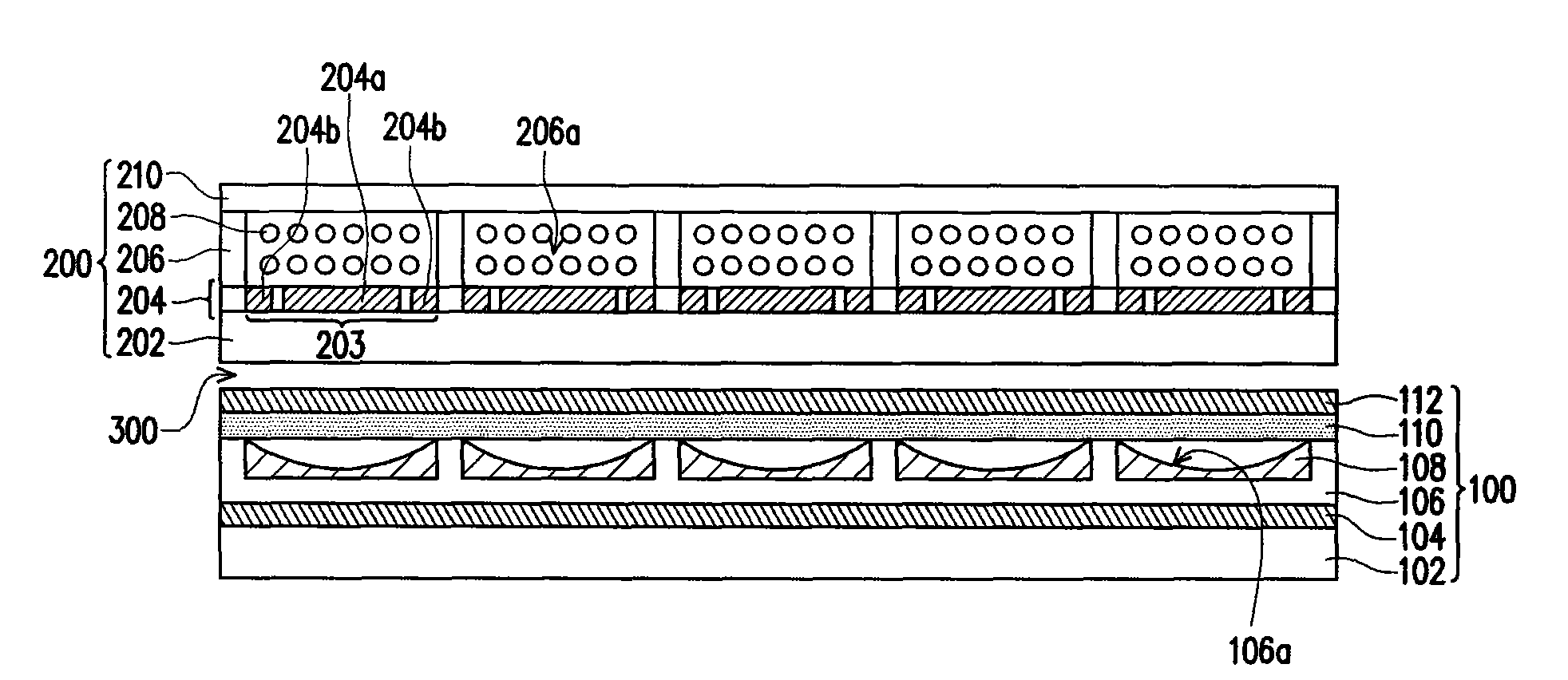

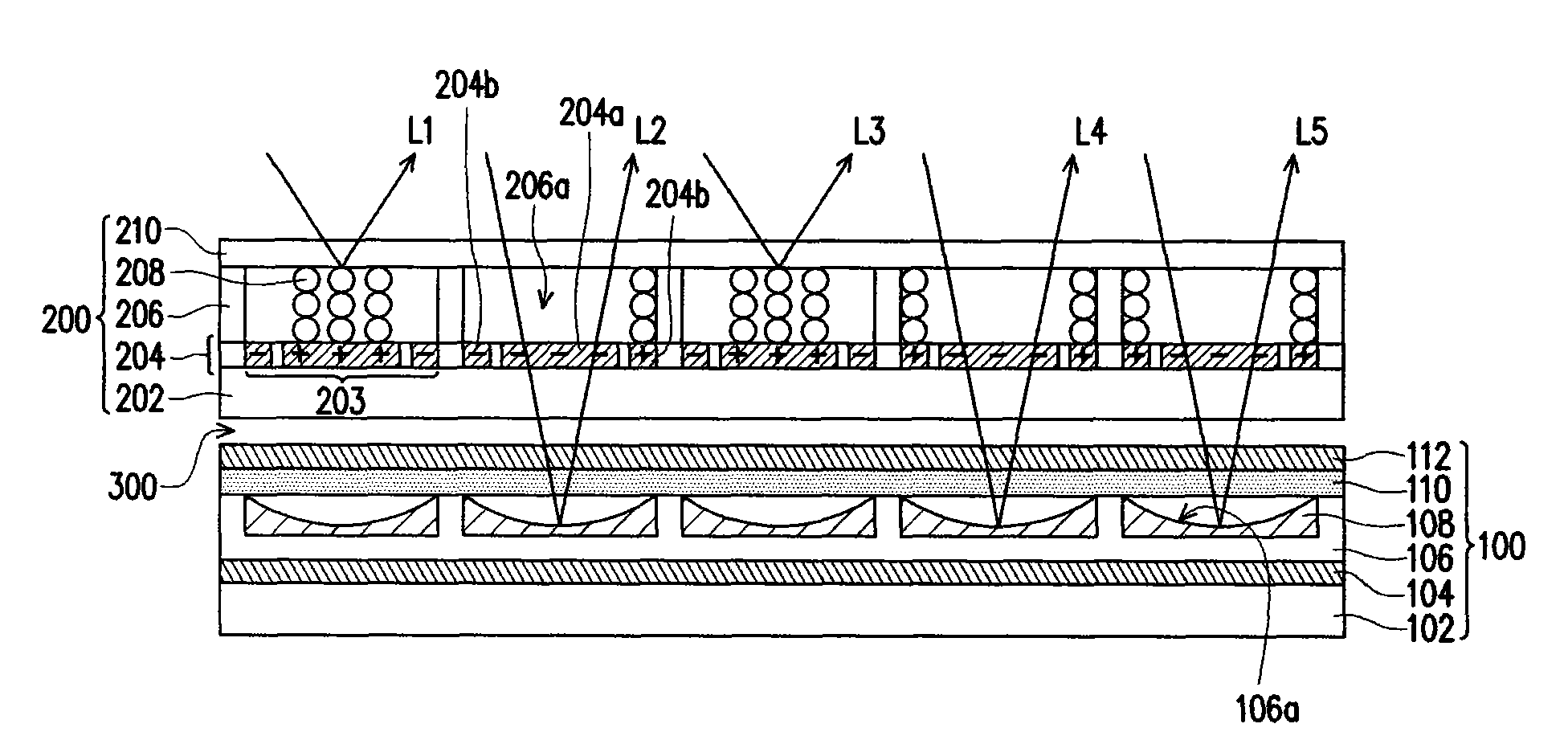

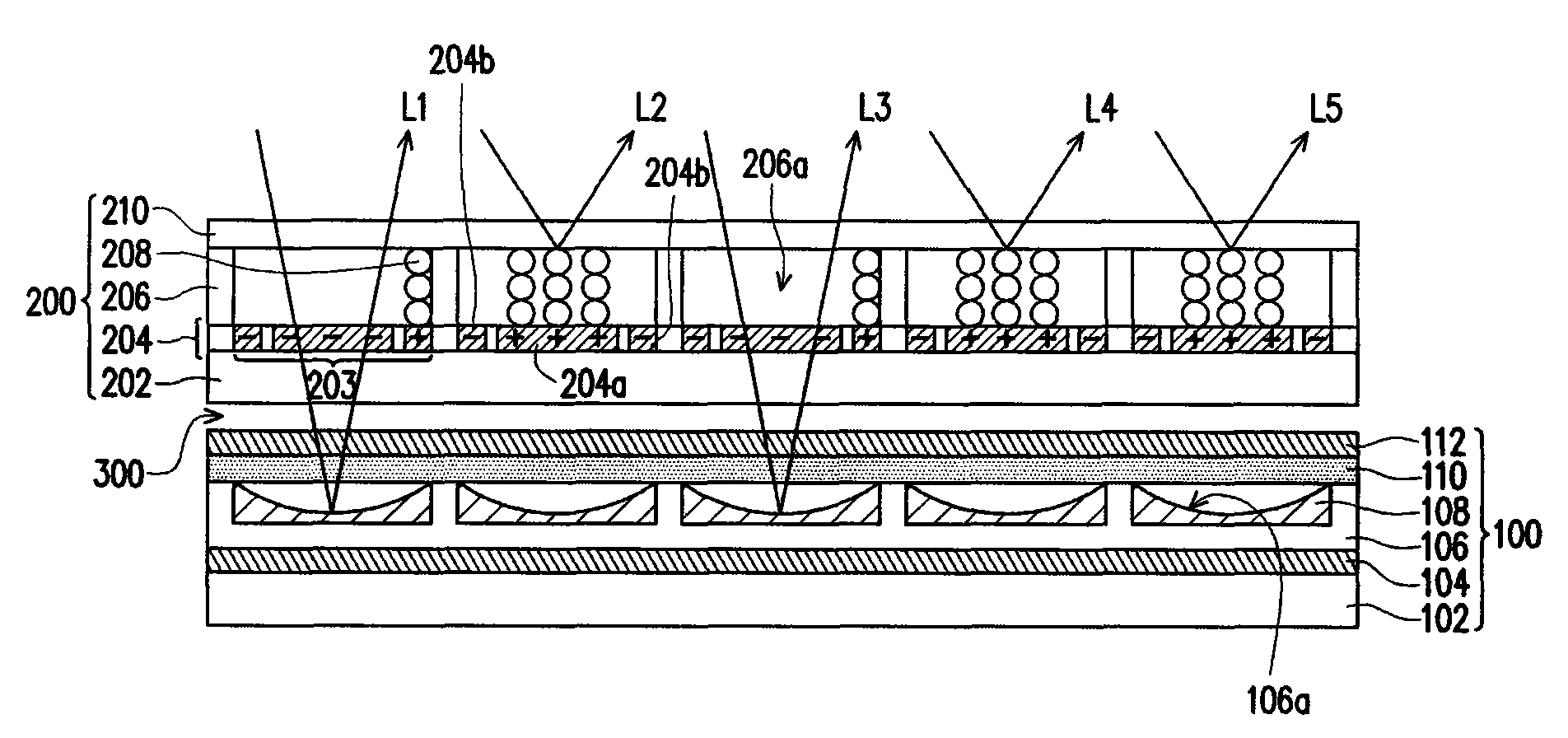

[0051] figure 1 It is a schematic cross-sectional view of a self-powered display according to an embodiment of the present invention. Please refer to figure 1 The self-powered display in this embodiment includes a dye-sensitized solar cell 100 and an electrophoretic display 200.

[0052] image 3 for figure 1 Schematic diagram of the dye-sensitized solar cell. Please also refer to figure 1 as well as image 3 The dye-sensitized solar cell 100 includes a first substrate 102, a lower electrode 104, a partition wall structure 106, a dye material 108, a solid electrolyte 110, and an upper electrode 112.

[0053] The first substrate 102 is mainly used to carry each layer of the dye-sensitized solar cell, and the first substrate 102 may be a rigid substrate or a soft substrate. To make the self-powered display of the present invention have flexible properties, the first substrate 102 needs to be a flexible substrate. Generally speaking, the material of the flexible substrate inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com