Automatic card sending machine

A technology of automatic card issuance and driving mechanism, which is applied to machines for issuing pre-printed tickets, computer components, auxiliary ticket issuing devices, etc., which can solve the problems of wasteful use of card capacity space, high machine cost, troublesome operation, etc., and reduce downtime The frequency of replacing the card storage mechanism, the low cost of the machine, and the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

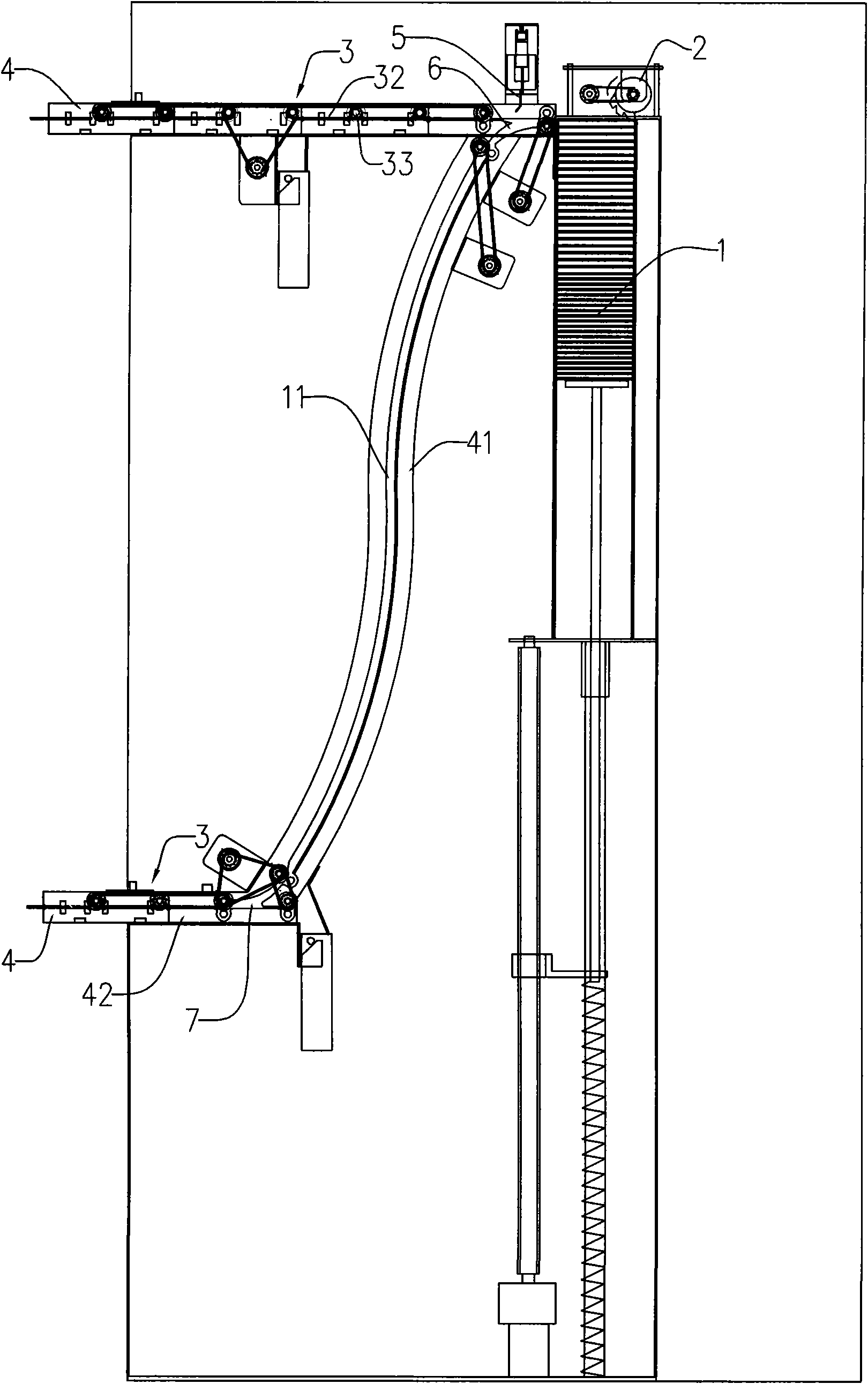

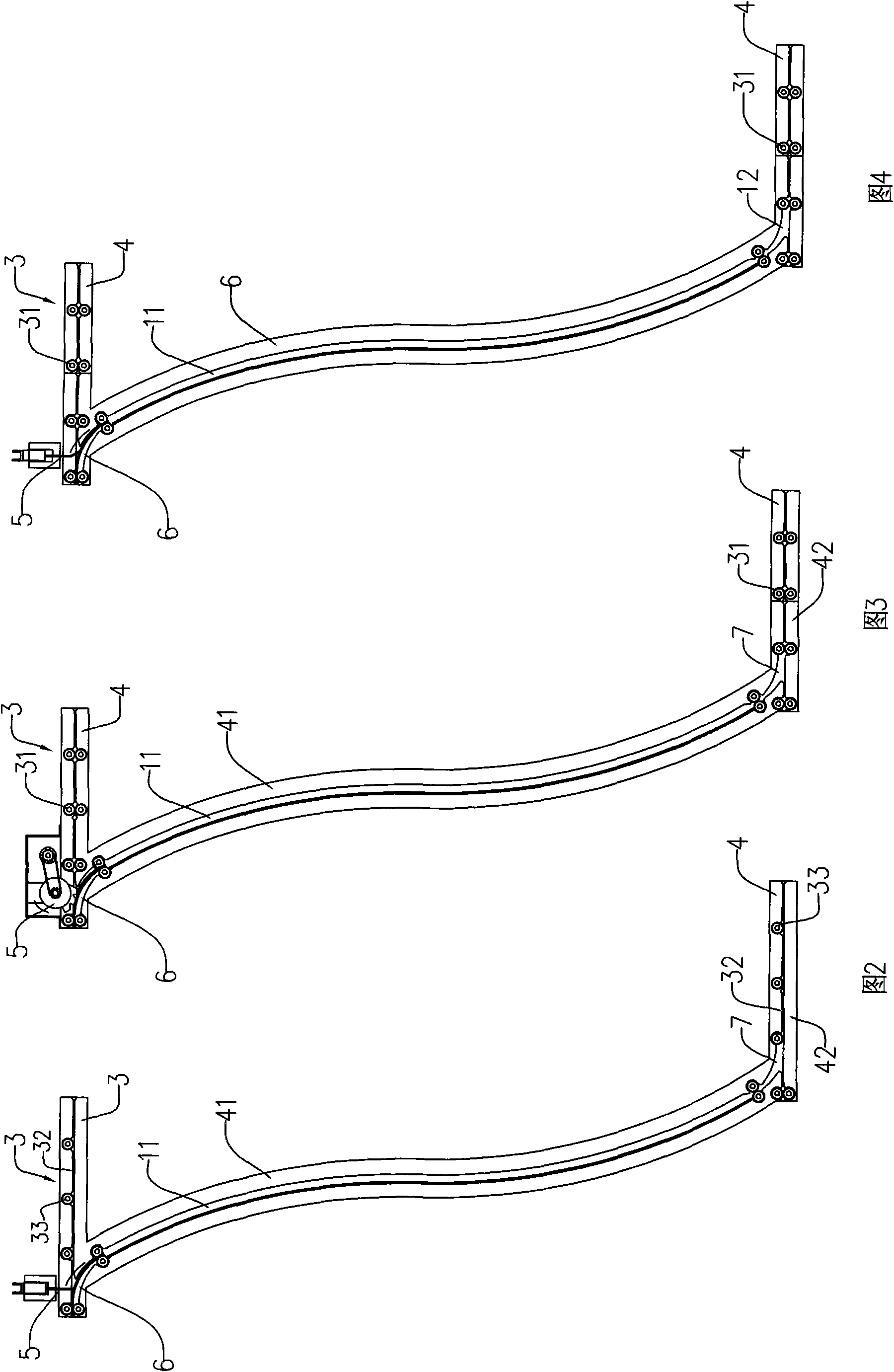

[0012] An automatic card issuing machine, such as figure 1 , including a card storage mechanism 1, a card dial mechanism 2 for pulling out cards in the card storage mechanism 1 one by one, a card delivery channel and a card delivery mechanism for sending out cards in the card delivery channel, and the card delivery channel is divided into upper and lower The lower two card-discharging channels 4 with different heights, the upper card-discharging channel and the lower card-discharging channel are all equipped with a card feeding mechanism 3 that sends out cards in the channel along the channel. The dialing mechanism 2 can be a friction wheel driven by a motor or a dial with convex teeth driven by a motor (such as figure 1 ) and other existing automatic card issuing machines. Described card feeding mechanism 3 can adopt the card feeding mechanism commonly used in the existing card issuing machine, for example: many pairs of rollers 31 that can be clamped and distributed at inte...

Embodiment 2

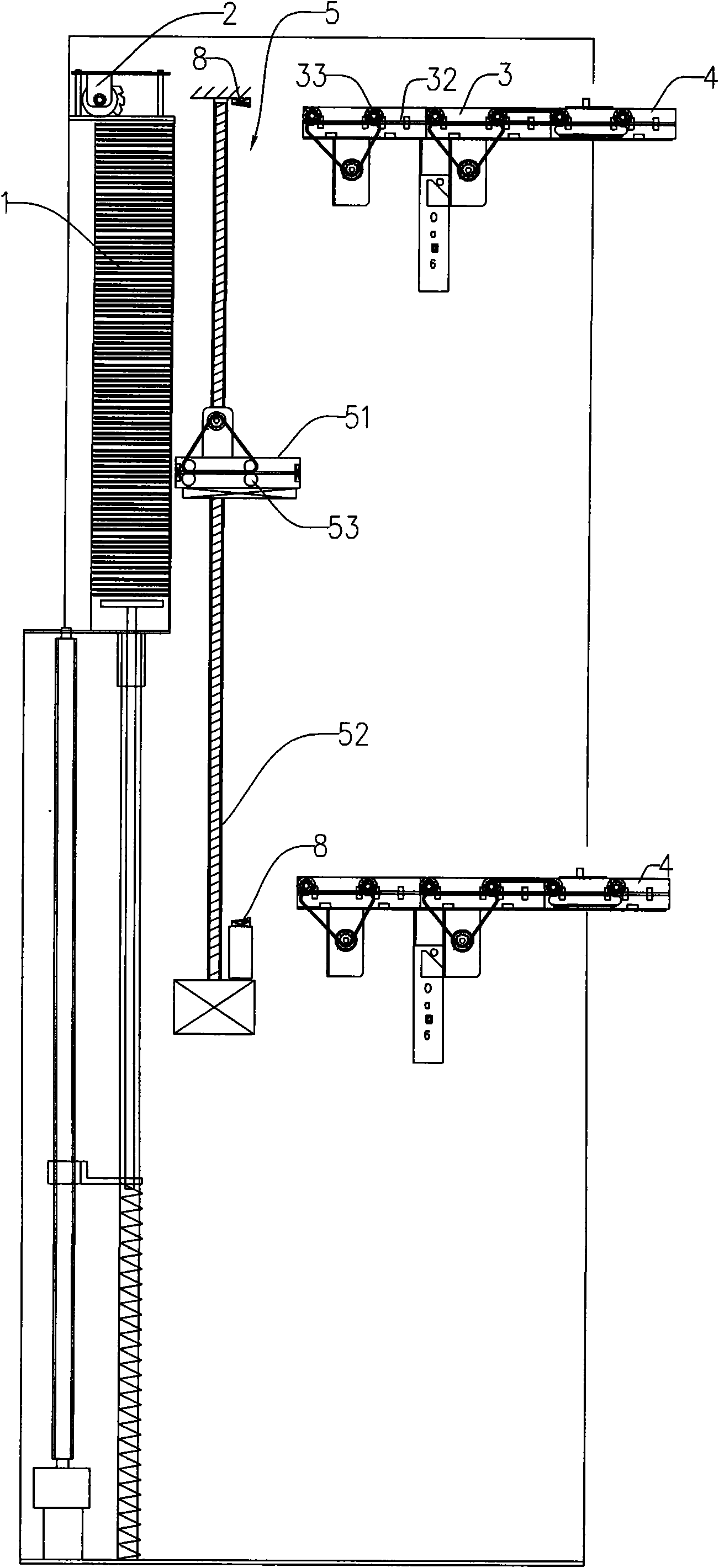

[0022] An automatic card issuing machine, such as Figure 5 , including a card storage mechanism 1, a card dial mechanism 2 for pulling out cards in the card storage mechanism one by one, a card guide mechanism 5, two upper and lower parallel card outlet channels 4 with different heights. The card guide mechanism includes a card transport mechanism 51, a drive mechanism 52 for driving the card transport mechanism to move up and down, and a card delivery mechanism 53 installed on the card transport mechanism for transporting cards. The driving mechanism 52 is a screw mandrel driven by a motor, and the card transport mechanism 51 is mounted on the screw mandrel by a nut matched with the screw mandrel. When the motor drives the screw mandrel to rotate, the card transport mechanism moves up and down along the screw mandrel. The rear end of the card transport mechanism 51 is flush with the front end of each card output channel 4 . The card feeding mechanism 53 can be a pair of rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com