Manual assembly method of virtual three-dimensional model based on VRML-JAVA

An assembly method and virtual three-dimensional technology, applied in the field of part model assembly, can solve the problems of weak sense of reality, inability to realize manual movement, and weak human-computer interaction function, so as to improve the sense of reality, enhance the sense of reality, and improve the design efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

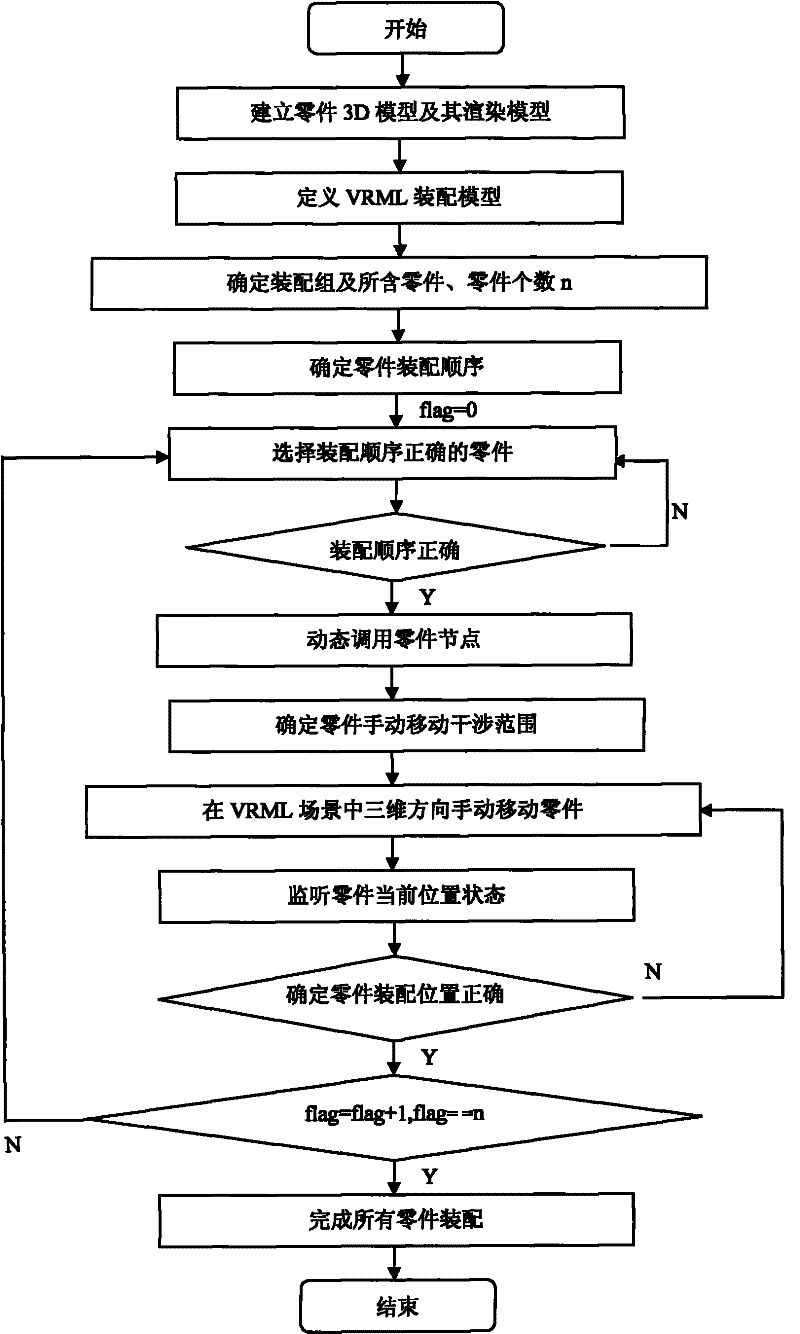

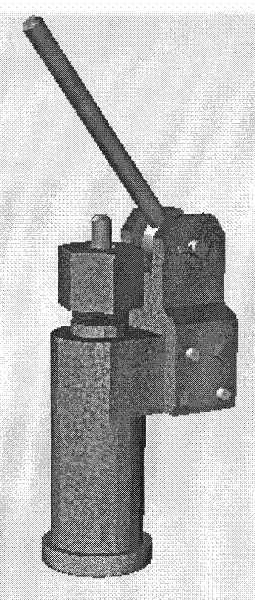

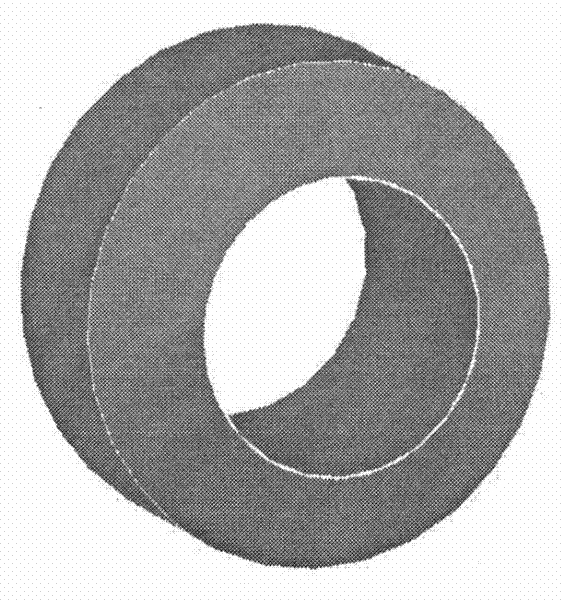

[0093] The present invention will be further described below with reference to the accompanying drawings and in conjunction with the specific manual assembly of the hand pressure valve. There are 15 parts that need to be manually assembled for this hand pressure valve. According to the assembly sequence, they are spring seat, spring, valve stem, packing, packing gland, gland nut, bracket, screw 1, pin 1, screw 2, pin 2 , sockets, small shafts, cotter pins and handles. The following takes the packing, packing gland and gland nut as examples to illustrate the manual assembly of the virtual 3D model.

[0094] Such as figure 1 A manual assembly method of a virtual three-dimensional model of a hand pressure valve is shown, and the steps are as follows:

[0095] 1) Establish the 3D model and rendering model of the hand pressure valve parts.

[0096] According to the actual size of the hand pressure valve, establish the 3D model and assembly model of each part of the hand pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com