Liquid level detector

A liquid level detector and electrolyte technology, which is applied to the liquid level indicator of physical variable measurement, electrolysis process, electrolysis components, etc. Avoid misleading probes, simple structure and low manufacturing cost

Inactive Publication Date: 2011-01-05

南京容宇能源科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, hydrogen and oxygen generators work by electrolyzing water. The electrolysis equipment basically adopts the form of an electrolytic cell to electrolyze water to produce hydrogen and oxygen gas. During the electrolysis process, it is necessary to monitor the depth of the electrolyte in the electrolyte tank in real time. Too much electrolyte will cause the electrolysis to fail to proceed normally, or even malfunction. When the electrolyte in the liquid tank is working, the internal liquid and gas mixture is in a state of boiling, and the above-mentioned liquid level detection equipment cannot normally detect the actual depth of the electrolyte in the electrolyte tank

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

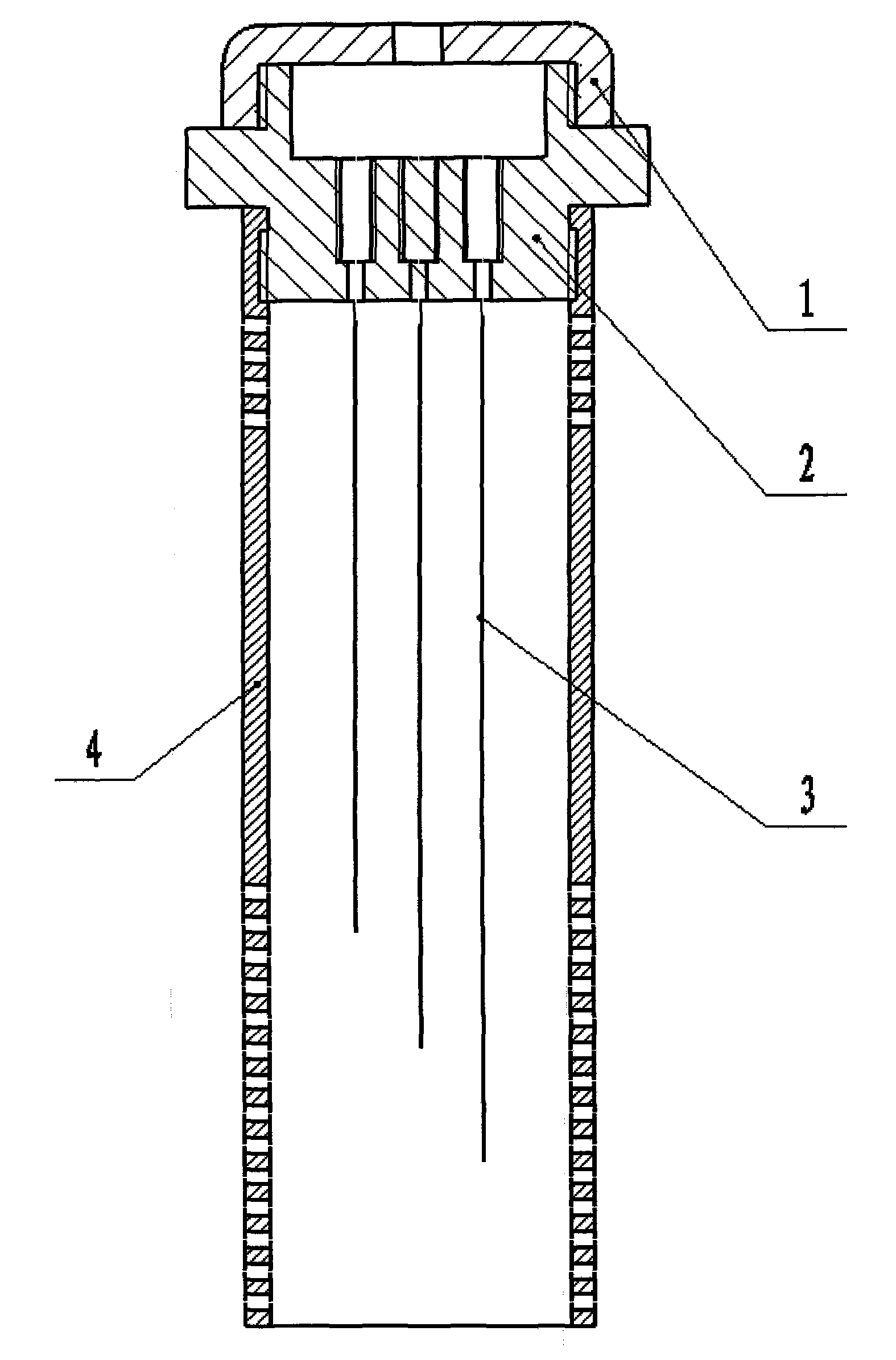

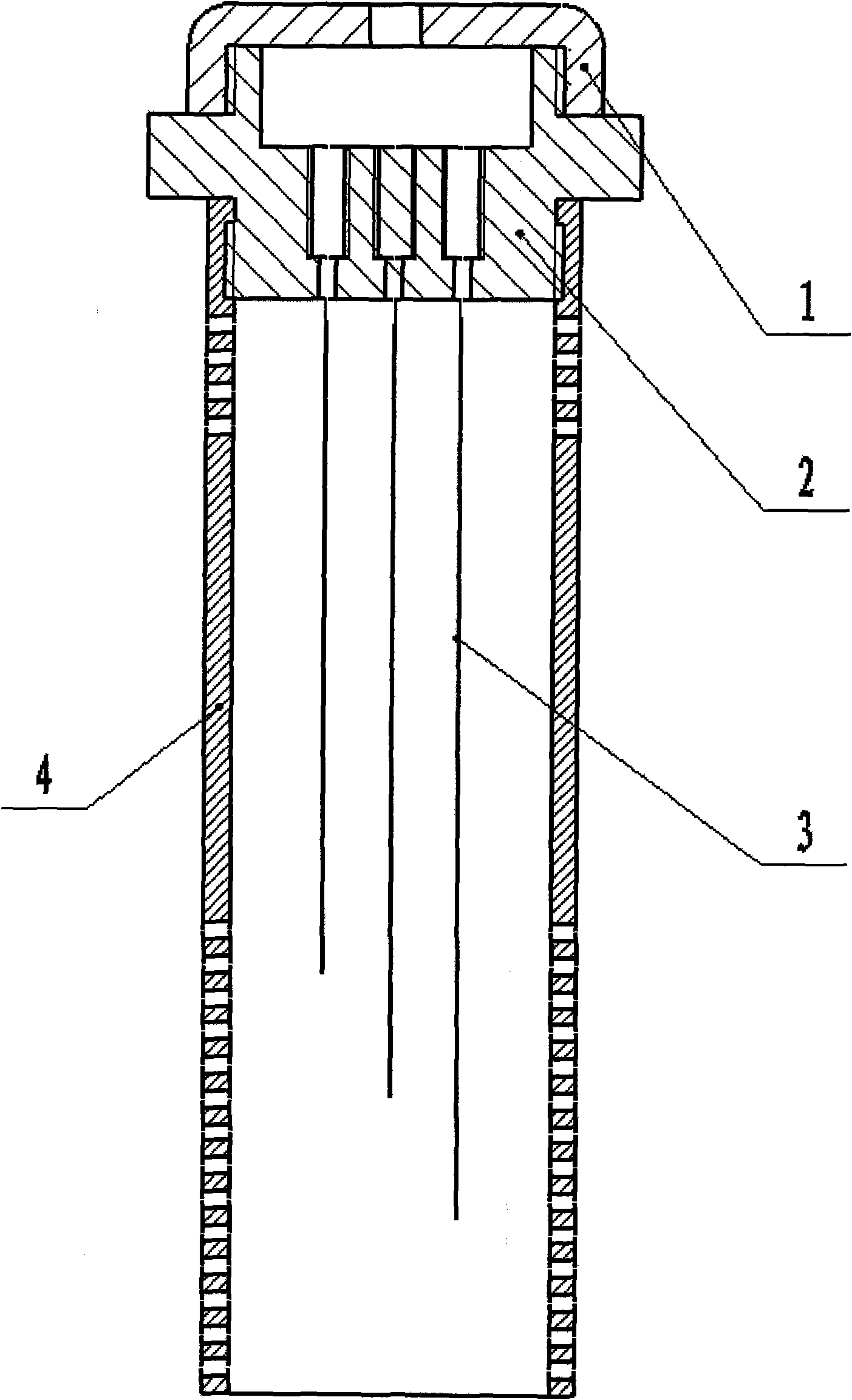

The invention provides a liquid level detector which comprises a nut cap, a nut, a long probe, a middle probe, a short probe and a spattering prevention sleeve. Peripheral equipment comprises an electrolyte tank, electrolyte, an electric wire and a control circuit. The spattering prevention sleeve is in a cover-free cylindrical structure, threads are arranged on the inner wall of the opening position at the upper end, and both the circumference of the lower part of the threads and the circumference of the lower part of the spattering prevention sleeve are provided with more than one row of uniformly distributed small holes; both the upper end and the lower end of the nut are provided with threads, the middle part of the nut is provided with a step, and the middle part of the step is provided with a counter bore; three small through holes are arranged in the counter bore; a through hole is arranged in the middle of the nut cap; the long probe, the middle probe and the short probe are sequentially installed in the three small holes of the nut; the lower end of the nut is matched and screwed with the spattering prevention sleeve, and the upper end of the nut is matched with the nut cap; the three probes are respectively connected with the electric wire; the electric wire is connected with the control circuit by the through hole in the nut cap; and the liquid level detector is installed in the electrolyte tank with the electrolyte. The invention solves the problem of detection accuracy of a traditional liquid level detector and has the characteristics of low manufacture cost, simple structure, and the like.

Description

a liquid level detector Technical field: The invention relates to a liquid level detector and belongs to the field of electrolyzed water devices. Background technique: At present, hydrogen and oxygen generators work by electrolyzing water. The electrolysis equipment basically adopts the form of an electrolytic cell to electrolyze water to produce hydrogen and oxygen gas. During the electrolysis process, it is necessary to monitor the depth of the electrolyte in the electrolyte tank in real time. Too much electrolyte will cause the electrolysis to fail normally, or even malfunction. Too little electrolyte will lead to insufficient gas production. When the electrolyte in the liquid tank is working, the internal liquid and gas mixture is in a state of approximate boiling, and the above-mentioned liquid level detection equipment cannot normally detect the actual depth of the electrolyte in the electrolyte tank. Invention content: The invention provides a liquid level detec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01F23/22C25B15/00C25B1/04

CPCY02E60/366Y02E60/36

Inventor 吕新民杜海涛王晓尉陈姚建平

Owner 南京容宇能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com