Electronic packaging method and device

An electronic and packaging technology, applied in circuits, electrical components, transportation and packaging, etc., can solve problems such as insurmountable substrate warpage and transmission problems in the size of the working area, limiting production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

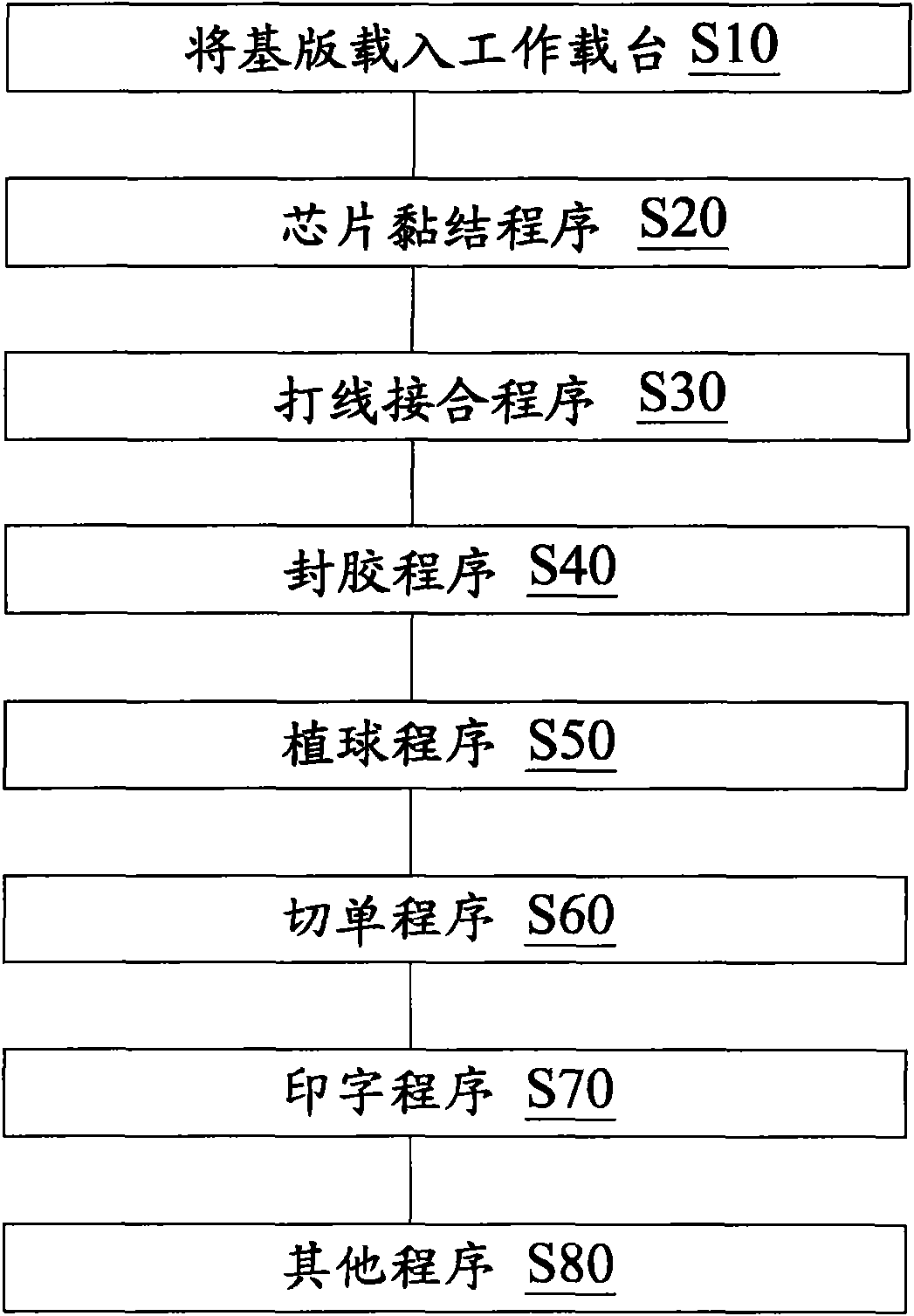

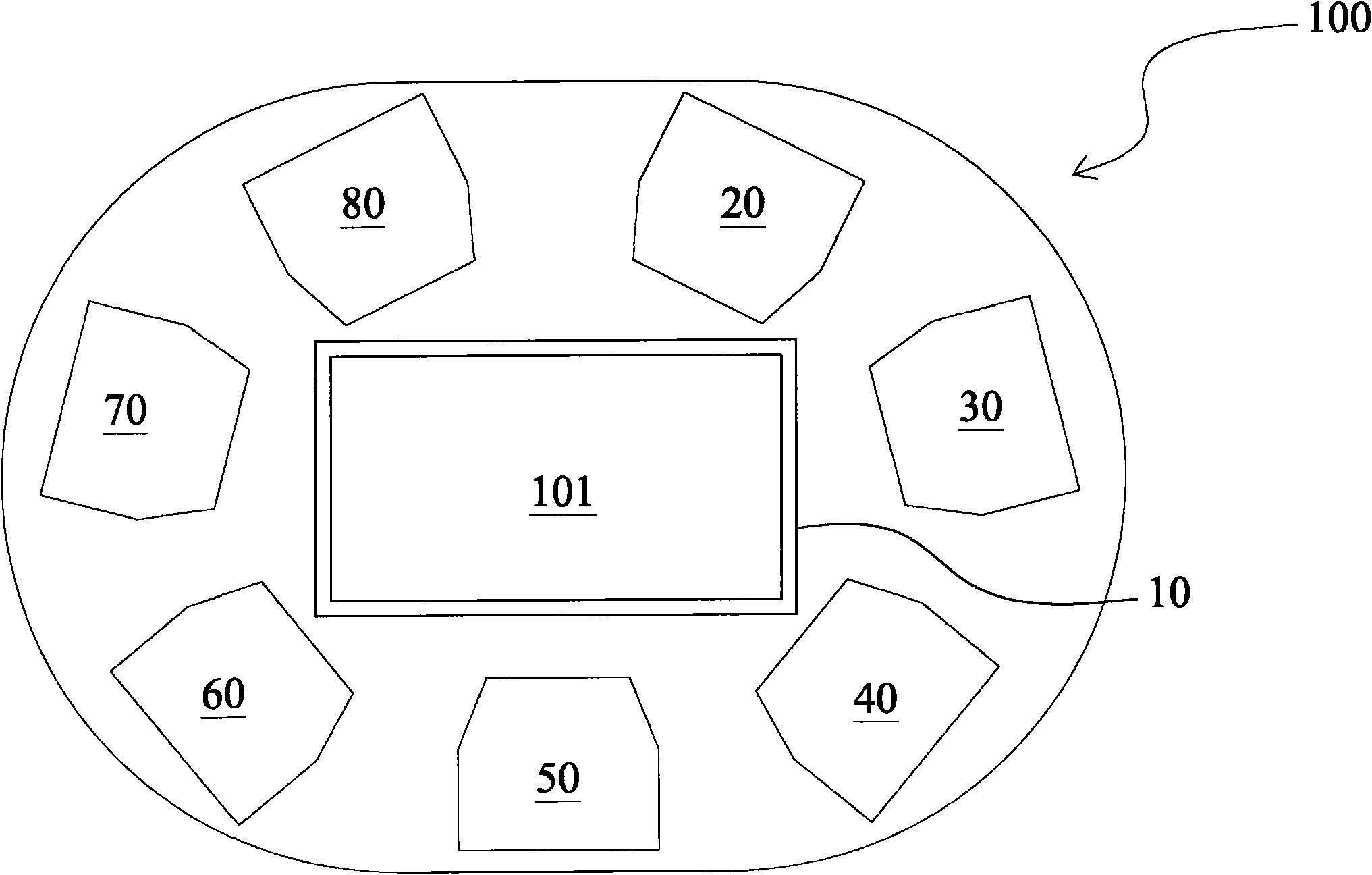

[0010] figure 1 Shown is a schematic flowchart of an electronic assembly method according to an embodiment of the present invention. In this embodiment, firstly, a substrate is loaded on the work platform ( S10 ). Wherein, the substrate can be a full version substrate (panel substrate). Next, a die attach procedure (die attach) is performed to fix a plurality of chips on the substrate (S20). Wherein, the die bonding process is to move a die bonding device, such as a glue dispensing device, a chip grabbing device, etc., to the work platform for operation. Afterwards, a wire bonding process (wire bond) is performed to electrically connect the chip to the substrate by using a plurality of wires ( S30 ). Wherein, the wire bonding procedure is to move a wire bonding device to the work platform for operation.

[0011] Next, a molding process (mold) is performed to cover the chip and the leads ( S40 ). Among them, the sealing procedure is to move the sealing device to the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com