Pneumatic tire

一种充气轮胎、轮胎周向的技术,应用在重型轮胎、轮胎零部件、轮胎胎面/胎面花纹等方向,能够解决轮胎低滚动阻力性等问题,达到减小滚动阻力、保持滚动阻力、提高抗偏磨耗性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

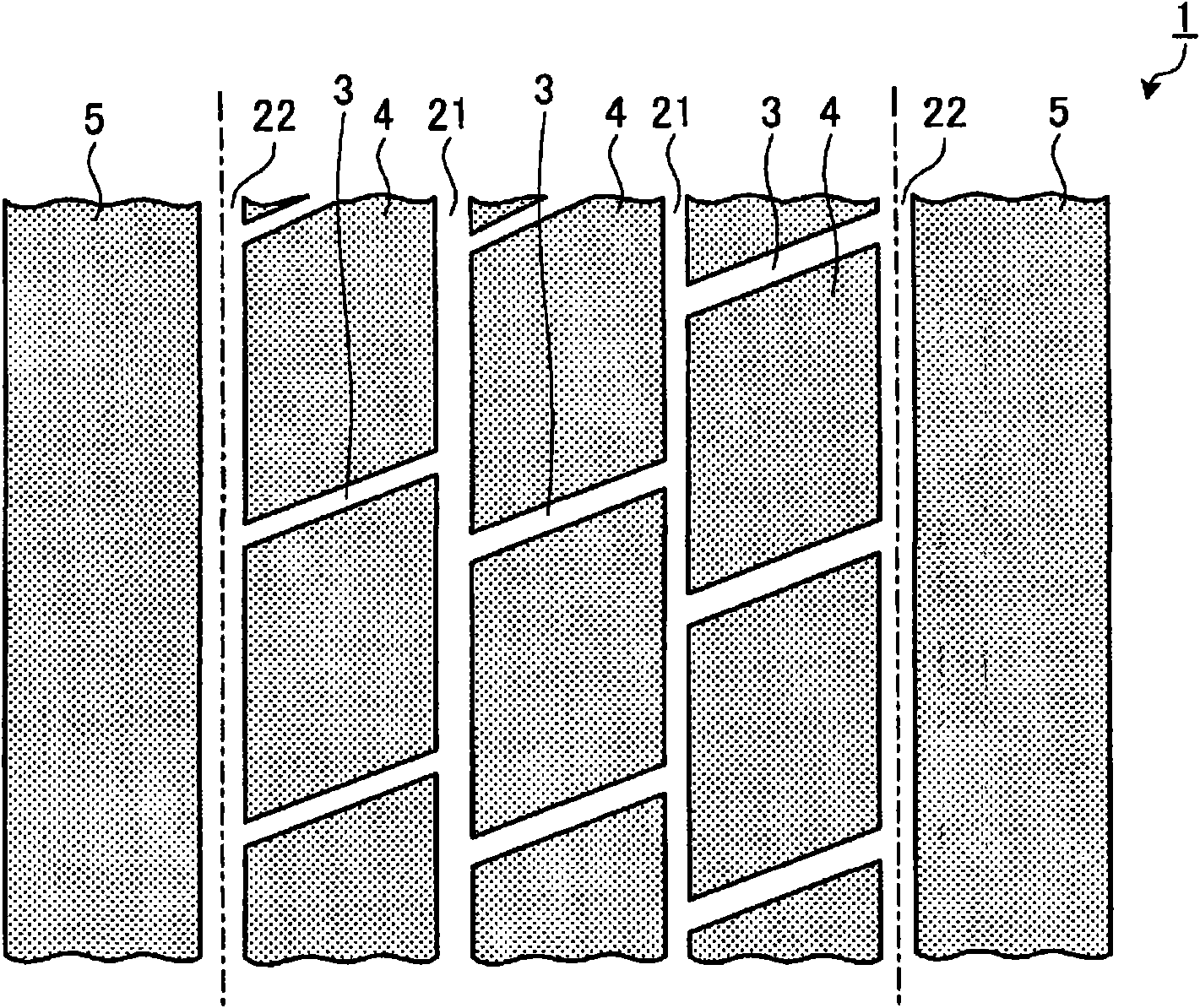

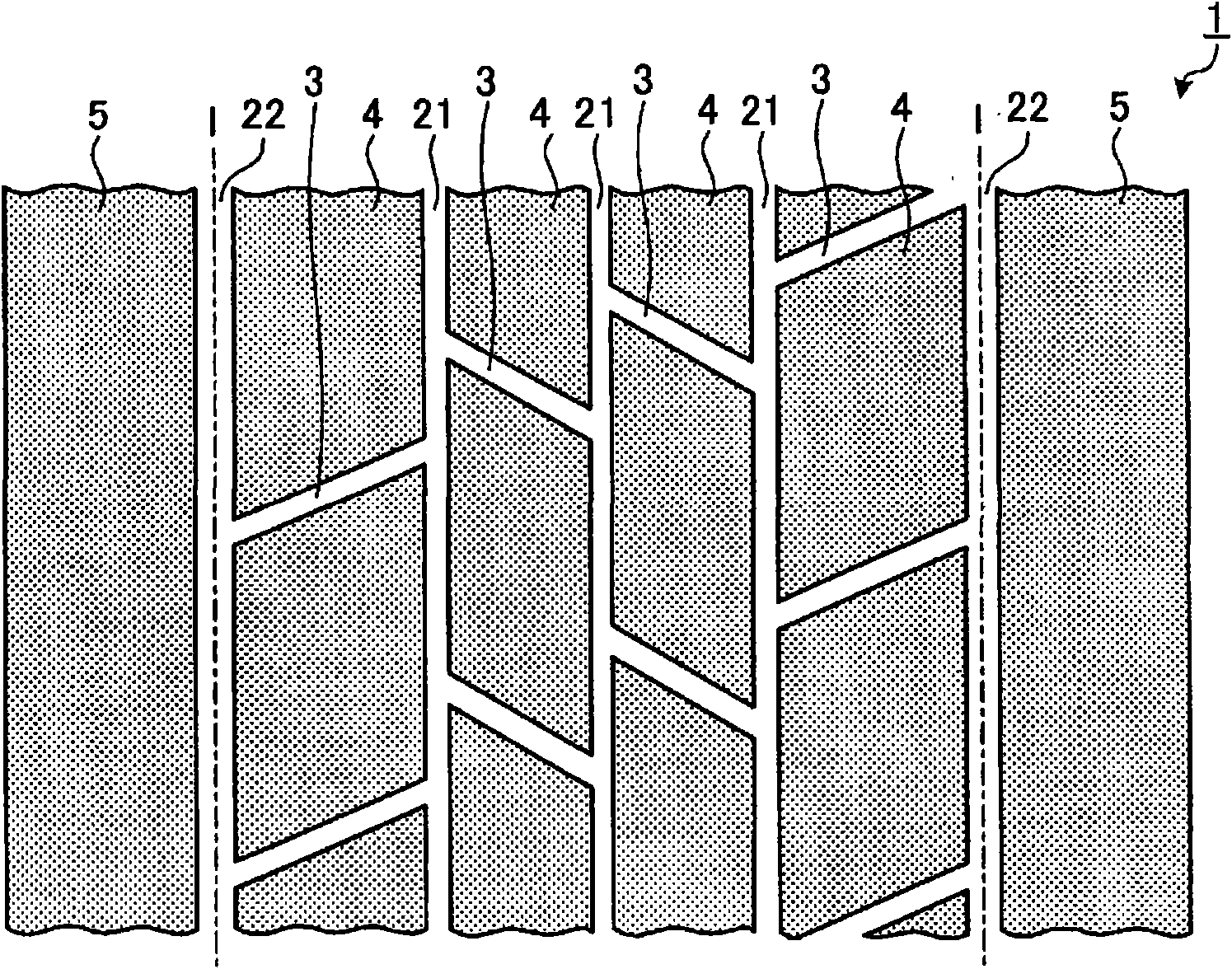

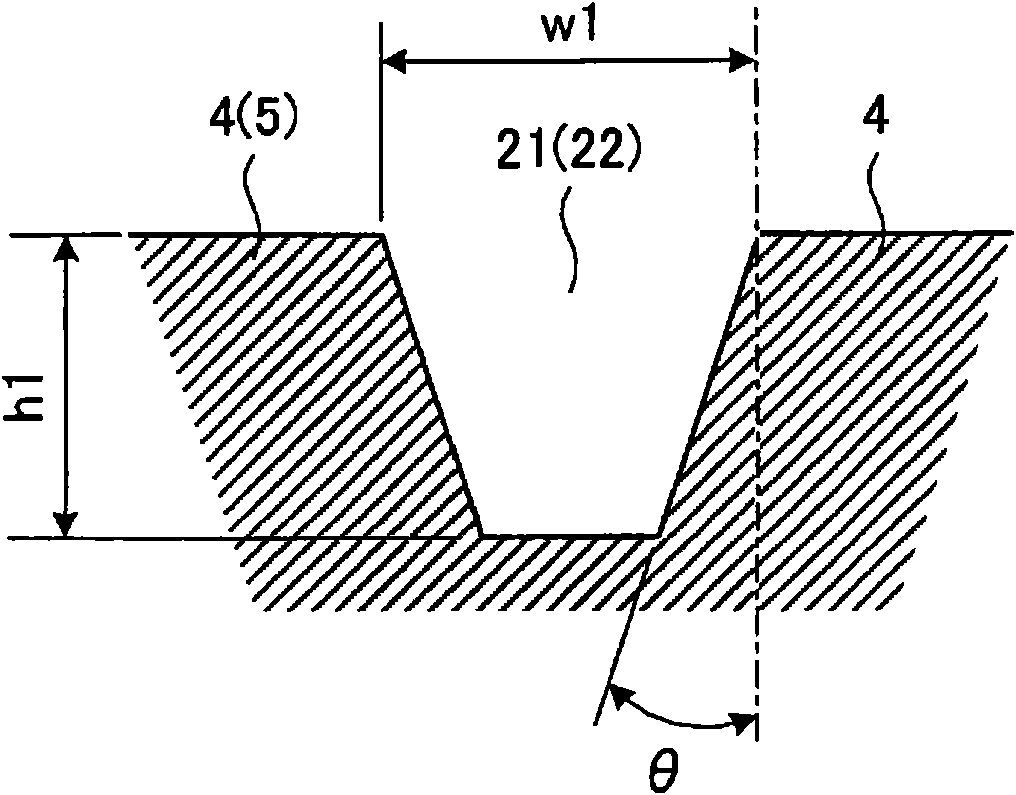

[0046] figure 1 is a top view of a tread of a pneumatic tire according to an embodiment of the present invention. Figure 2-6 yes figure 1 A schematic diagram of a modified version of the pneumatic tire shown. Figure 7 is a result table of the performance test of the pneumatic tire according to the embodiment of the present invention.

[0047]In the pneumatic tire 1, a traction pattern is formed on the tread portion, including: three or more circumferential main grooves 21, 22 extending in the tire circumferential direction; a plurality of widthwise grooves 3 extending in the tire width direction; and a plurality of rows The land portions 4 , 5 defined by the circumferential main grooves 21 , 22 and the widthwise groove 3 . The centerline I of the outermost circumferential main groove 22 in the tire width direction serves as a boundary line at which the tread portion is divided into a center region and a shoulder region. The shoulder area is the area from the center line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com