Plastic bottle making machine integrating pouring and blowing

A bottle making machine and concentrated injection technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of low production efficiency, achieve the effect of improving production efficiency and solving low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

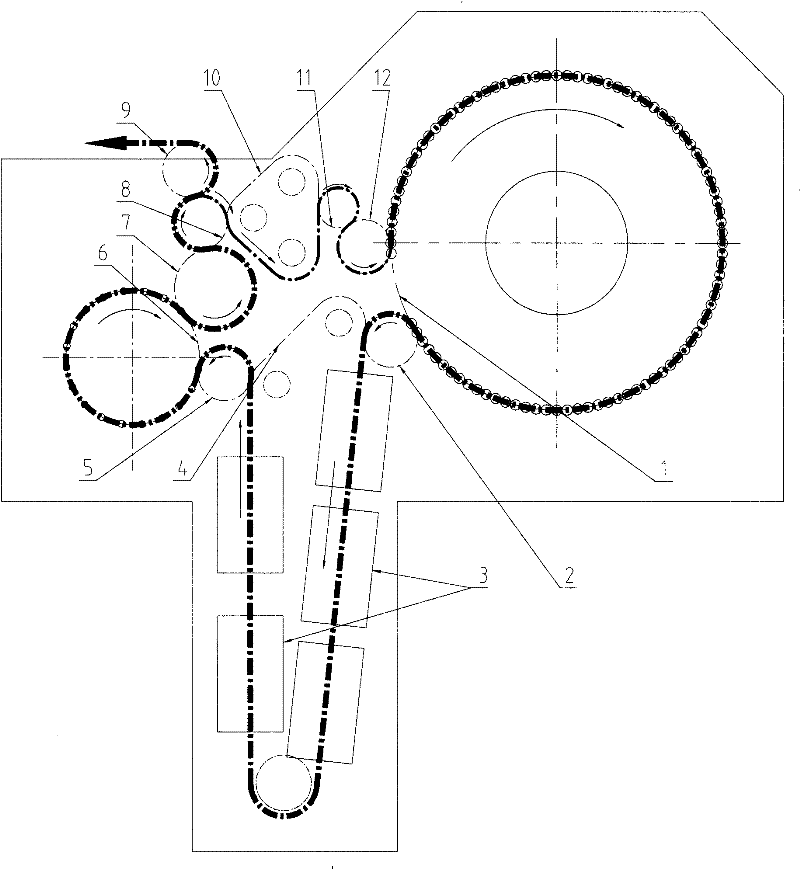

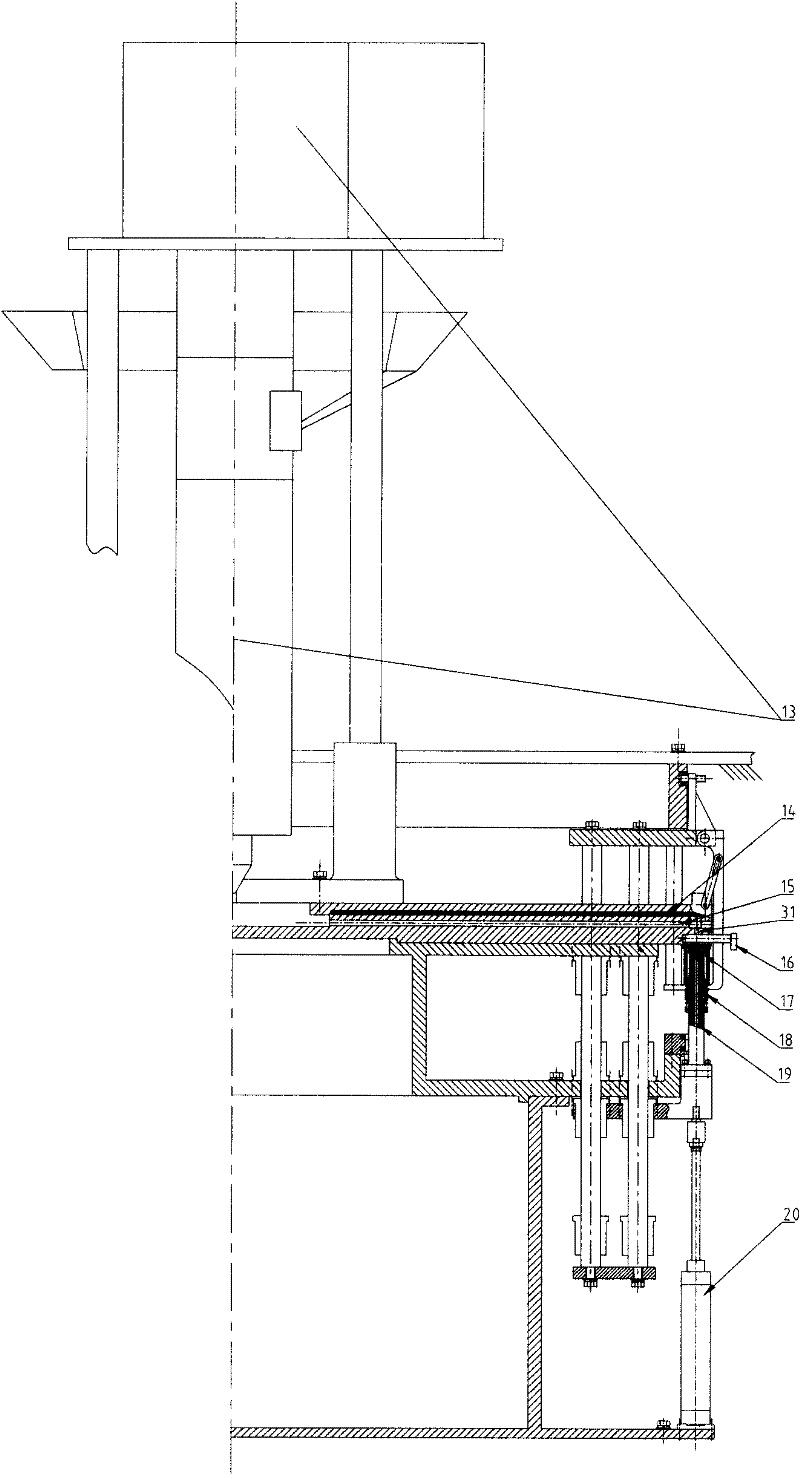

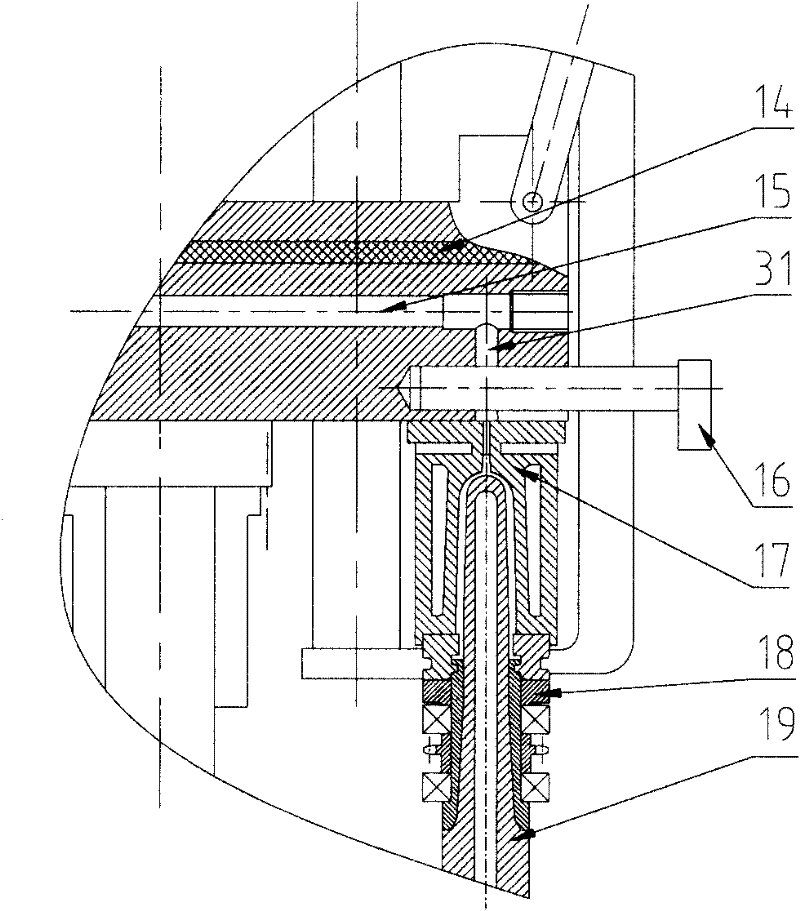

[0025] figure 1 It shows the technological process and working schematic diagram of the plastic bottle making machine integrating preform injection and bottle blowing. Such as figure 1 As shown, in an embodiment of the present invention, a plastic bottle-making machine integrating preform injection and bottle blowing is provided, which includes: a preform-making system 1 for manufacturing preforms 23; The preform system 1 is connected to output the preforms 23; the heating conveyor chain 4 is connected to the preform turntable 2 and used to transfer the preforms 23; the heating furnace 3 is used to heat the preforms 23 Conveyor chain 4 is sent to heating furnace 3 places, and wherein, heating furnace 3 can be set to any suitable number, for example, can be set to a plurality of as required, also can be one; Blowing system 6, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com