Hyperbranched polymer and preparation method and application thereof

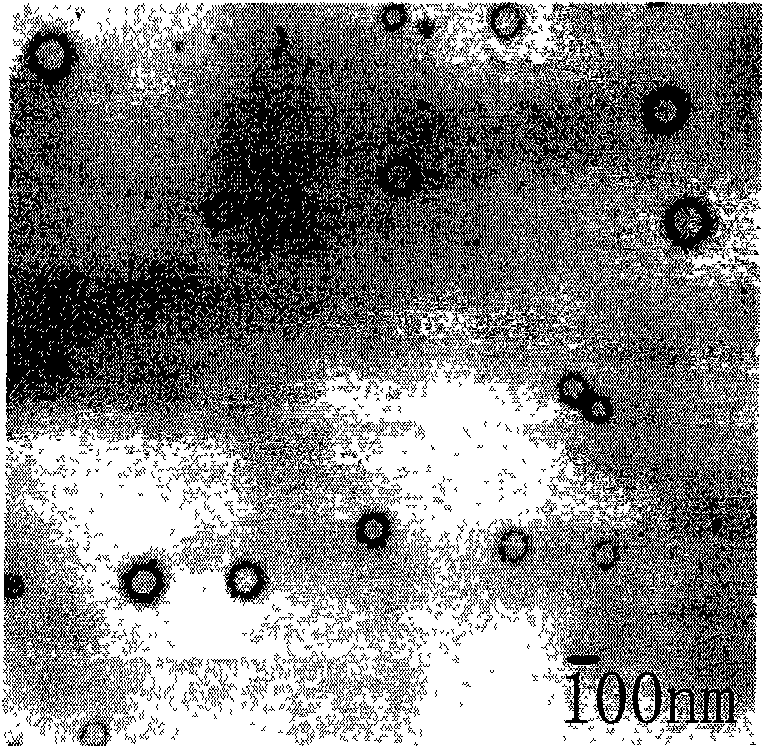

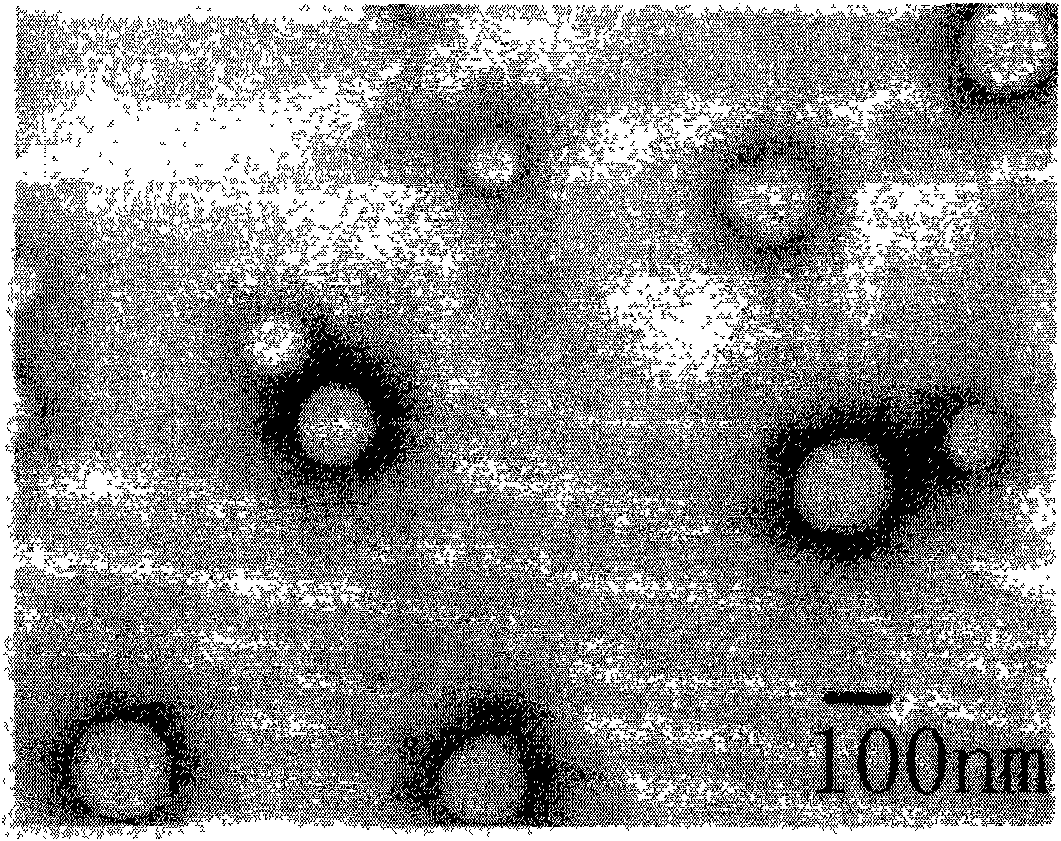

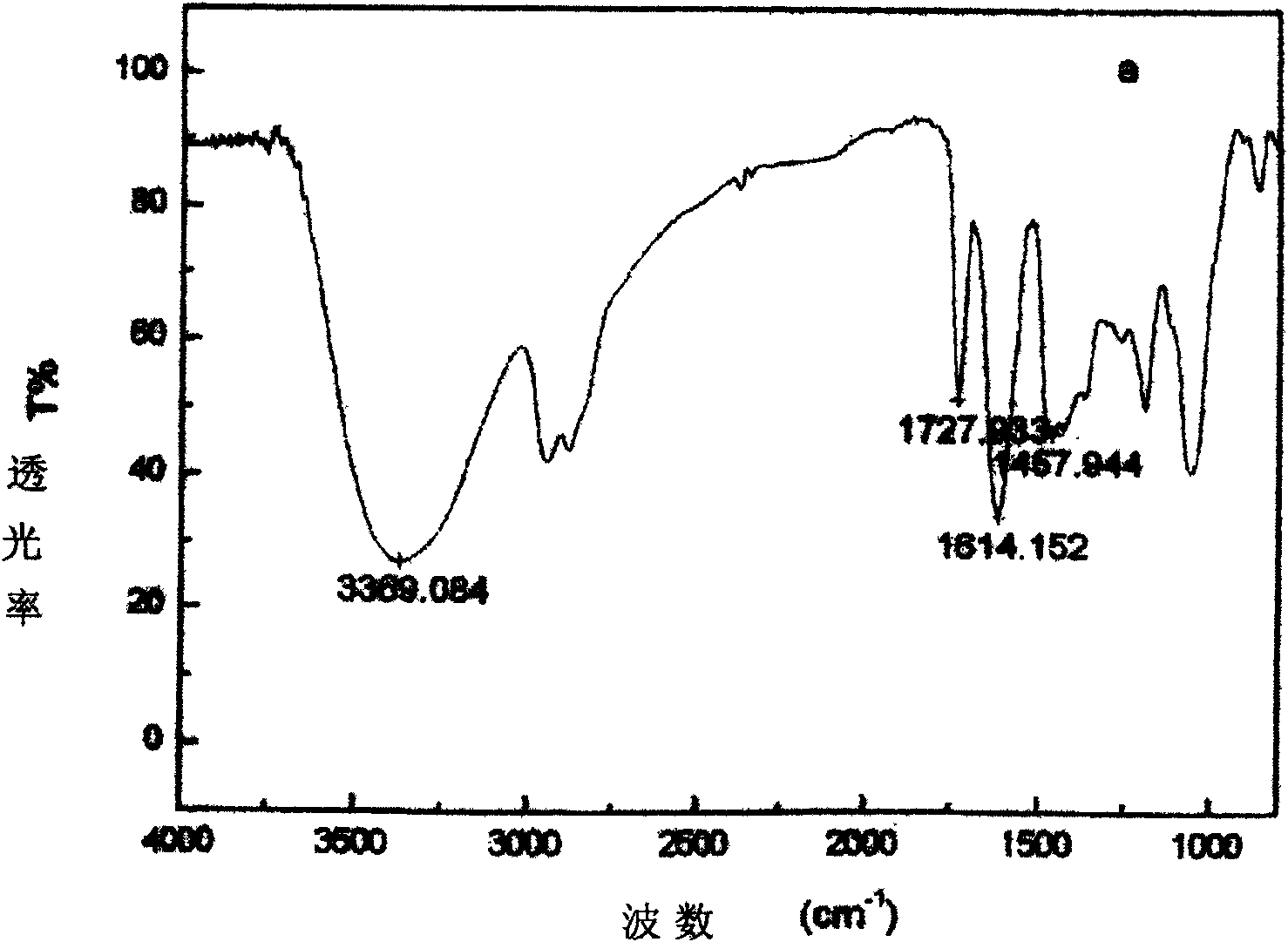

A technology of hyperbranched polymers and hyperbranched polyurethanes, applied in the field of nanomaterials, can solve problems such as narrow molecular weight distribution of hyperbranched polyurethanes, inability to use as drug carriers, and inability to form micelles, etc., to improve bioavailability and biological activity, Wide applicability, improving the effect of drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of hyperbranched polyurethane

[0046] A. Preparation of N, N-dihydroxyethyl-3-aminomethyl acrylate monomer

[0047] Add 8.609g methyl acrylate, 10.514g diethanolamine and 10ml methanol mixture in the there-necked flask, at room temperature and logical N 2 Stir for 30 minutes under normal conditions, then heat up to 40 ° C for 4 hours, and then remove excess methyl acrylate and methanol through vacuum distillation to obtain a colorless and transparent oily liquid, namely, N, N-dihydroxyethyl-3-amino Methyl acrylate monomer.

[0048] B. Preparation of the second generation hyperbranched polyurethane polymer

[0049] Add 1.342g 1,1,1-trimethylolpropane, 5.93g N,N-dihydroxyethyl-3-aminomethyl acrylate monomer and 0.017g tetraisobutoxytitanium in the there-necked flask as catalyst , the reaction system at N 2 Under protection, the reaction was carried out at a constant temperature of 120°C for 12 hours to obtain a yellow viscous liquid. Dissolve the crud...

Embodiment 2

[0058] 1. Preparation of hyperbranched polyurethane

[0059] A. Preparation of N, N-dihydroxyethyl-3-aminomethyl acrylate monomer

[0060] In the there-necked flask, add 8.609g methyl acrylate, 10.514g diethanolamine and 10ml methanol, the mixture is at room temperature and logical N 2 Under normal circumstances, stir for 30 minutes, then heat up to 40 ° C for 4 hours, and then remove excess methyl acrylate and methanol through vacuum distillation to obtain a colorless and transparent oily liquid N, N-dihydroxyethyl-3-aminomethacrylate ester monomer.

[0061] B. Preparation of the second generation hyperbranched polyurethane

[0062] Add 1.342g 1,1,1-trimethylolpropane, 15.93g N,N-dihydroxyethyl-3-aminomethyl acrylate monomer and 0.017g tetraisobutoxytitanium in the three-necked flask as catalyst , the reaction system at N 2 Under protection, the reaction was carried out at a constant temperature of 120°C for 12 hours to obtain a yellow viscous liquid. Dissolve the crude ...

Embodiment 3

[0068] 1. Preparation of hyperbranched polyurethane

[0069] A. Preparation of N, N-dihydroxyethyl-3-aminomethyl acrylate monomer

[0070] Add 8.609g methyl acrylate, 10.514g diethanolamine and 10ml methanol mixture in the there-necked flask, at room temperature and logical N 2 Under normal circumstances, stir for 30 minutes, then raise the temperature to 40 ° C for 4 hours, and then remove excess methyl acrylate and methanol through vacuum distillation to obtain a colorless and transparent oily liquid N, N-dihydroxyethyl-3-aminoacrylic acid Methyl ester monomer.

[0071] B. Preparation of the second generation hyperbranched polyurethane polymer

[0072] Add 1.342g 1,1,1-trimethylolpropane, 15.93g N,N-dihydroxyethyl-3-aminomethyl acrylate monomer and 0.017g tetraisobutoxytitanium in the three-necked flask as catalyst , should be system in N 2 Under protection, the reaction was carried out at a constant temperature of 120°C for 12 hours to obtain a yellow viscous liquid. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Critical micelle concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com