Stranding machine lapping device

A stranding machine and wrapping technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of increased cost, many processes, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

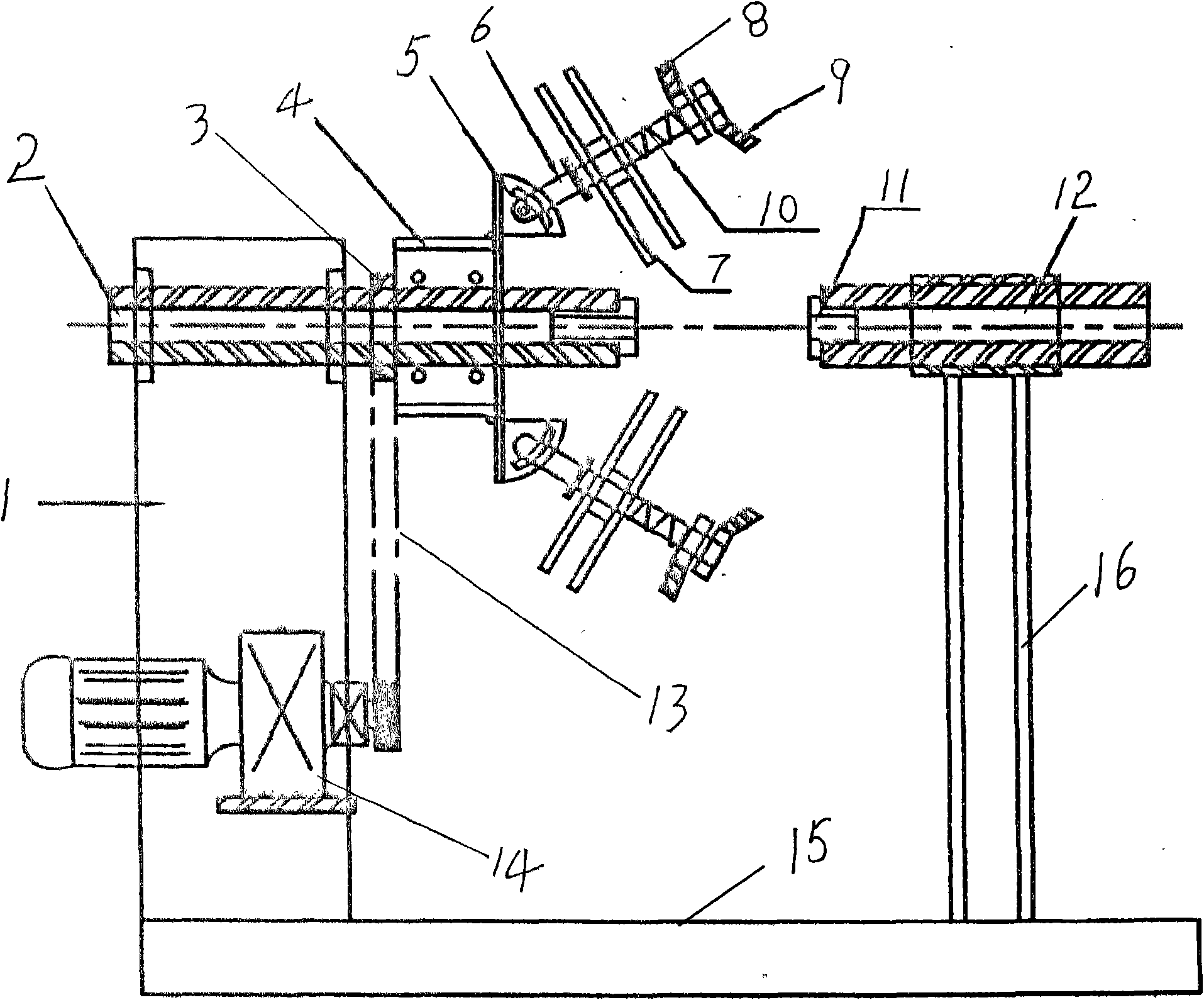

[0006] Embodiments are described in detail with reference to the accompanying drawings. In the present invention, a strip-shaped base 15 is installed between the wire outlet of the stranding machine and the traction wheel, a chassis 1 is installed upwards at the front end of the base 15, a pair of columns 16 are installed upwards at the rear end, and a steplessly variable speed slide is installed at the lower part of the chassis. Differential motor 14, the upper end is equipped with a protruding forward wire pipe 2, and a rear wire pipe 12 is installed on a straight line with a distance from the front of the front wire pipe coaxial line on the column. A transmission wheel 3 is fixed on the box body, and a transmission belt 13 is arranged on the transmission wheel to be connected with the driving wheel of the motor. A wrapping head 4 is coaxially fixed on the rear side of the transmission wheel 3 on the front wire pipe 2 of the stranding machine. Two wrapping shafts 6 are symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com