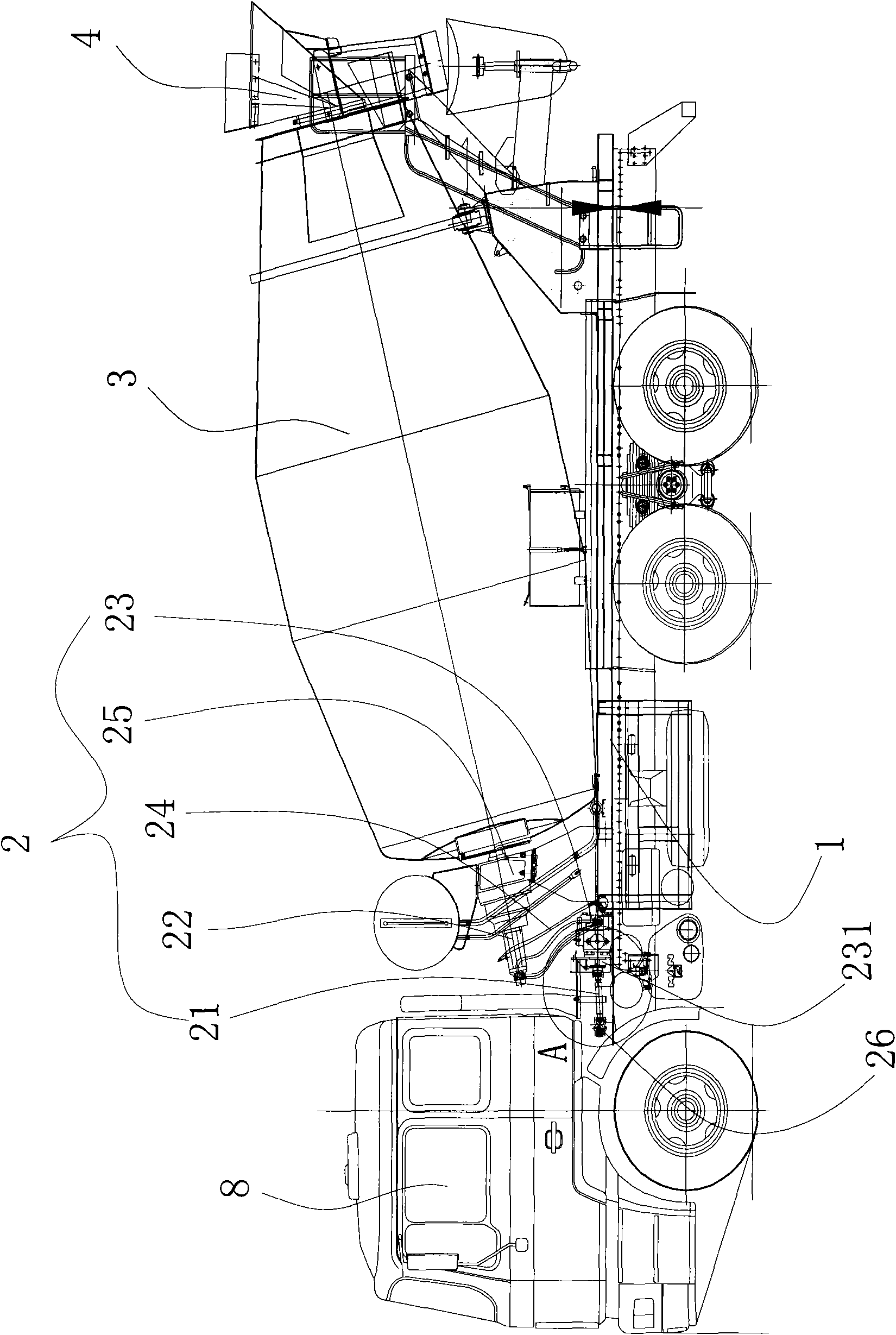

Safety device of transmission shaft of concrete mixer truck

A technology of a mixer truck and a safety device, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as fracture, concrete solidification, and easy damage to the drive shaft 21, and achieve the effect of preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

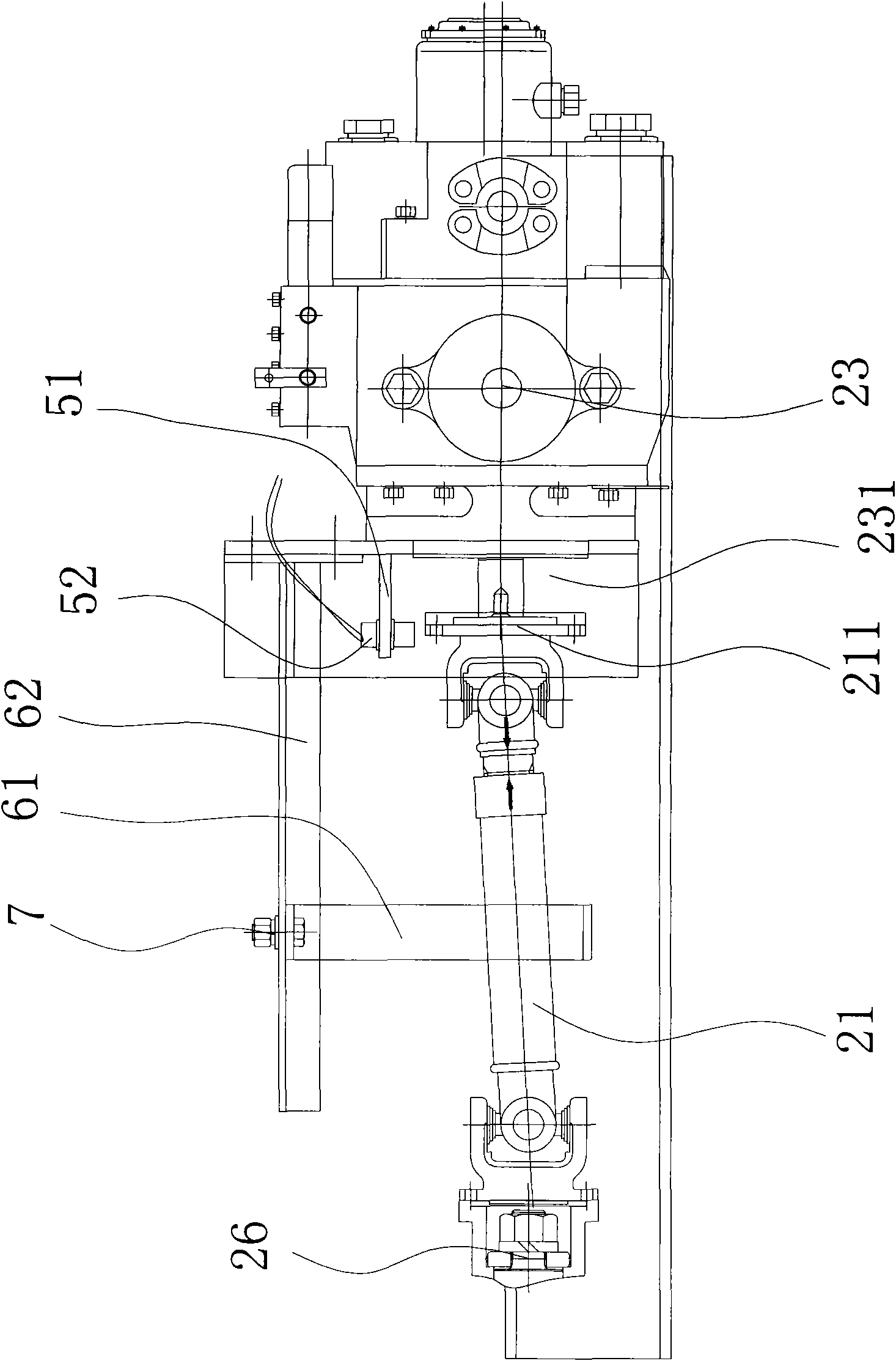

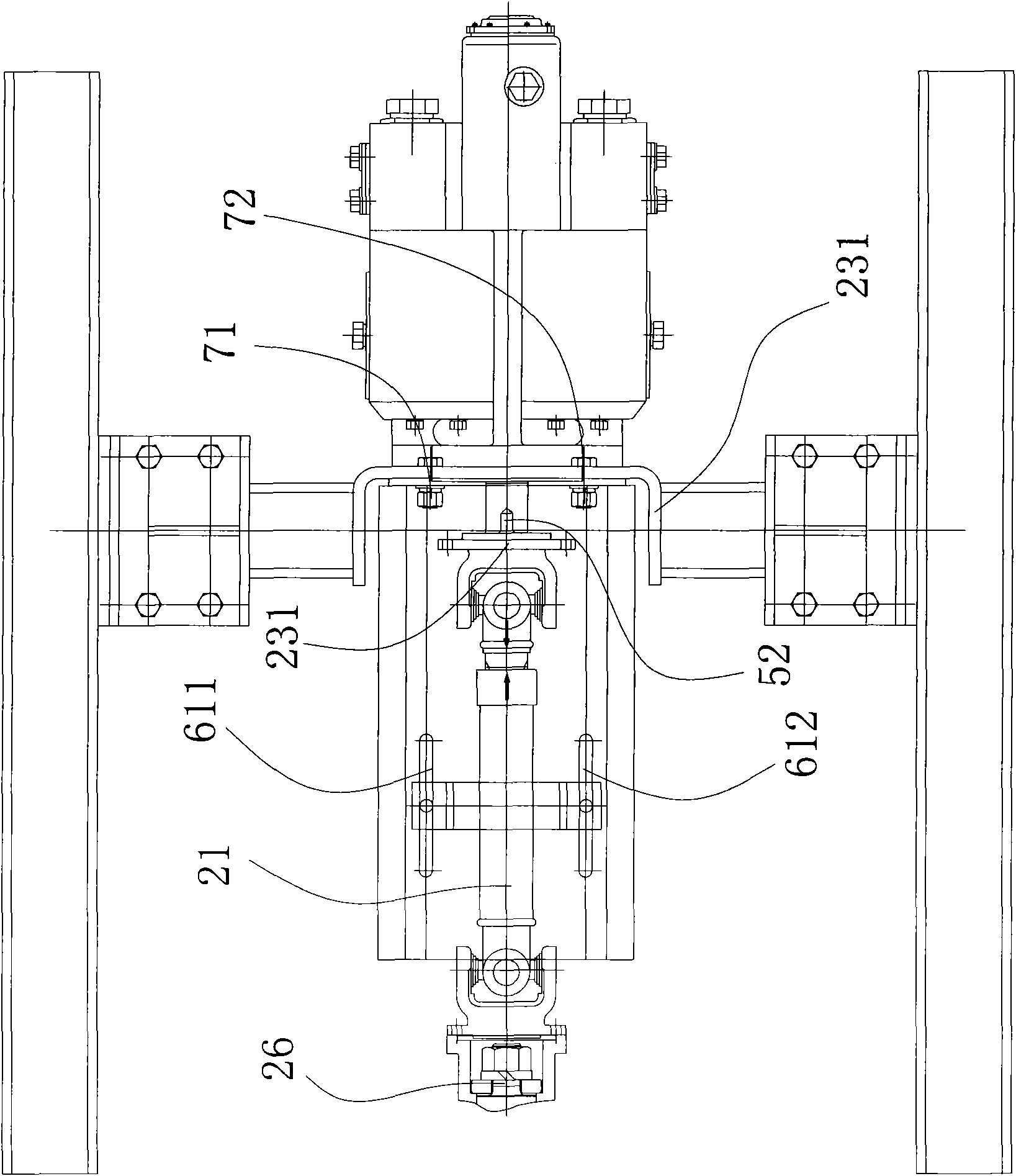

[0022] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings.

[0023] Such as figure 2 , 3 , 4, the safety device of the concrete mixer truck drive shaft of the present invention is a U-shaped piece 6 with an upward opening and a protective plate 62 for installing the U-shaped piece 61, two open ends 611 of the U-shaped piece 6, 612 are respectively connected with the bottom of the protective plate 62, usually by bolts 7. 26 in the figure is a power take-off, and its function and principle of action are the same as the concrete mixer truck of the prior art, so it will not be described in detail here.

[0024] The fixing of the protective plate 62 is carried out by using the pump bracket 231. The pump bracket 231 is used as the carrier of the hydraulic oil pump 23. The protective plate 62 can be fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com