Apparatus in a spinning room preparation, ginning or the like installation for detection of foreign matter in fibre material

A fiber material and spinning room technology, which is applied in the inspection of textile materials, analysis materials, measuring devices, etc., can solve the problems of high additional cost of equipment, occupying installation space, and insufficient detection, so as to save installation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

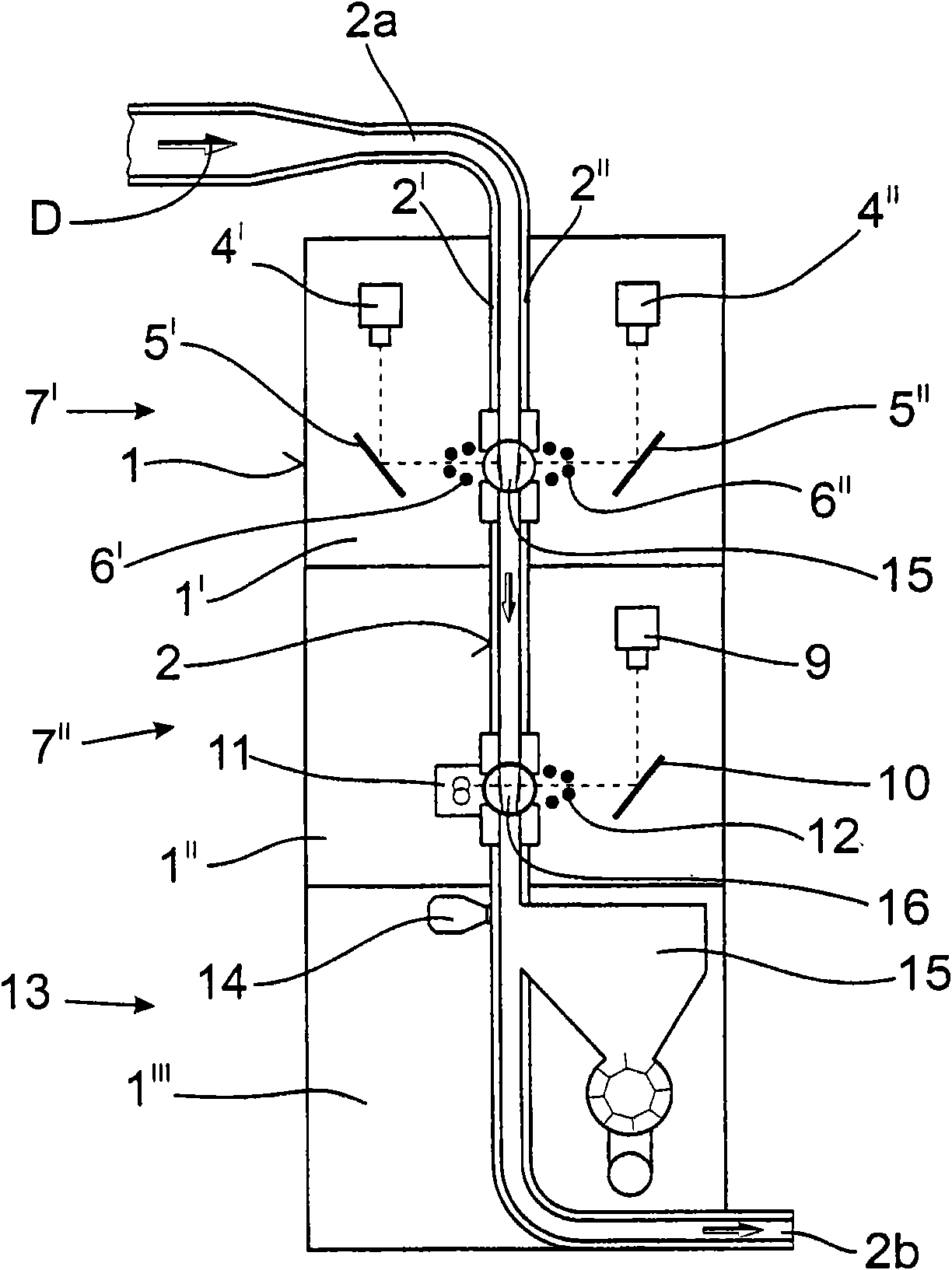

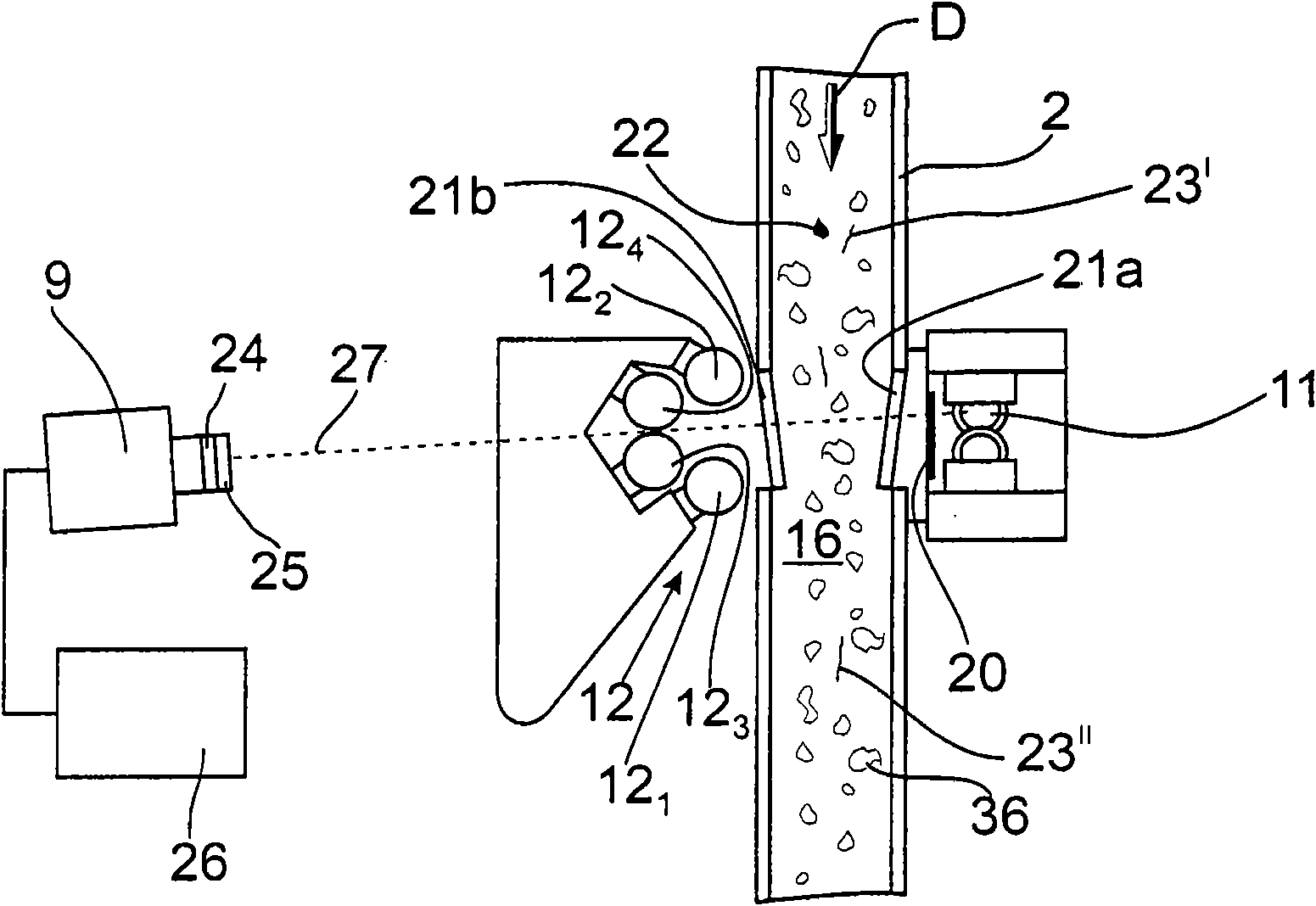

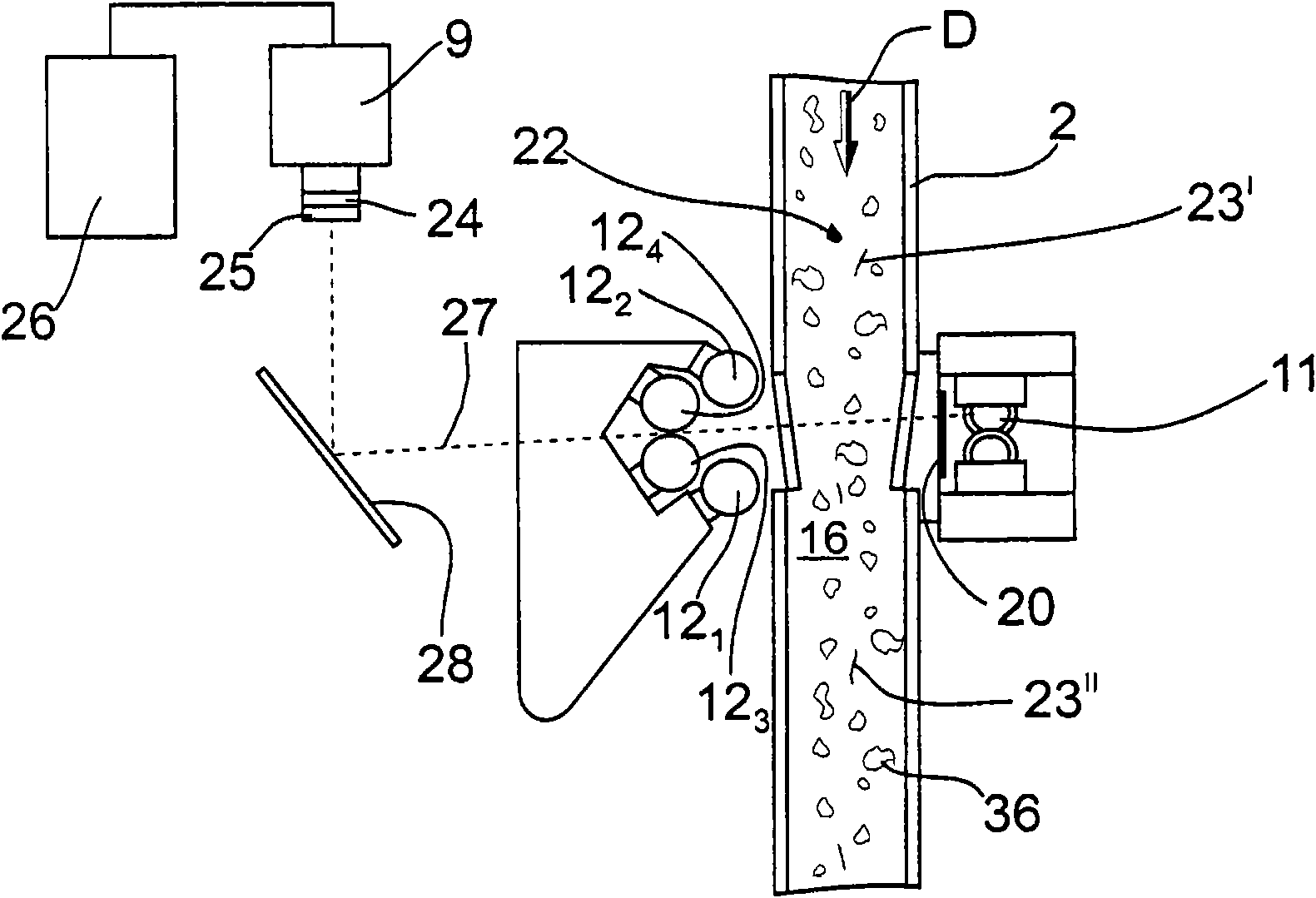

[0020] according to figure 1 , vertically arranged channels 2 are provided in the housing 1 . Parallel side walls 2 arranged opposite each other I ,2 II Constructed at least partially as transparent blocks (see figure 2 ). Irradiation unit with two side walls 2 I ,2 II connected outside.

[0021] The first detector device 3 comprises two CCD cameras 4 I 、4 II (line scan camera), the camera 4 I 、4 II through two inclined mirrors arranged at a certain angle 5 I and 5 II Applied indirectly to the glass channel 15. The optical planes are arranged slightly offset from one another. on channel 2 with camera 4 I A lighting system 6 is arranged on the opposite side I , and on channel 2 with camera 4 II A lighting system 6 is arranged on the opposite side II . In this way, the material in the glass channel 15 is detected by the two cameras 4 I 、4 II Check from both sides.

[0022] Enclosure 1 containing glass channel 15 I , camera 4 I and 4 II , tilting mirror 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com