Waterless closestool

A technology for waterless toilets and toilets, which can be applied to home appliances, applications, sanitary equipment, etc., can solve the problems of waste of water resources and ineffective water saving effects, and achieve the effects of saving water, reducing water costs, and avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

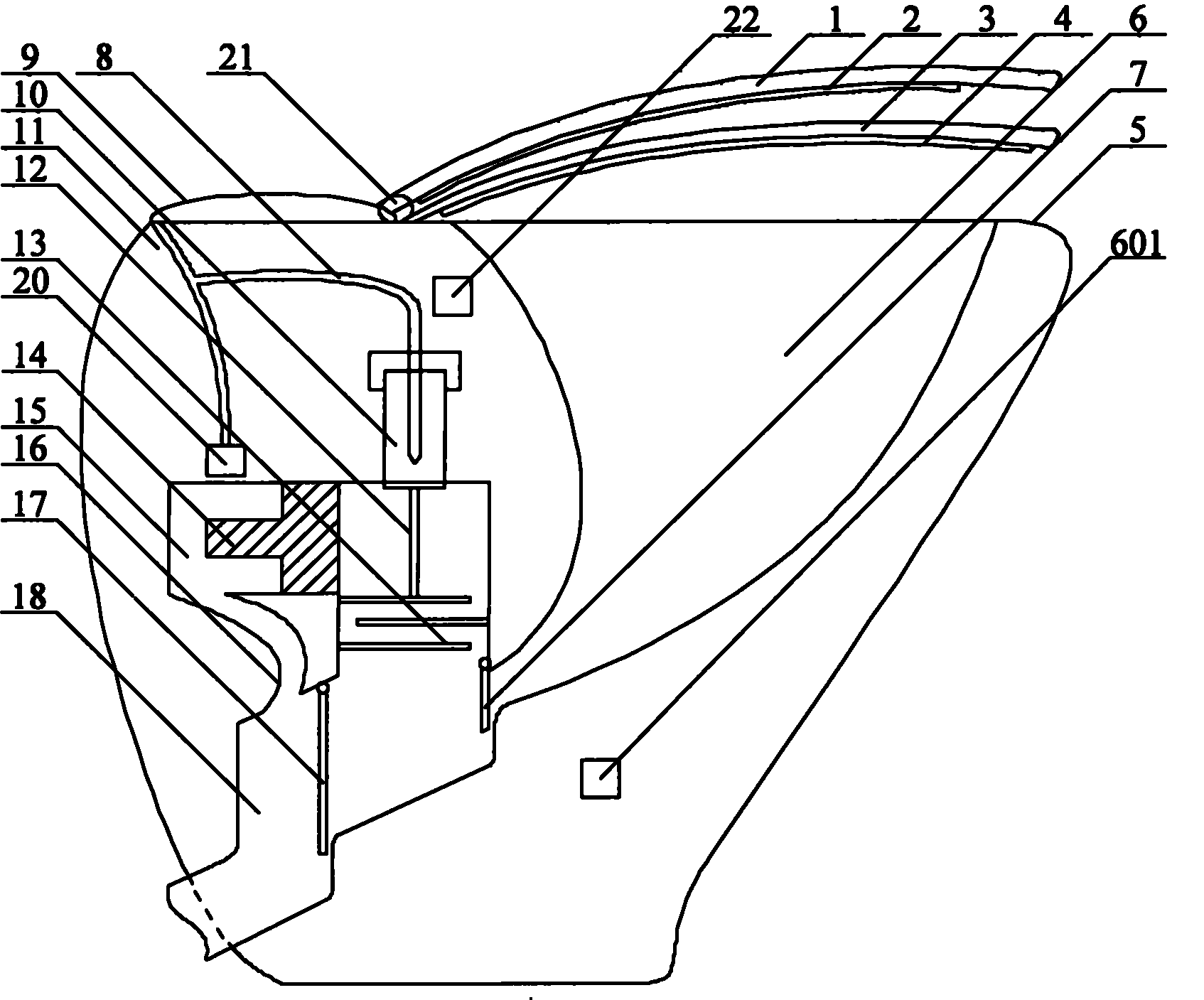

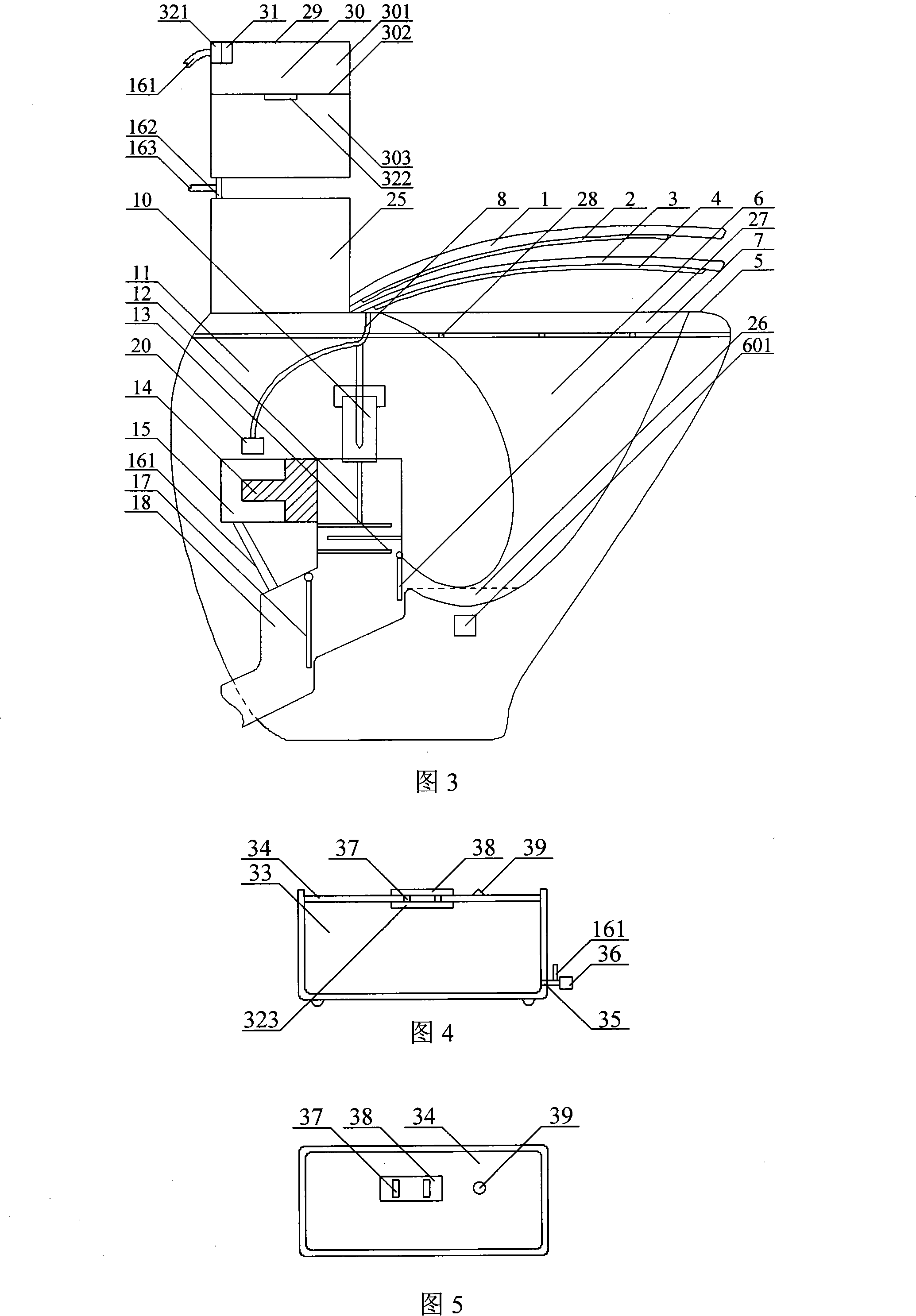

[0033] according to figure 1 As shown, a movable switch cover plate 1 and a seat plate 3 are fixed on the toilet body 5, wherein an upper sealing ring 2 made of silica gel is provided under the cover plate 1, and a lower sealing ring 4 is provided under the seat plate 3. After the cover plate 1 and the seat plate 3 are all closed, the urinal 6 of the toilet body is sealed; the bottom of the toilet body 5 is provided with a sewage pipe 18 for communicating with the outdoor sewage pipe, and the toilet body 5 is integrated with an installation. The warehouse 11 is provided with an upper cover 9, and the fixed pad in the installation warehouse 11 is provided with a suction and discharge device 15 of a sound-absorbing material. The suction and discharge device 15 includes an air pump 14, a suction and discharge pipe, an exhaust pipe, a filter screen 12 and a partition 13, etc.; The suction and discharge pipe has a first port connected to the suction port of the air pump, a second p...

Embodiment 2

[0037] The main difference between this example and the first example is that the cover plate 1 and the seat plate 3 do not need to add sealing rings, the urinal 6 is made of metal material, and a mechanical vibrating device 601 is set on the bottom of its inner wall, and the mechanical vibrating device adopts ultrasonic wave Vibrating head; after going to the toilet, when the flushing function is turned on, the ultrasonic vibrating head and the air pump 14 are activated at the same time, and the ultrasonic vibrating head vibrates at a high frequency millions of times per second, so that the excrement on the urinal 6 is separated from the inner wall of the urinal , and then inhale from the gap between the cover plate 1 and the seat plate 3 through a large amount of high-speed flowing gas, and clean the toilet after flushing the urinal.

Embodiment 3

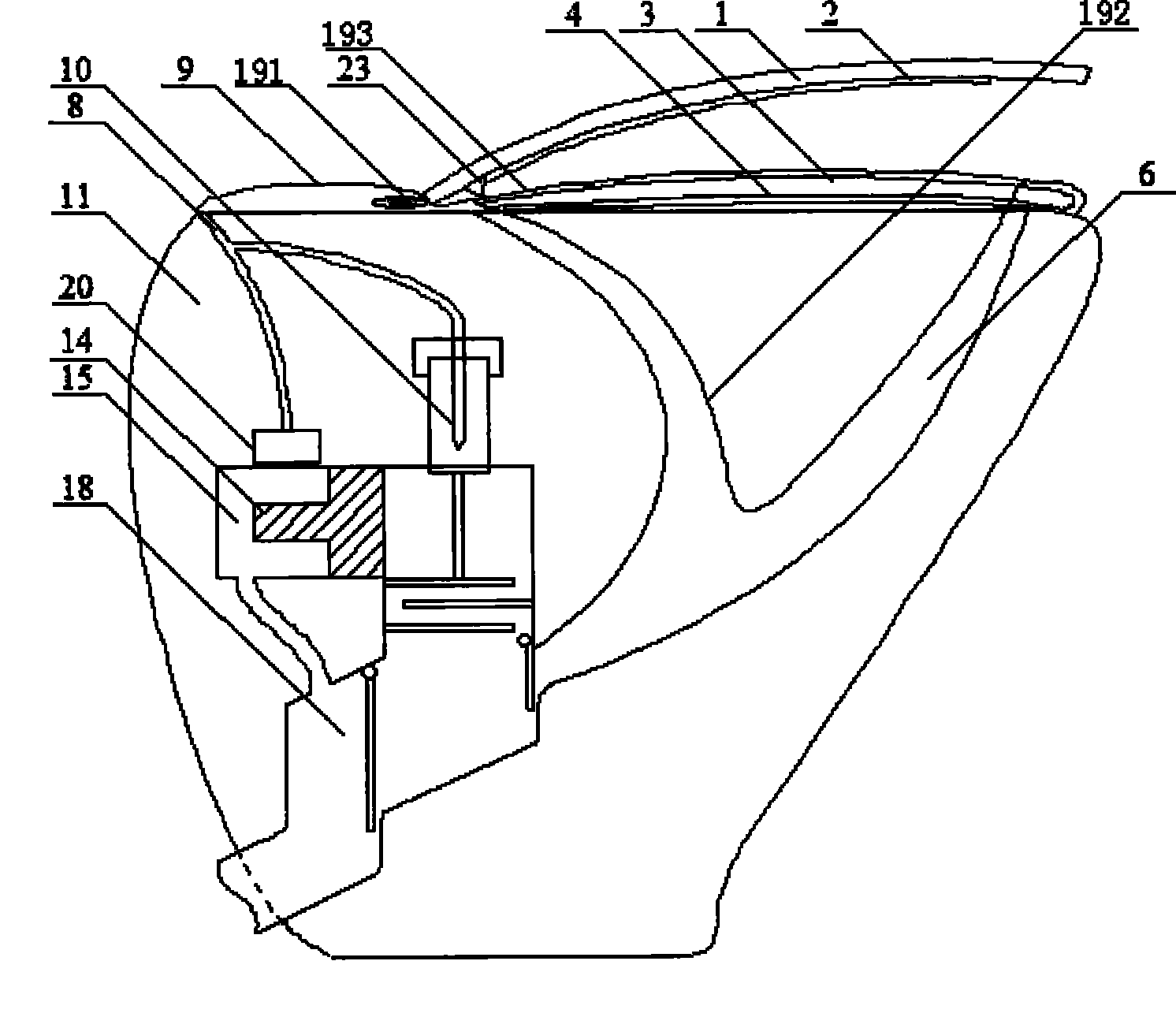

[0039] Such as figure 2 As shown, the main difference from Embodiment 1 is that in this example, a packaging bag roll seat is added in the upper cover 9 or the urinal wall to install the packaging bag roll 191. The material of the packaging bag can be environmentally friendly and decomposable plastics. Film and non-toxic and environmentally friendly synthetic materials or paper, the packaging bag is rolled into a round shape that can be used for 200 times, 100 times or 50 times, etc. There is a breaking line 193 between each package, and the cover plate 1 is hinged near A slightly protruding pressure line 23 is provided at the place. When the cover plate 1 is closed, the used packaging bag can be torn off by the break line 193 with a slight pressure. The packaging bag 192 has the shape of the urinal 6 under the use state, and can be put into the urinal 6. The mouth of the packaging bag can be placed on the seat plate 3. It is comfortable and hygienic to sit on the packaging b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com