Optimization method of hydrogenation reaction effluent air cooler system for preventing erosion of NH4HS

A technology for hydrogenation reaction and system optimization, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of many unplanned shutdown accidents and lack of correlation analysis in the REAC system, so as to reduce unplanned shutdown accidents and improve economic efficiency. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

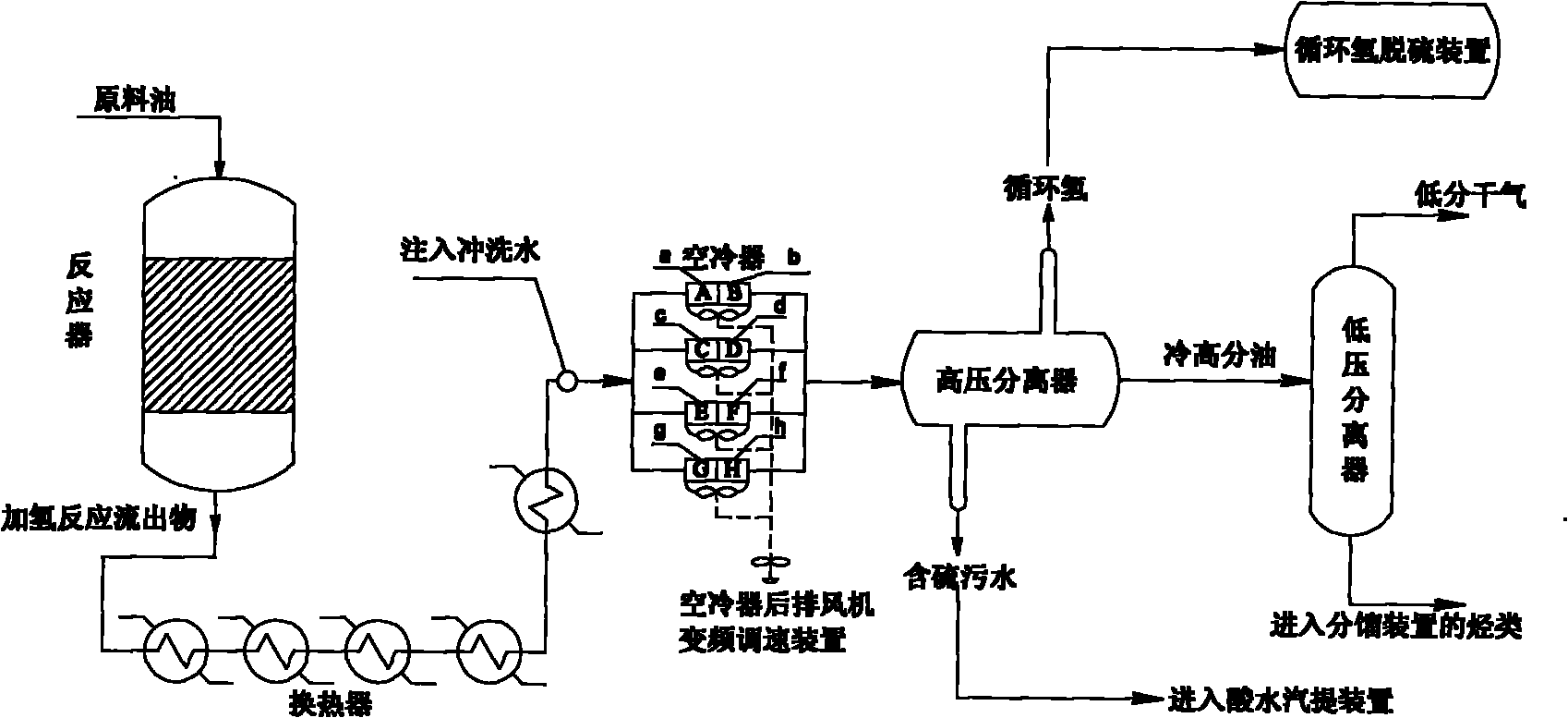

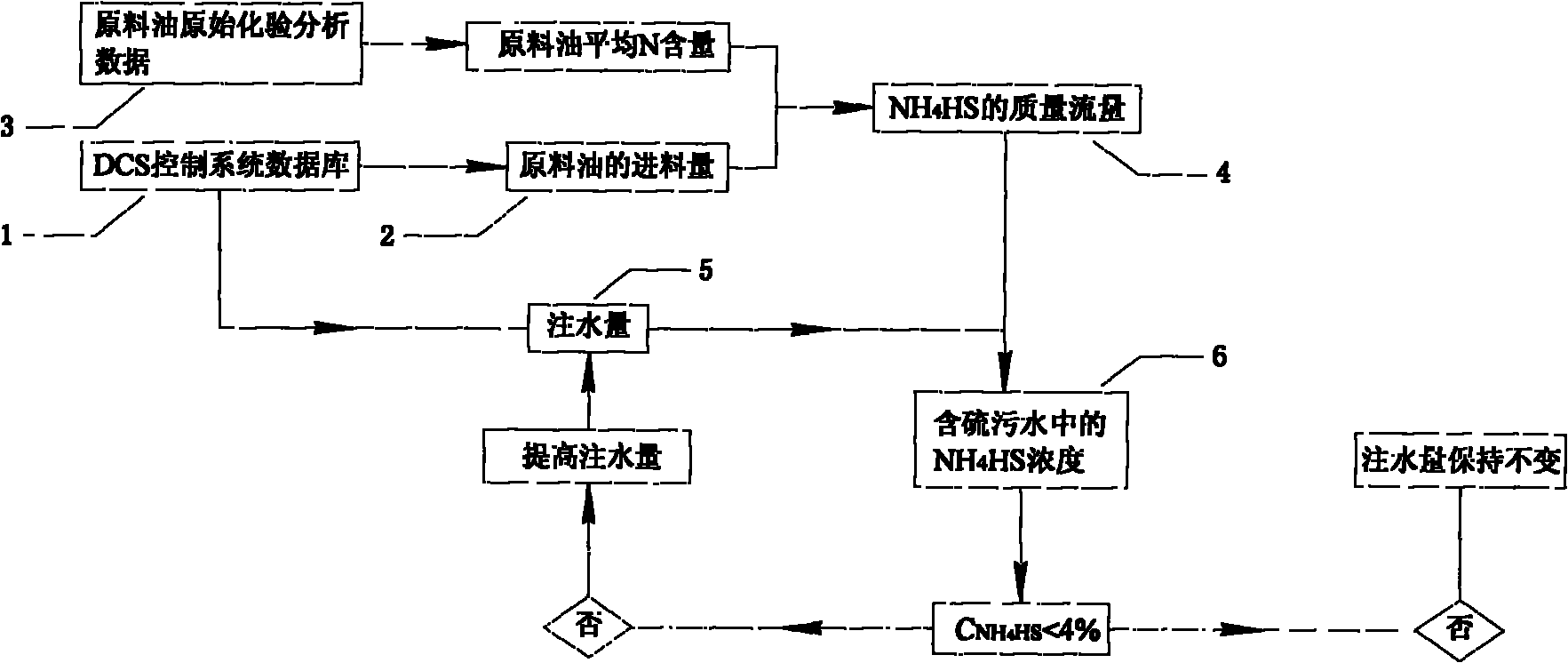

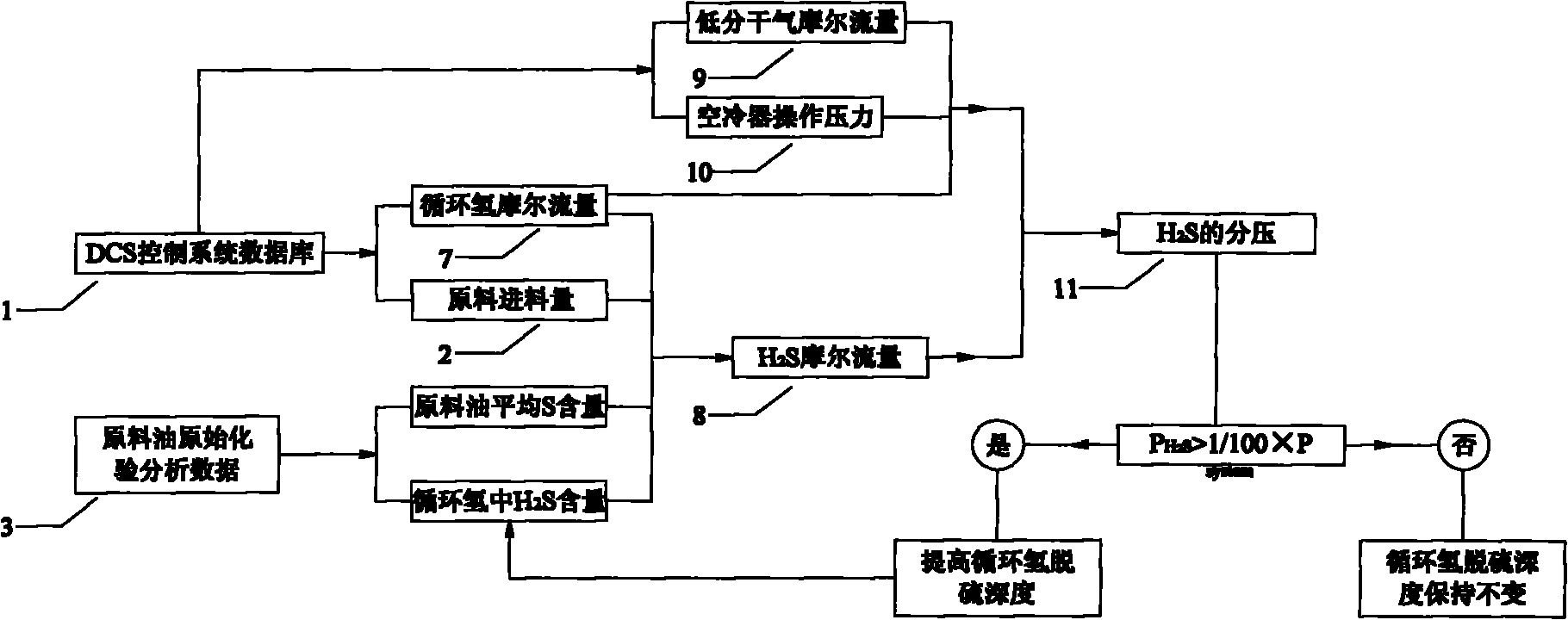

Method used

Image

Examples

specific Embodiment

[0050] It is known that the DCS control system database of a hydrocracking unit in a petrochemical enterprise includes: the raw material feed volume W of the hydrogenation reaction effluent system f 120t / h, water injection volume WW r 10t / h, the molar flow rate of circulating hydrogen mX 1 7151.4kmol / h, molar flow mX of low dry gas 2 66.96kmol / h, air cooler operating pressure P system 11.2Mpa, the outlet temperature of each air cooler (T i , i=1~8) T 1 38.02°C, T 2 34.37°C, T 3 39.92°C, T 4 36.54°C, T 5 35.44°C, T 6 35.52°C, T 7 41.51,T 8 43.13°C, the number of air coolers is i8;

[0051] Raw oil raw test analysis data include: average S content of raw oil F s 1.60%, the average N content of raw oil F n 800ppm, H in circulating hydrogen 2 S content F' s 3000ppm, the average molecular weight of circulating hydrogen mwX 1 5.54, the average molecular weight mwX of low dry gas 2 3.54, the density of the mixture at the inlet of the air cooler ρ58k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com