Hydrocracking reaction effluence system based on asymmetry analyse

A technology of hydrocracking and balance degree, which is applied in liquefaction, hydrocarbon oil cracking, refrigeration and liquefaction, etc. It can solve problems such as structural imbalance, corrosion failure of hydrocracking air cooler system, etc., so as to facilitate maintenance and replacement, reduce non-destructive Plan downtime accidents, make and install convenient and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

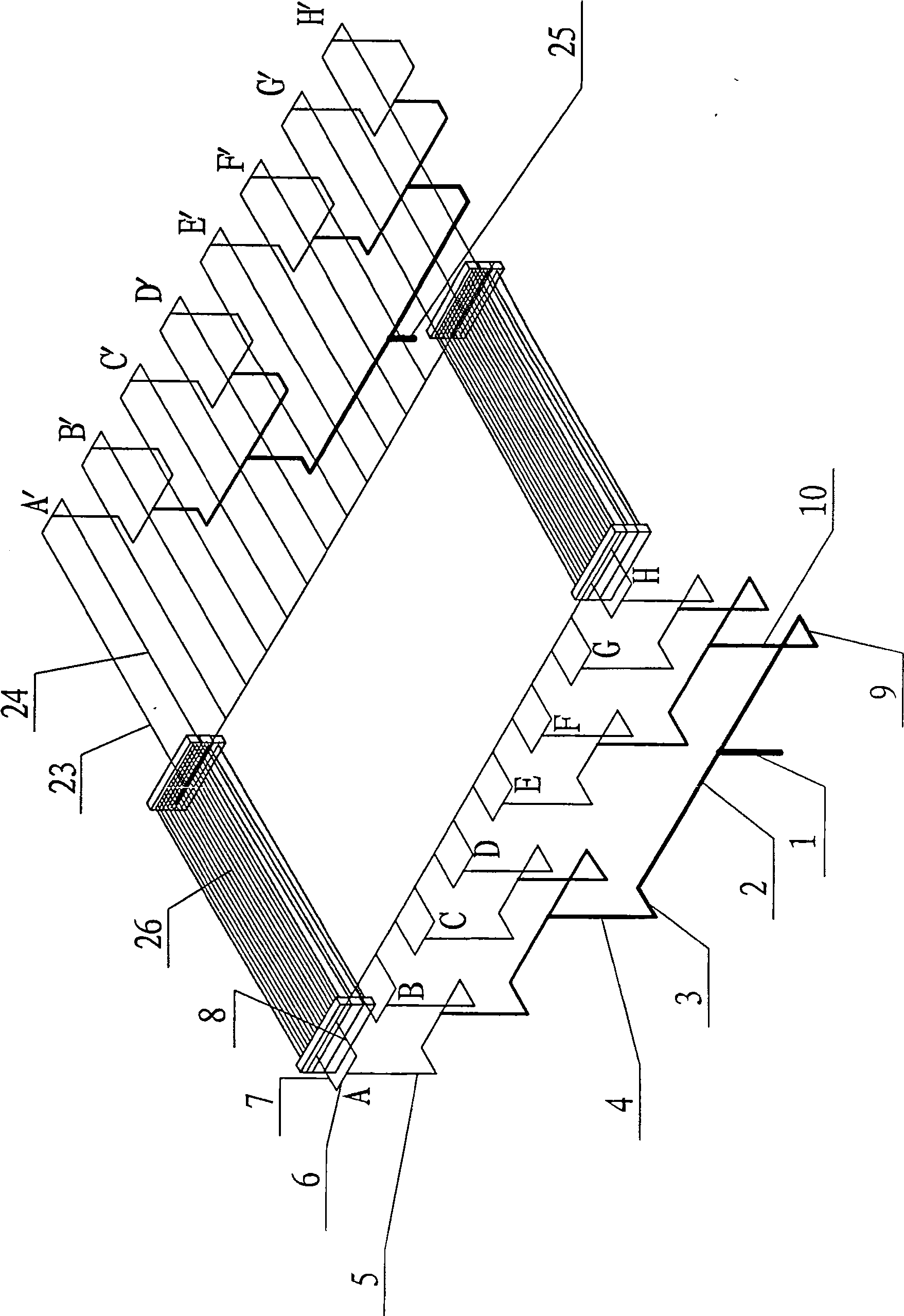

[0026] Such as figure 1 Shown is a structural schematic diagram of the present invention, including an inlet pipe part, an air cooler tube bundle part and an outlet pipe part;

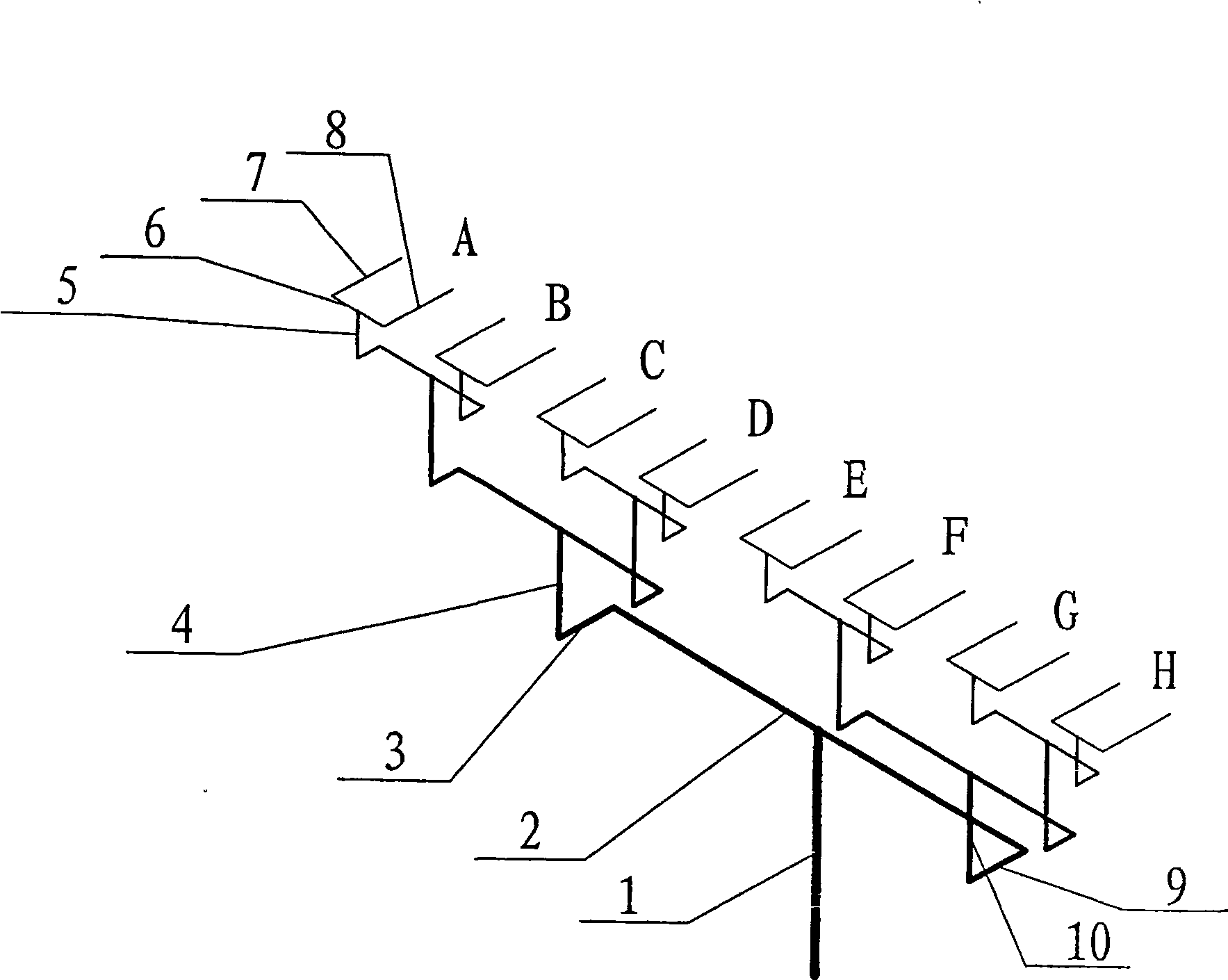

[0027] Such as figure 2As shown, the direction of the total inlet pipe 1 of the inlet pipeline part is vertically upward, and the end of the total inlet pipe 1 is connected vertically with the midpoint of the first pipeline 2 through the pipe fittings; , the third pipeline 9 is vertically communicated, and the second pipeline 3 and the third pipeline 9 are perpendicular to the plane formed by the total inlet pipe and the first pipeline 2; the fourth pipeline 4 is vertically communicated with the second pipeline 3 through pipe fittings, and The fourth pipeline 4 is perpendicular to the plane formed by the first pipeline 2 and the second pipeline 3; the fifth pipeline 10 and the third pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com