Pipeline configuration structure of triple-inlet air cooler system for hydrogenation reaction effluents

A technology of hydrogenation reaction and air cooler, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve problems such as ineffective effect, tube bundle leakage, high cost, etc., to avoid eddy current phenomenon, increase Uniformity, reducing the effect of multiphase flow erosion corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the drawings and embodiments.

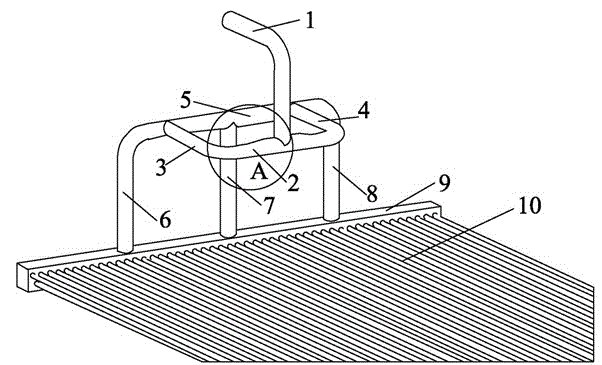

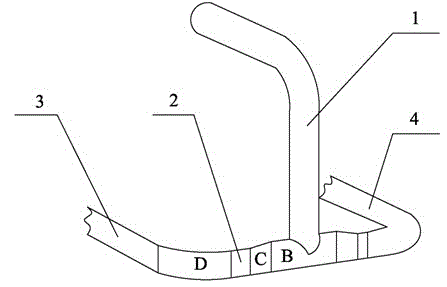

[0017] Such as figure 1 Shown is a schematic diagram of the structure of the present invention, including the inlet header 1, the first pipeline 2, the second pipeline 3, the third pipeline 4, the fourth pipeline 5, the fifth pipeline 6, the sixth pipeline 7, the seventh pipeline 8. Air cooler tube box 9, air cooler tube bundle 10. The inlet end of the main inlet pipe 1 is in the horizontal direction, and the outlet end is in the vertical downward direction. The horizontal section and the vertical section of the inlet main pipe 1 are connected by pipe fittings (90° elbow), and the vertical downward end of the inlet main pipe 1 passes through the tee first and then The reducing pipes at both ends are connected with the midpoint of the first pipe 2, and the two ends of the first pipe 2 are connected with the second pipe 3 and the third pipe 4 through pipe fittings (90° elb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com