A kind of method for smoke screen protection of boiler flue gas side

A boiler flue gas and smoke screen technology, applied in lighting and heating equipment, fluid heaters, etc., can solve the problem of easy corrosion and wear of the heating surface, so as to prolong the safe operation period, avoid erosion, wear and corrosion, and have a long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

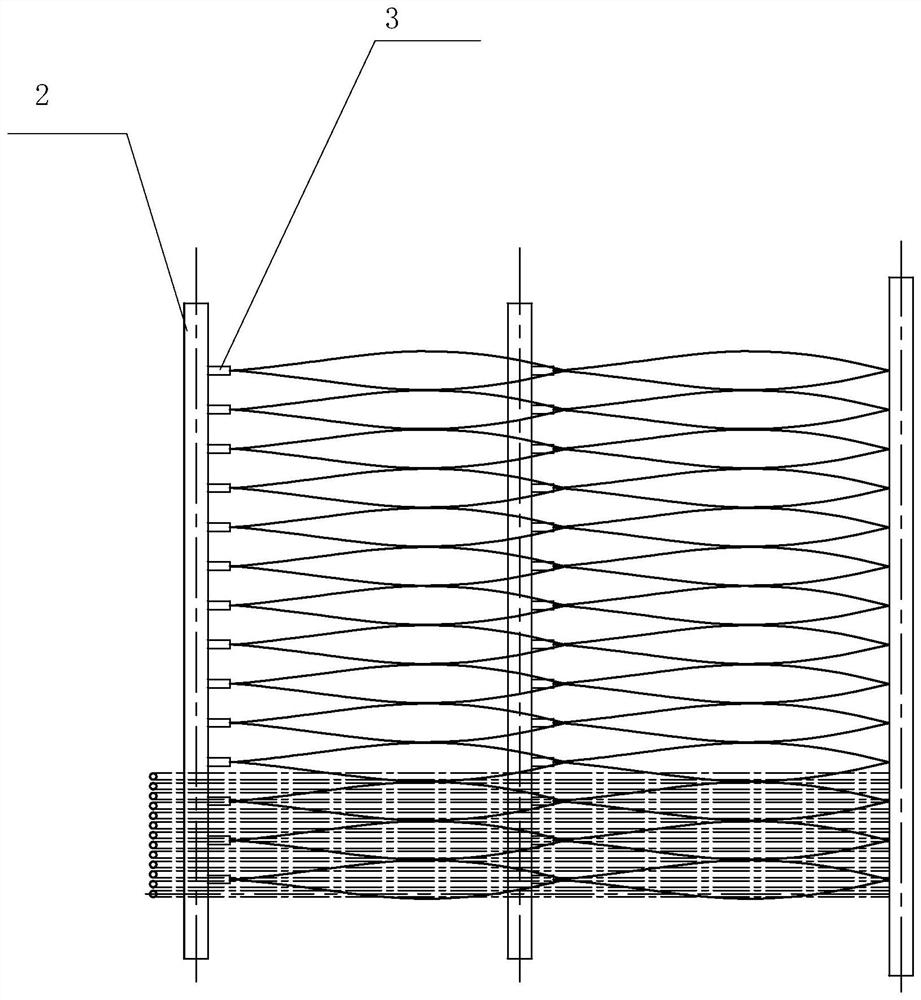

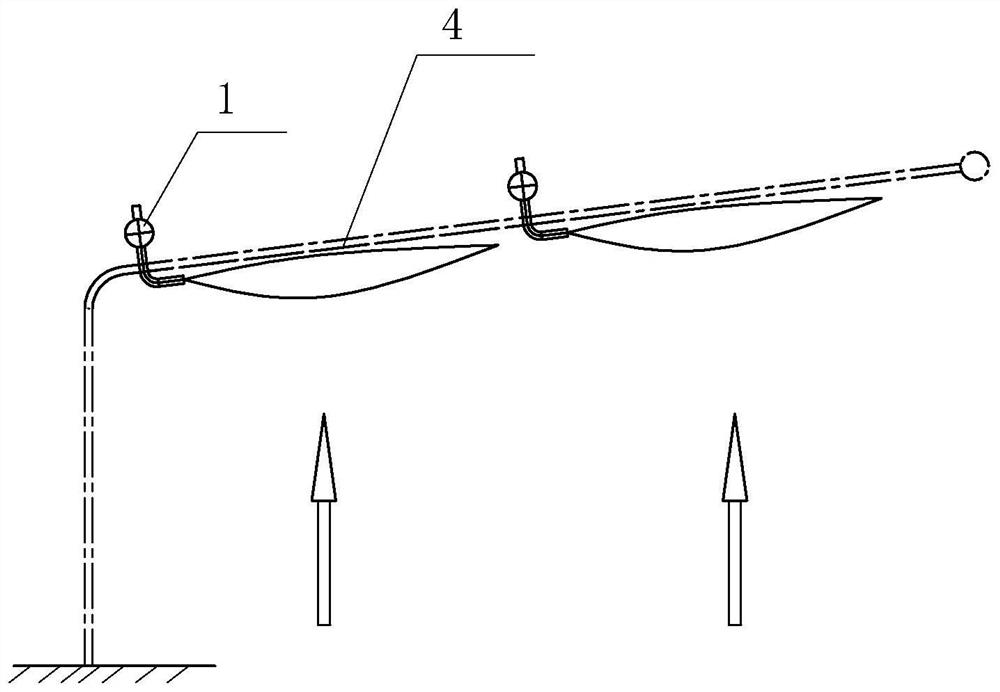

[0027] Depend on figure 1 combined with Figure 2-5 As shown, a method for protecting a smoke screen on the flue gas side of a boiler, the method comprises the following steps:

[0028] Step 1, clarify the target and determine the area 4 that needs to be protected in the boiler, so as to determine the area to be protected by the smoke screen s Y ;

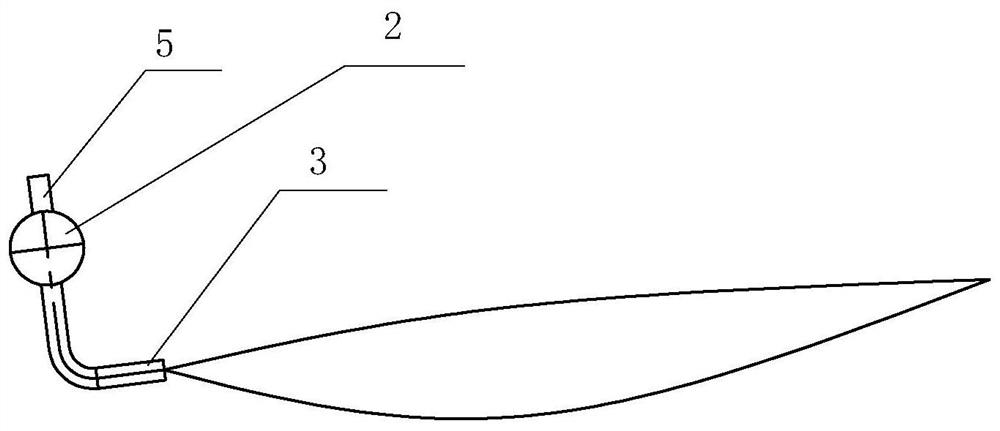

[0029] Step 2., setting an air curtain device, the air curtain device 1 includes a bellows 2 and a protection pipe 3, and the bellows is connected with a protective gas source; specifically, the bellows 2 is provided with a joint 5, so the The protective gas source described above is connected to the bellows through a joint. More specifically, the protective gas source can be air. The protective gas source can be a specific component gas, more specifically, the specific component gas is nitrogen.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com