Optimization method of water injection for hydrogenation reaction outflow air-cooler system

A technology of hydrogenation reaction and optimization method, applied in lighting and heating equipment, comprehensive factory control, flushing, etc., can solve the problems of corrosion leakage of REAC system, lack of clear research, lack of quantitative analysis of crystal deposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

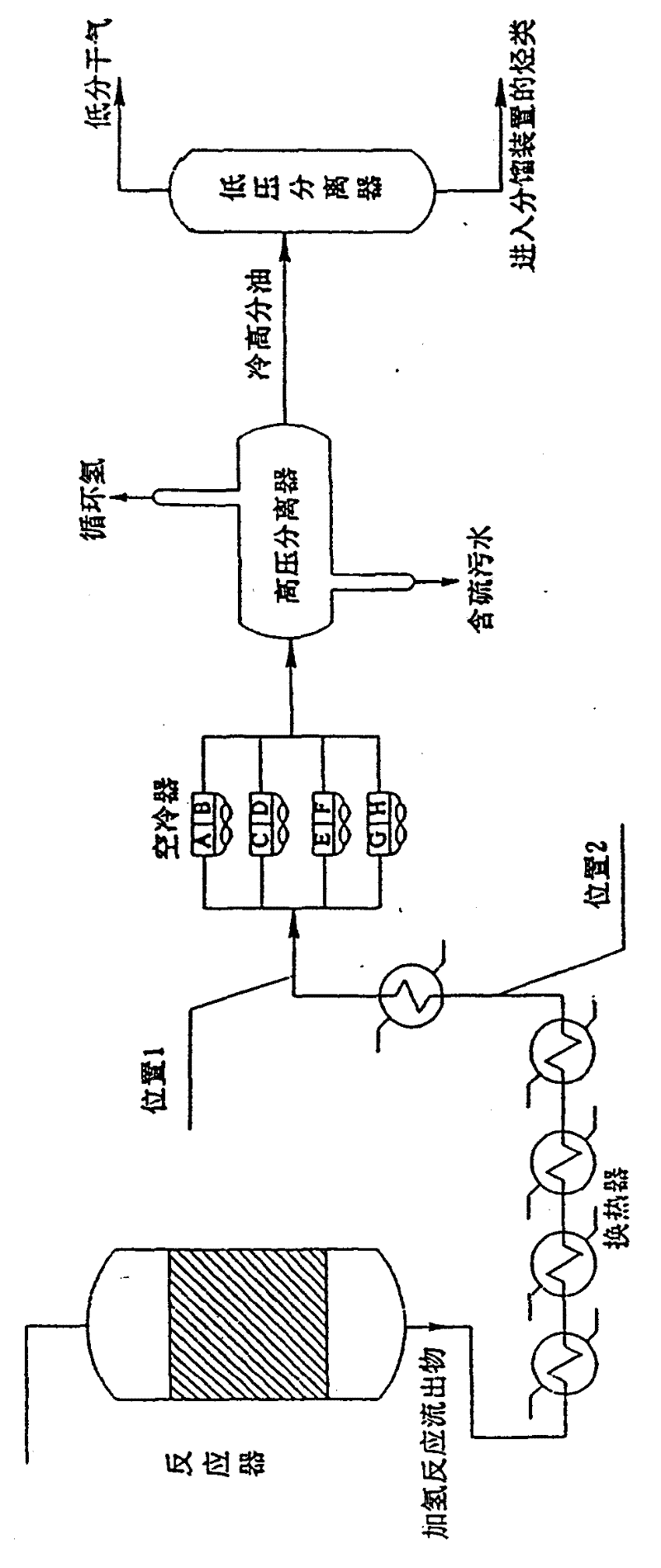

[0029] Such as figure 1 As shown, the hydrogenation reaction effluent flows out of the reactor, and after being cooled by 5 heat exchangers and 8 air coolers (codes A to H), three-phase separation is carried out in a high-pressure separator. Among them, the circulating hydrogen is separated from the top, the sulfur-containing sewage is discharged from the bottom, and the cold high-fraction oil directly enters the low-pressure separator, and the low-fraction dry gas and hydrocarbons entering the fractionation device are produced after secondary separation.

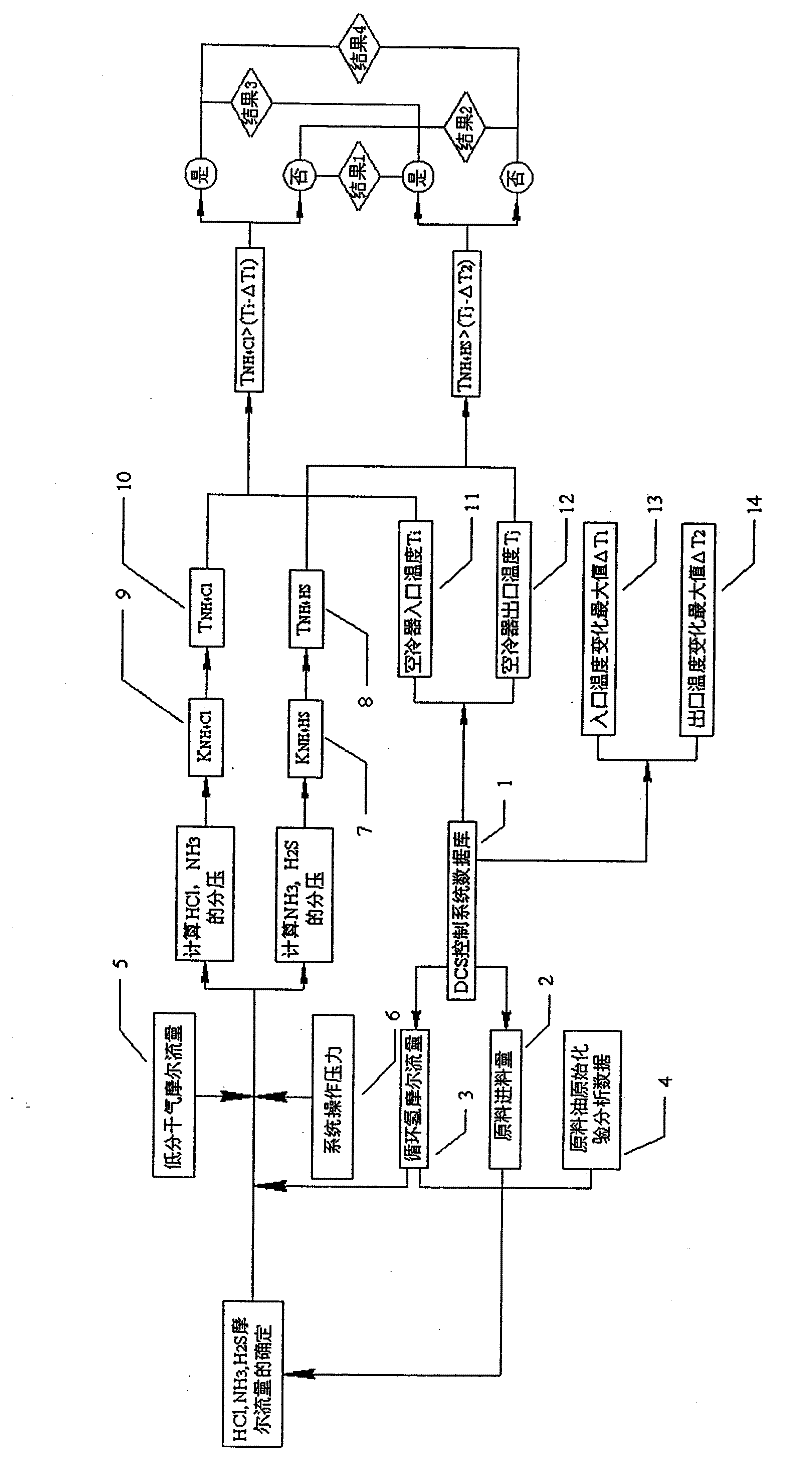

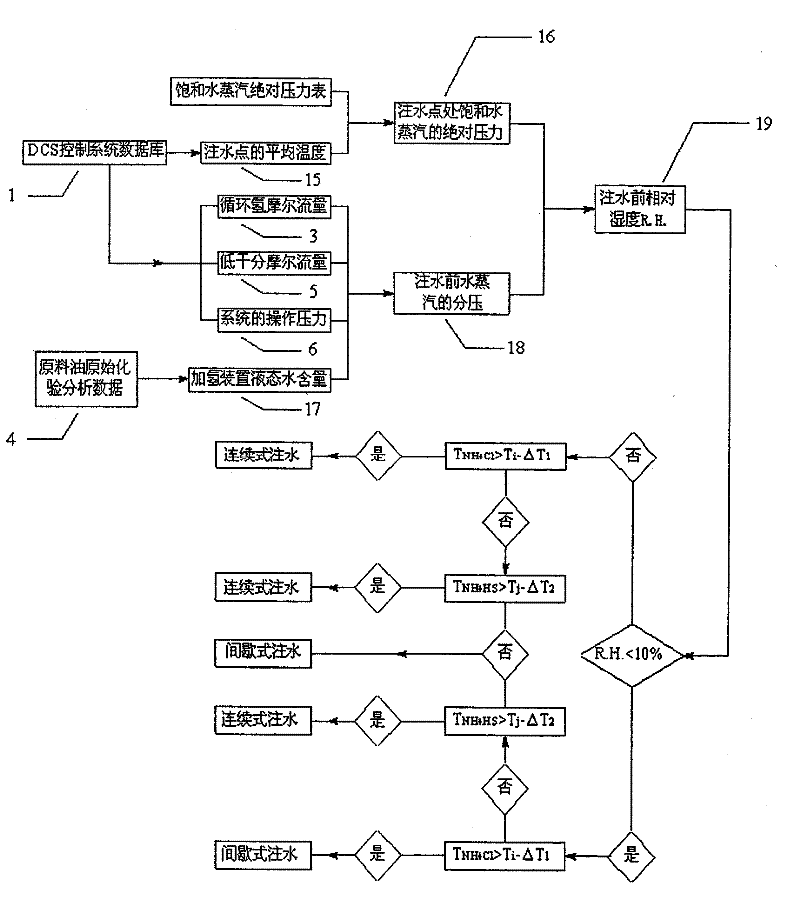

[0030] Since the hydrogenation reaction effluent contains HCl, NH 3 、H 2 Impurities such as S are easy to generate corrosive ammonium salts (NH 4 HS and NH 4Cl). The deposition of ammonium salts will not only block the tube bundles of heat exchangers and air coolers, but also cause serious under-deposit corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com