Touch screen and manufacturing method thereof

A manufacturing method and touch screen technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve problems such as cracking, broken screen, limited bending degree of glass, etc., and achieve good extrusion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

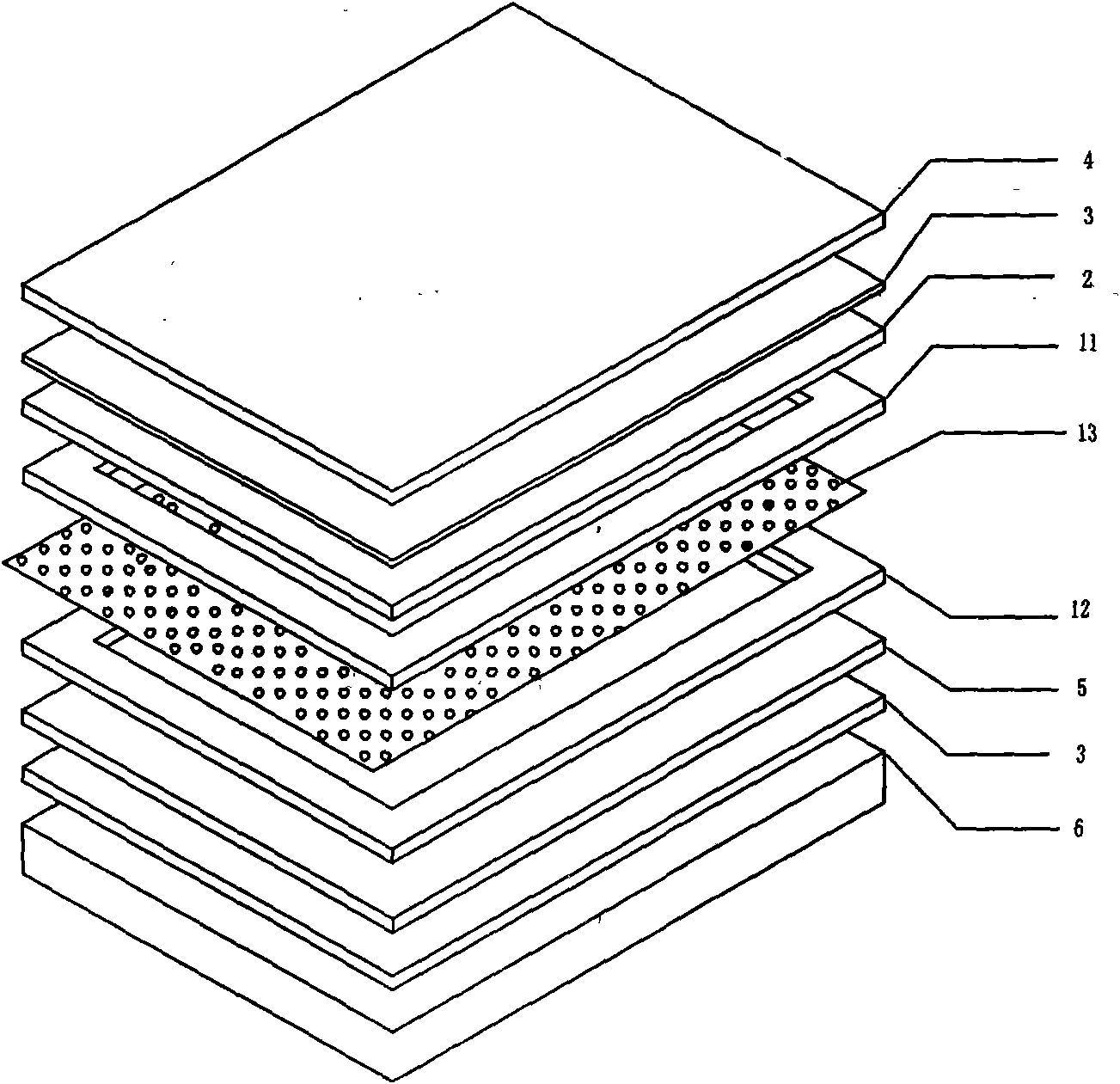

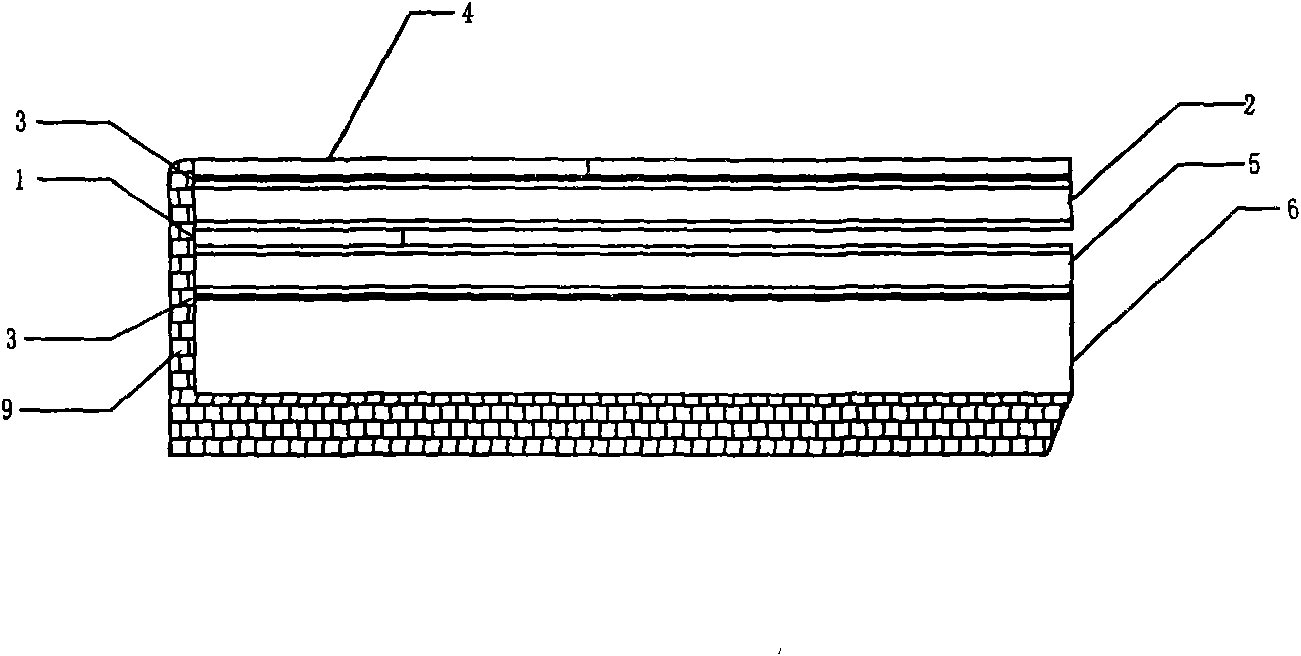

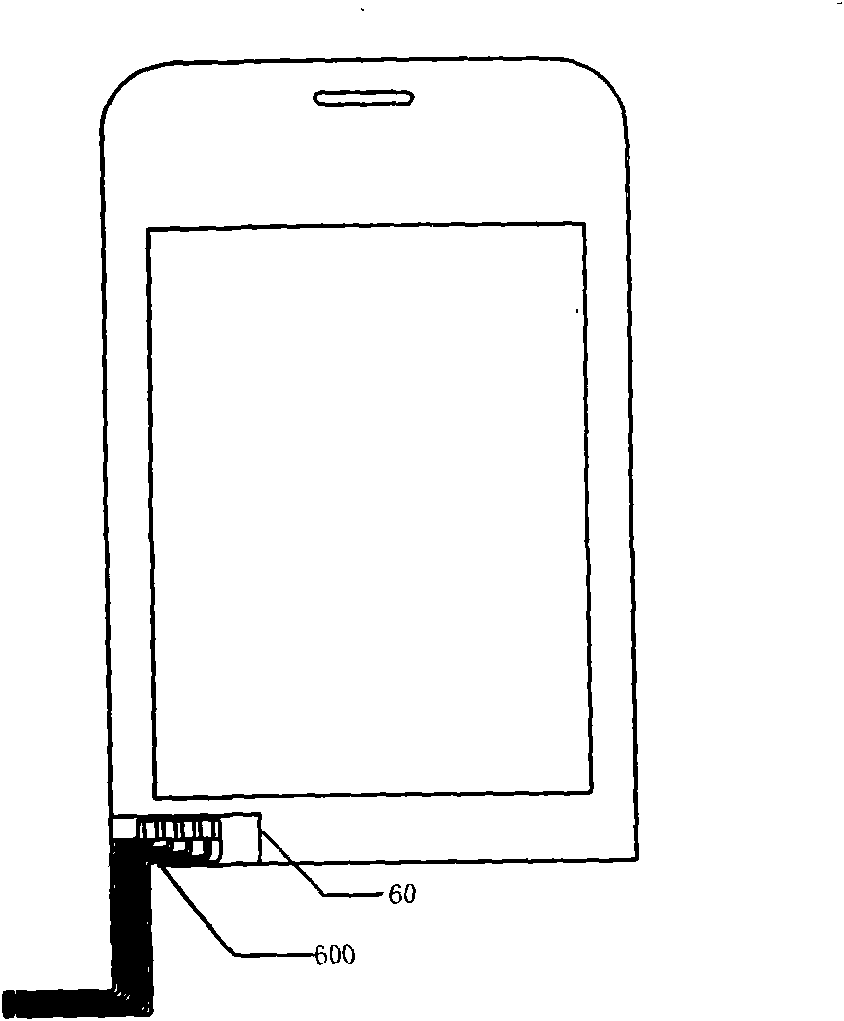

[0022] refer to Figure 1-3 , which are respectively the composition structure diagram of an embodiment of the touch screen provided by the present invention, the cross-sectional structure diagram after being installed in the casing 9, and the rear structure diagram; as shown in the figure, this embodiment mainly includes the following parts:

[0023] Circuit layer 1 and the leads 4 drawn from said circuit layer 1 (refer to image 3 );

[0024] The upper line ITO film 2 attached to the upper surface of the circuit layer 1;

[0025] Attach the mirror surface 4 on the upper surface (non-conductive surface) of the upper line ITO film 2 with a substrate-free optical adhesive tape 3;

[0026] The lower line ITO film 5 attached to the lower surface of the circuit layer 1;

[0027] The support plate 6 on the lower surface (non-conductive surface) of the lower ITO film 5 is pasted with the substrate-free optical adhesive tape 3 .

[0028] During specific implementation, the circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com