Generator system for wind power generation and variable speed control method

A generator and current controller technology, applied in wind power generation, control generators, control systems, etc., can solve problems such as torque ripple, motor heating, large harmonic current, etc., to simplify parallel combination, reduce losses, eliminate The effect of the third frequency pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

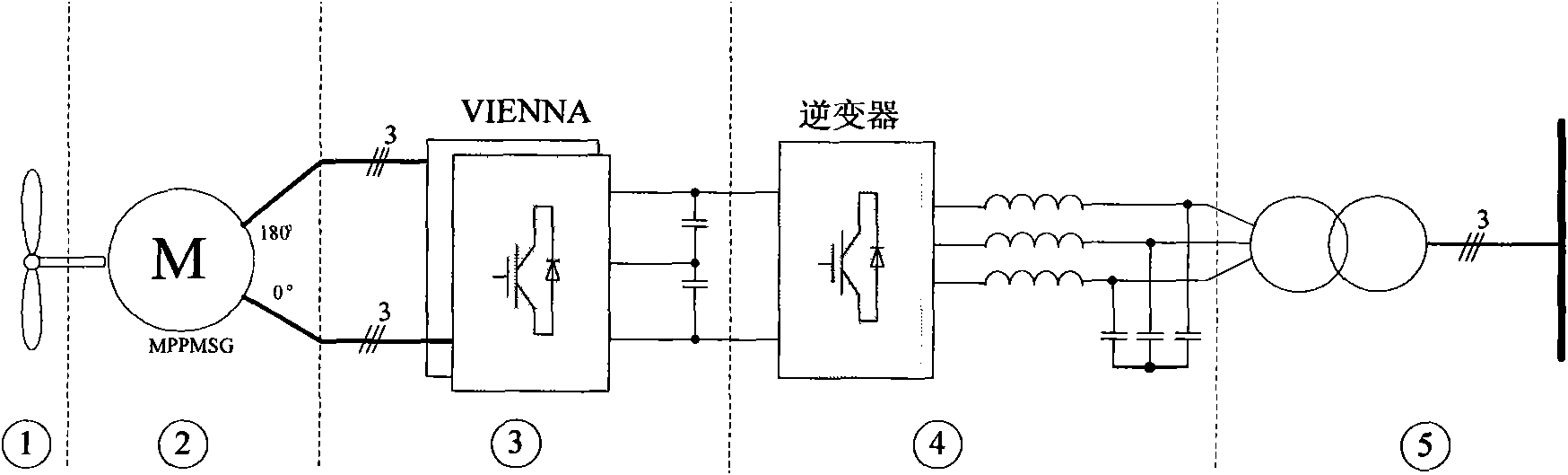

[0034] generator system

[0035] figure 1 The overall structure of a generator system for wind power generation is given, which is composed of five main parts, including a permanent magnet synchronous generator ②, the power input of the permanent magnet synchronous generator is connected to the fan ①, and realizes the transformation of mechanical energy into electrical energy. The electric energy output is connected to a Vienna rectifier device ③ to realize the conversion from mechanical energy to electric energy. The Vienna rectifier device realizes the AC-DC conversion of electric energy, and at the same time realizes the variable speed operation control of the fan, and its output is connected to a grid-connected inverter ④; The grid-connected inverter ④ feeds power to the grid through a step-up transformer ⑤ to realize DC-AC conversion of power while main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com