Single-board or single-column back flush purifying device

A purification device and backwashing technology, applied in chemical instruments and methods, fixed filter element filters, filtration and separation, etc., can solve problems such as inability to ensure purification effect, inability to continuously filter and purify, affecting product production efficiency, etc. The effect of material exhaust, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

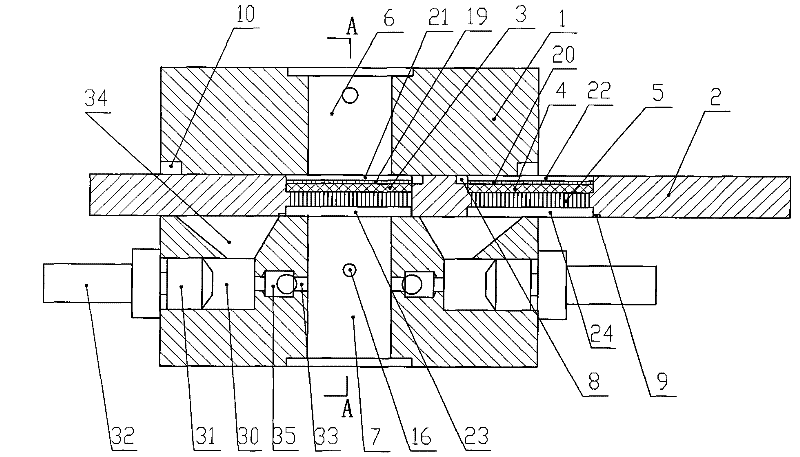

[0035] Embodiment one: if figure 1 and Figure 4 As shown, the single-plate or single-column backwash purification device of the present invention includes a body 1, a cuboid-shaped through hole is horizontally provided in the body 1, and a feed channel 6 and an outlet channel 6 communicated with the cuboid-shaped through-hole are longitudinally provided. Feed channel 7, the cuboid through hole is provided with a reciprocating plate 2 that is slidably connected to it, and the reciprocating plate 2 is provided with a sinking tank 21 and a sinking tank that can be connected to the feeding channel 6 on the side adjacent to the feeding channel 6 22. The centers of the sinkers 21 and 22 are located on the centerlines of the feed channel 6 and the discharge channel 7, and the adjacent nearest distance between the sinker 21 and the sinker 22 is half the width or diameter of the sinker 21 and 22 Correspondingly, the size of sinker 21 and sinker 22 is equivalent to the cross-sectional...

Embodiment 2

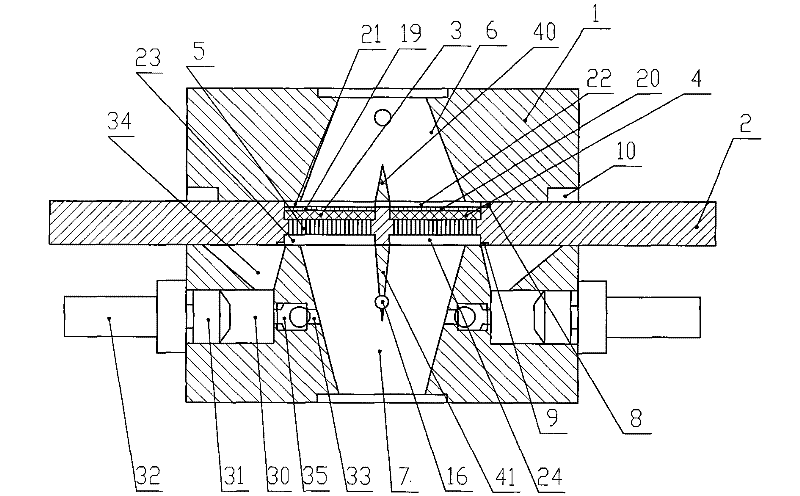

[0037] Embodiment two: if figure 2 As shown, the difference from Embodiment 1 is that: first, a split rib 40 and a splitter rib 40 that separates the feed channel 6 and the discharge channel 7 into two parts are longitudinally provided in the feed channel 6 and the discharge channel 7 respectively. The ribs 41, the two parts of the feed channel 6 and the two parts of the discharge channel 7 are connected through the filter screen 3 and the filter screen 4 respectively, so that the effective filter area is increased and the working efficiency is increased. Second, the size parameters of the sinking tank 21 and the sinking tank 22 and the feed channel 6 and the discharge channel 7 are not limited.

Embodiment 3

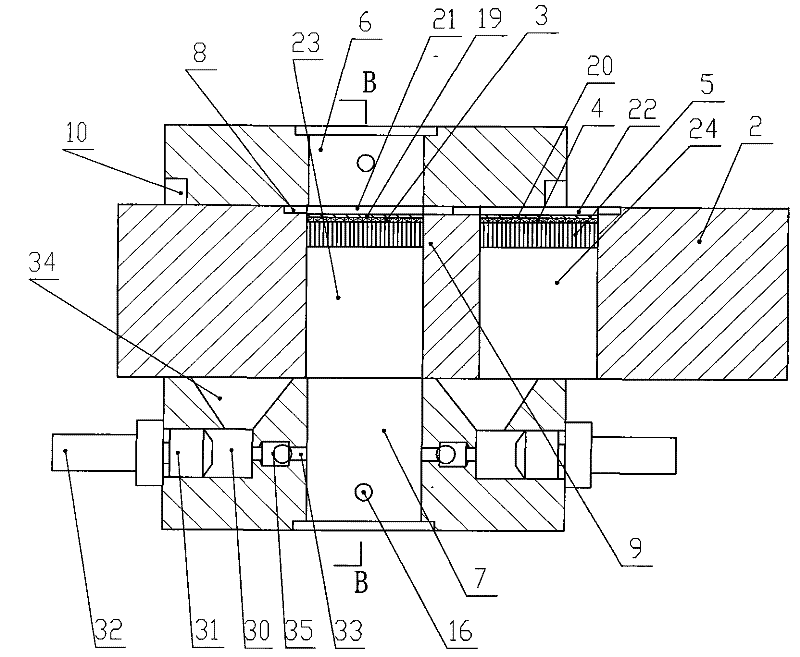

[0038] Embodiment three: as image 3 and Figure 5 As shown, the difference from Embodiment 1 is that the shape of the through hole arranged laterally on the main body 1 is cylindrical, and the reciprocating column 2 is provided in the through hole to slide and fit with it, and the sinking grooves 21 and 22 on the reciprocating column 2 It is a semi-cylindrical ring, the axial direction of the filter hole 5 points to the center of the same cross-section, and the grooves 23 and 24 are arranged longitudinally inward and communicate with the filter hole 5 . Of course, if Figure 6 As shown, the structure of the sinkers 21, 22 can also be in the shape of a inferior arc cylinder, and the filter screens 3, 4 are rectangular or circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com