Direct water-supply type heat storage activation method and direct water-supply type heat storage activation furnace

An activation method and activation furnace technology, applied in the field of direct water-feeding heat storage activation furnace, can solve the problems of increased production equipment cost, increased activated carbon production cost, air pollution, etc., and achieve simple and convenient transformation, reduced production cost, and capital investment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

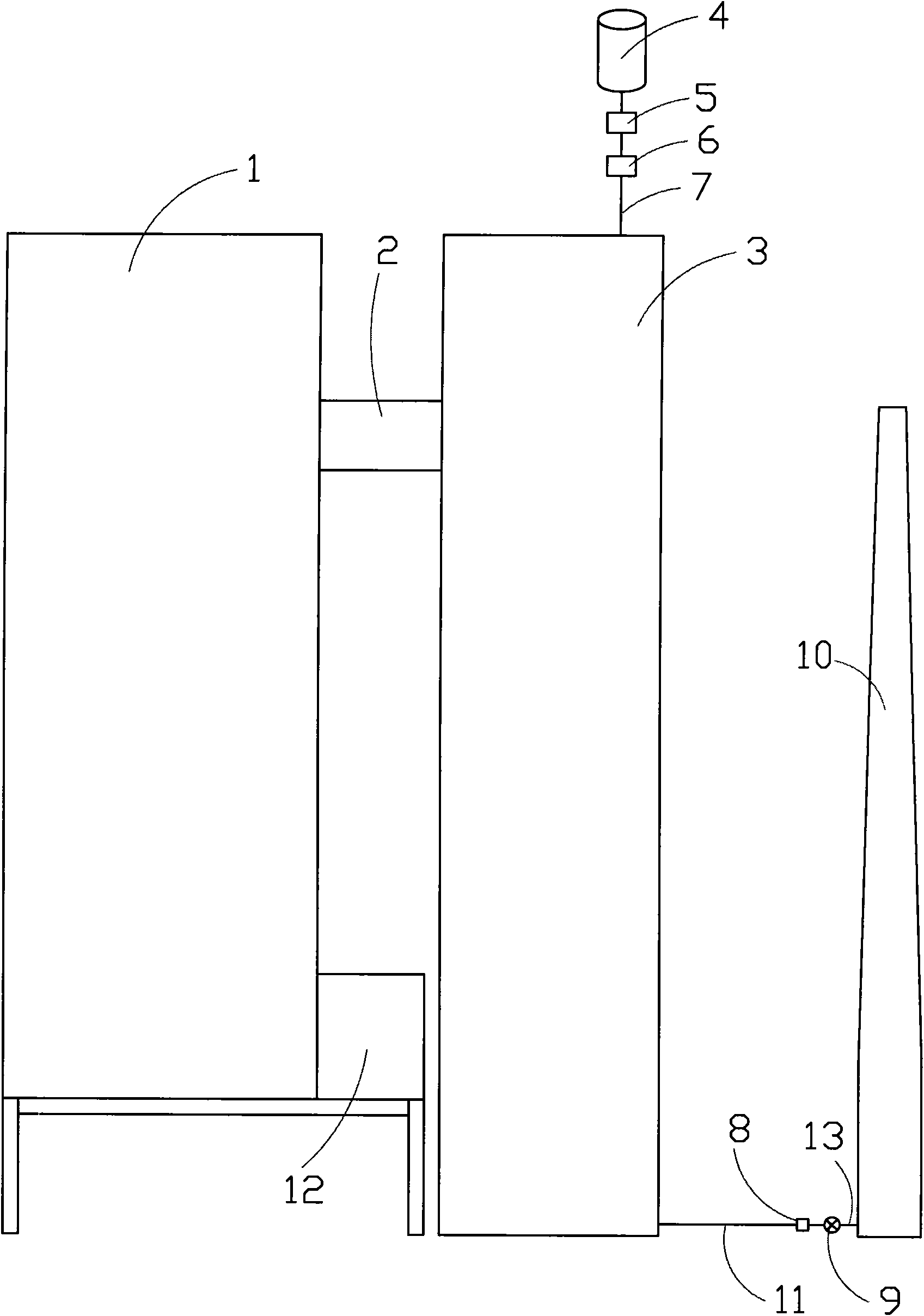

[0014] The direct water-feeding heat storage activation method involved in the present invention is to directly inject water into the regenerator 3 of the activation furnace, and additionally increase the energy compensation for the water-filled regenerator 3, through energy compensation to make up for the energy after water injection. The drop of the temperature at the top of the regenerator 3 ensures the working temperature of the activation zone in the main body 1 of the activation furnace.

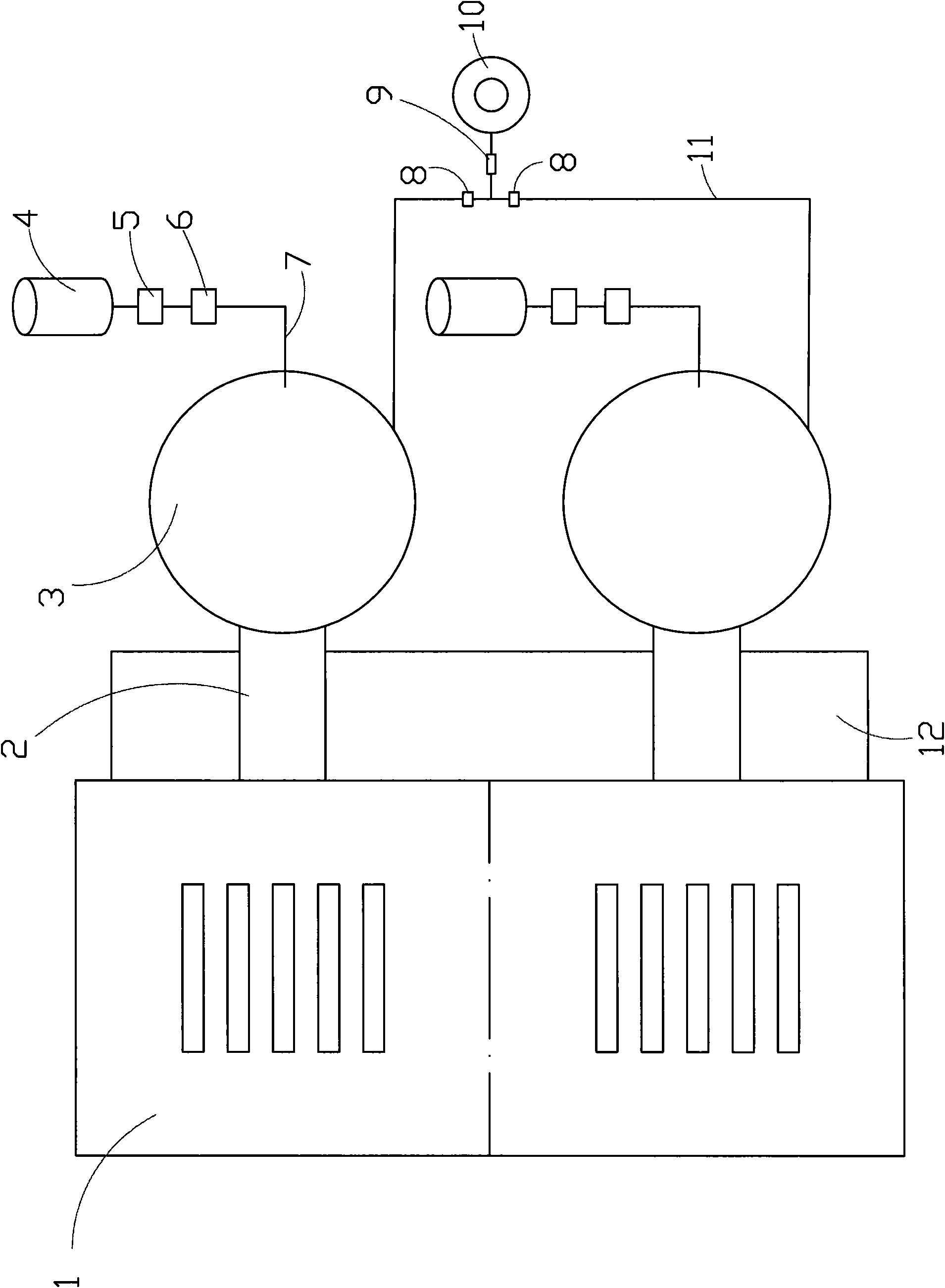

[0015] As shown in the figure, the direct water-feeding heat storage activation furnace involved in the present invention includes two activation furnace main bodies 1, a combustion chamber 12, two heat storage chambers 3, two upper connecting flues 2 and a flue exhaust duct 10, The combustion chamber 12 is arranged inside the main body 1 of the two upper activating furnaces, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com