Steering test bench of electrical-closed tracked vehicle transmission device

A transmission and steering test technology, which is used in vehicle testing, machine gear/transmission testing, measuring devices, etc., can solve the problem of large power loss of the test bench, the inability to complete the steering test of the crawler vehicle transmission, and the inability of the power of the loading device to directly For problems such as the use of the driving device, to achieve the effect of saving experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

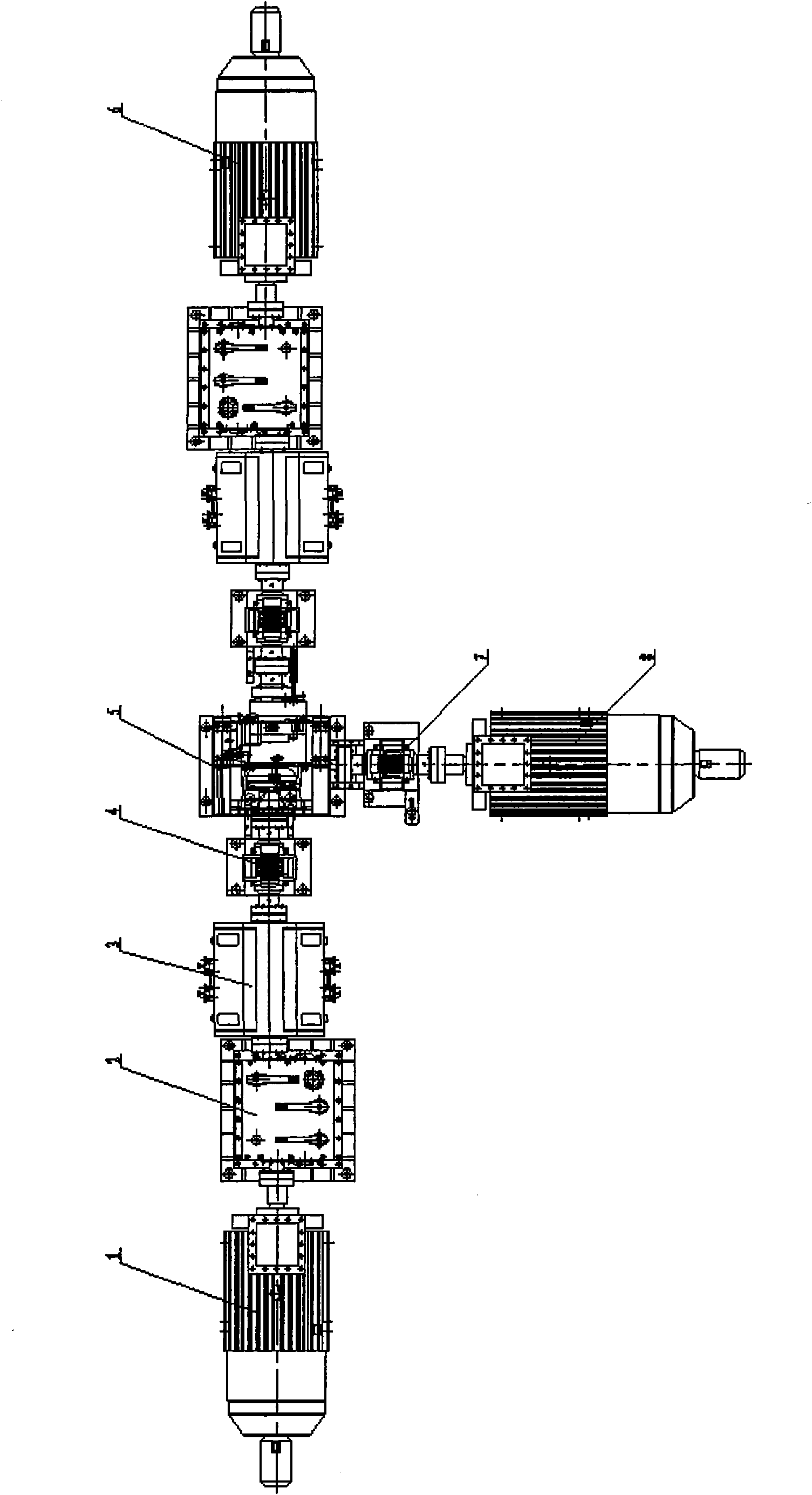

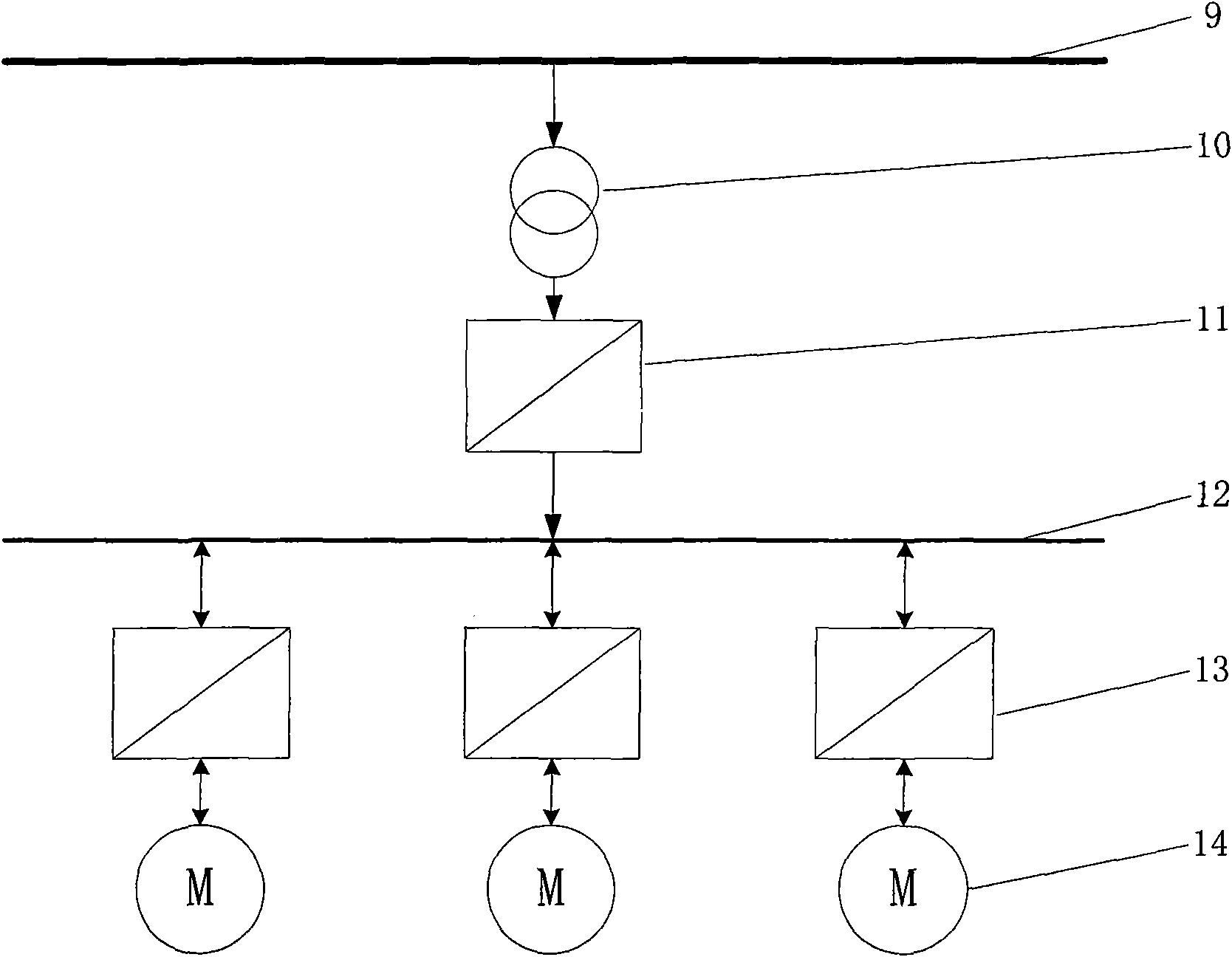

[0028] see figure 1 , which shows the working state of the electric closed tracked vehicle transmission steering test bench. As shown in the figure, (8) in the figure is the driving motor, and the driving motor is connected to the input end of the speed torque sensor (7) through the connection plate, and the output end of the speed torque sensor (7) is also connected to the tested object through the connection plate. connected to the input end of the piece (5); the output end of one side of the tested piece (5) is connected to the input end of the speed torque sensor (4) through the connection plate, and the output end of the speed torque sensor (4) is connected to the inertial The input end of the loading system (3) is connected; the output end of the inertial loading system (3) is connected to the multi-speed transmission box through the connecting plate

[0029] The input end of (2) is connected, and the output end of the multi-speed transmission box (2) is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com