Six-axis linked numerical control polishing machine

A six-axis linkage and polishing machine technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding drive devices, etc., can solve the problems of easy safety accidents, low production efficiency, and high labor intensity to ensure Polishing quality, improving production efficiency and benefit, quality has consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a further detailed description of the six-axis linkage CNC polishing machine of the present invention in conjunction with the accompanying drawings;

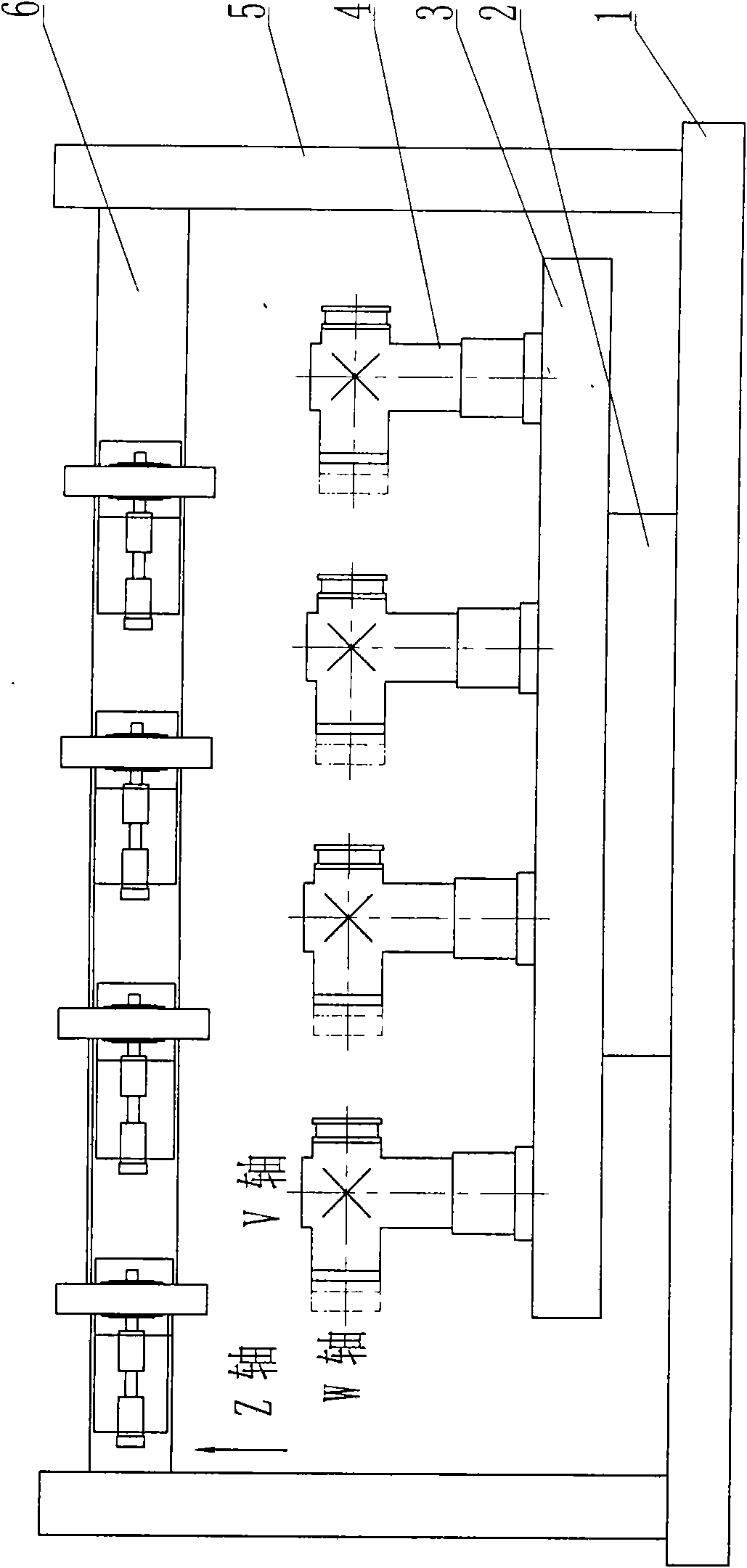

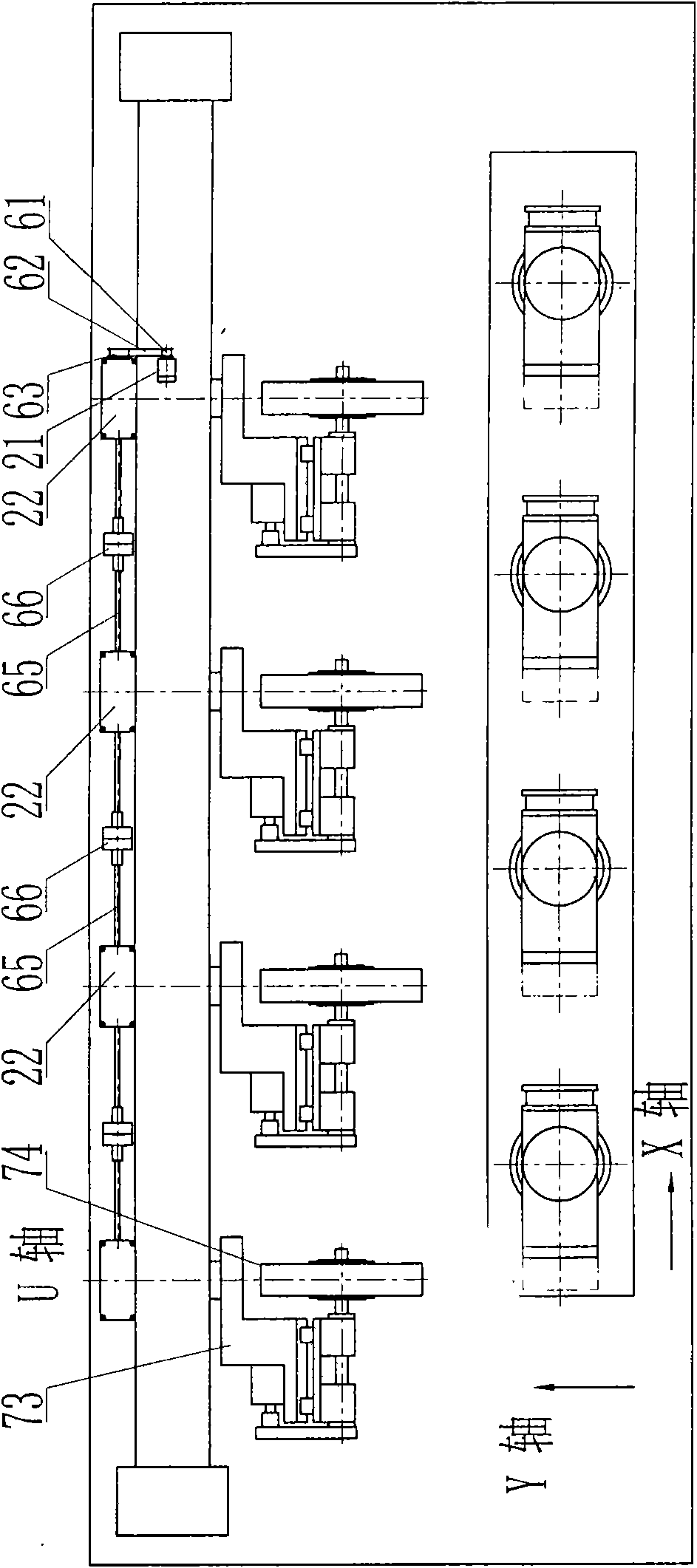

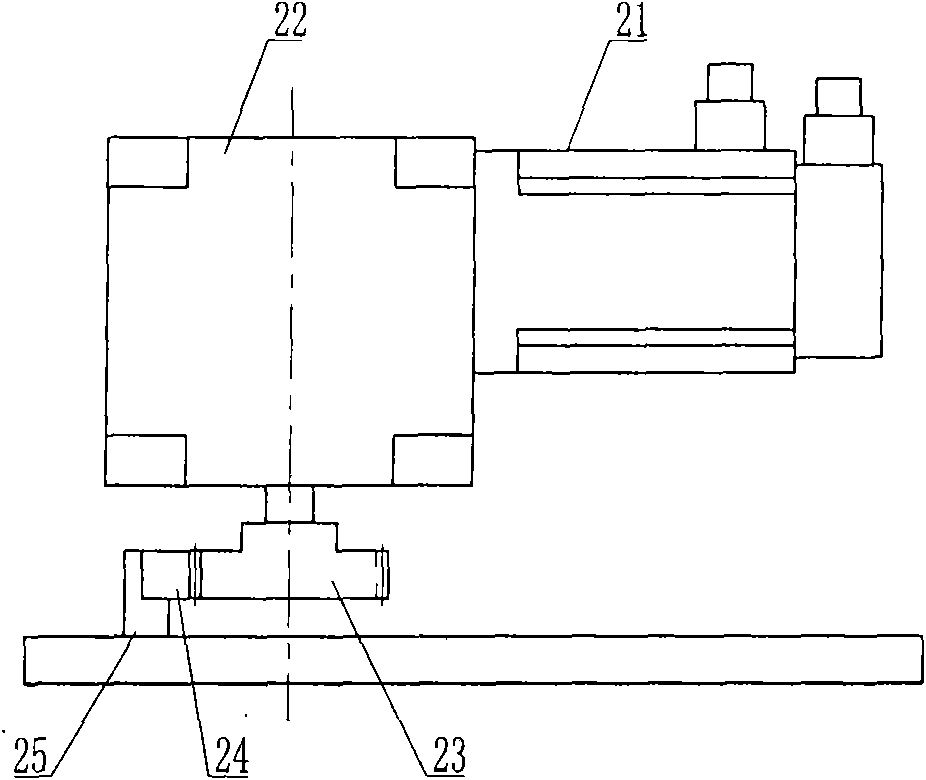

[0024] Such as figure 1 , figure 2 The six-axis linkage numerical control polishing machine of the present invention mainly consists of a large base 1, a movable base 2, a workbench 3, a tee swivel seat 4, a left and right column 5, a beam 6, a head frame 73, a polishing wheel 74 and the like. The movable base 2 moves linearly along the X-axis on the large base 1; the worktable 3 moves linearly along the Y-axis on the movable base 2; the three-way rotary seat 4 rotates around the V-axis on the worktable 3; Rotate around the W axis on the slewing seat 4; the beam 6 moves linearly along the Z axis on the column 5; the head frame 73 drives the polishing wheel 74 to rotate around the U axis, and all the above six movements are driven by servo motors independent of each other , linear motion via synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com