Water accumulating quenched-coke receiving slot

A water-logging, coke quenching technology, applied in coke ovens, coke cooling, petroleum industry, etc., can solve problems such as poor water content of coke, inability to spray water accumulation, long coke quenching time, etc., to achieve coke quenching time Short, guaranteed effective hardness, and the effect of controlling water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

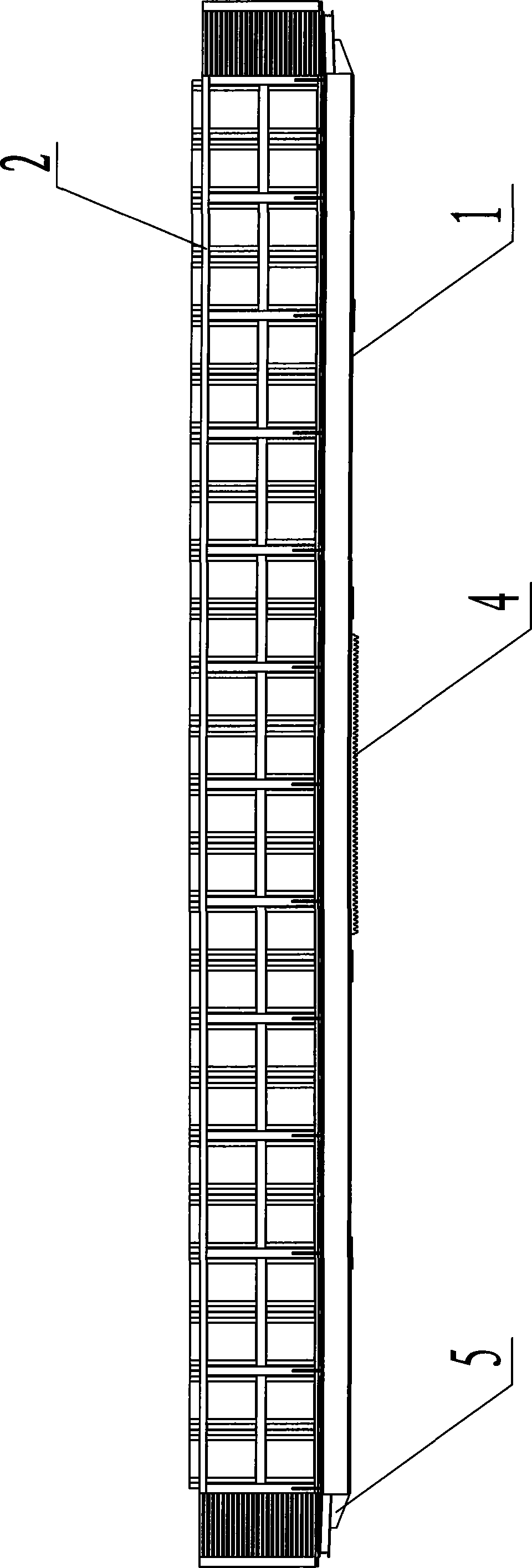

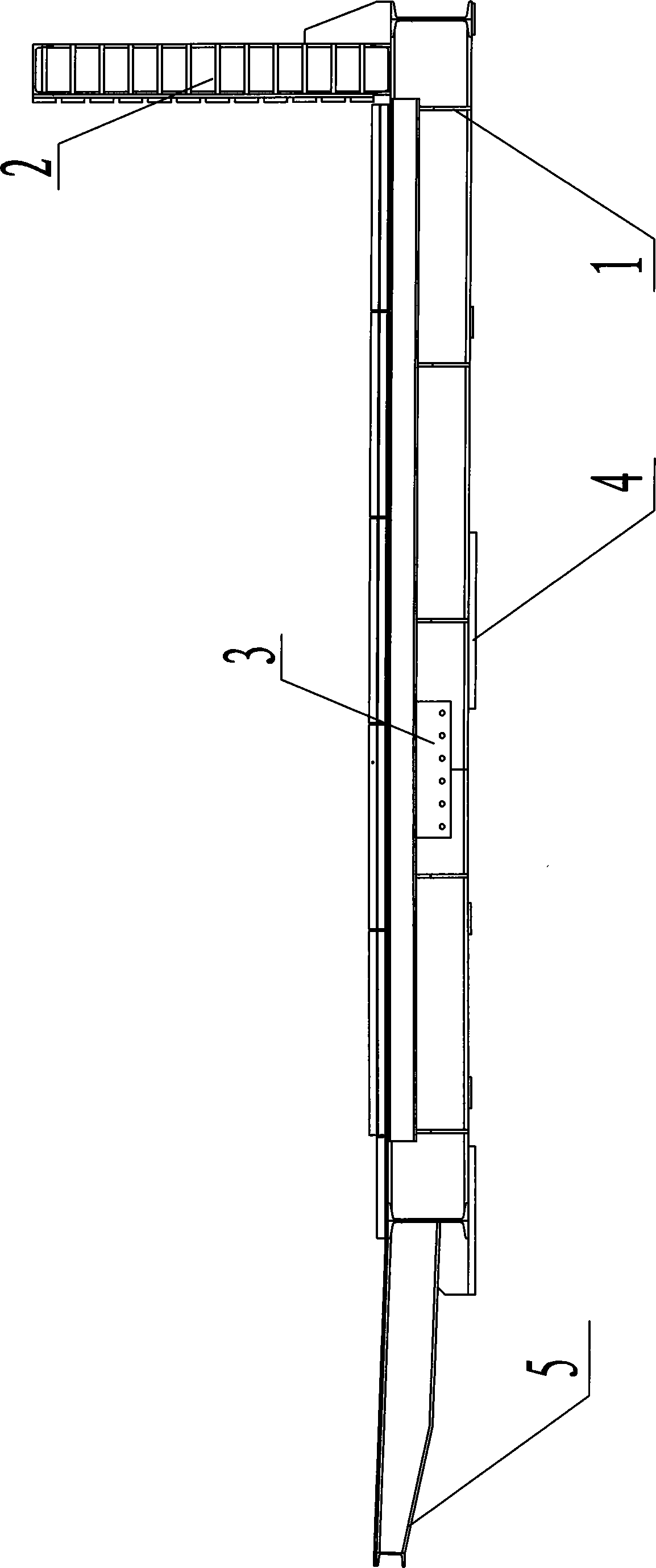

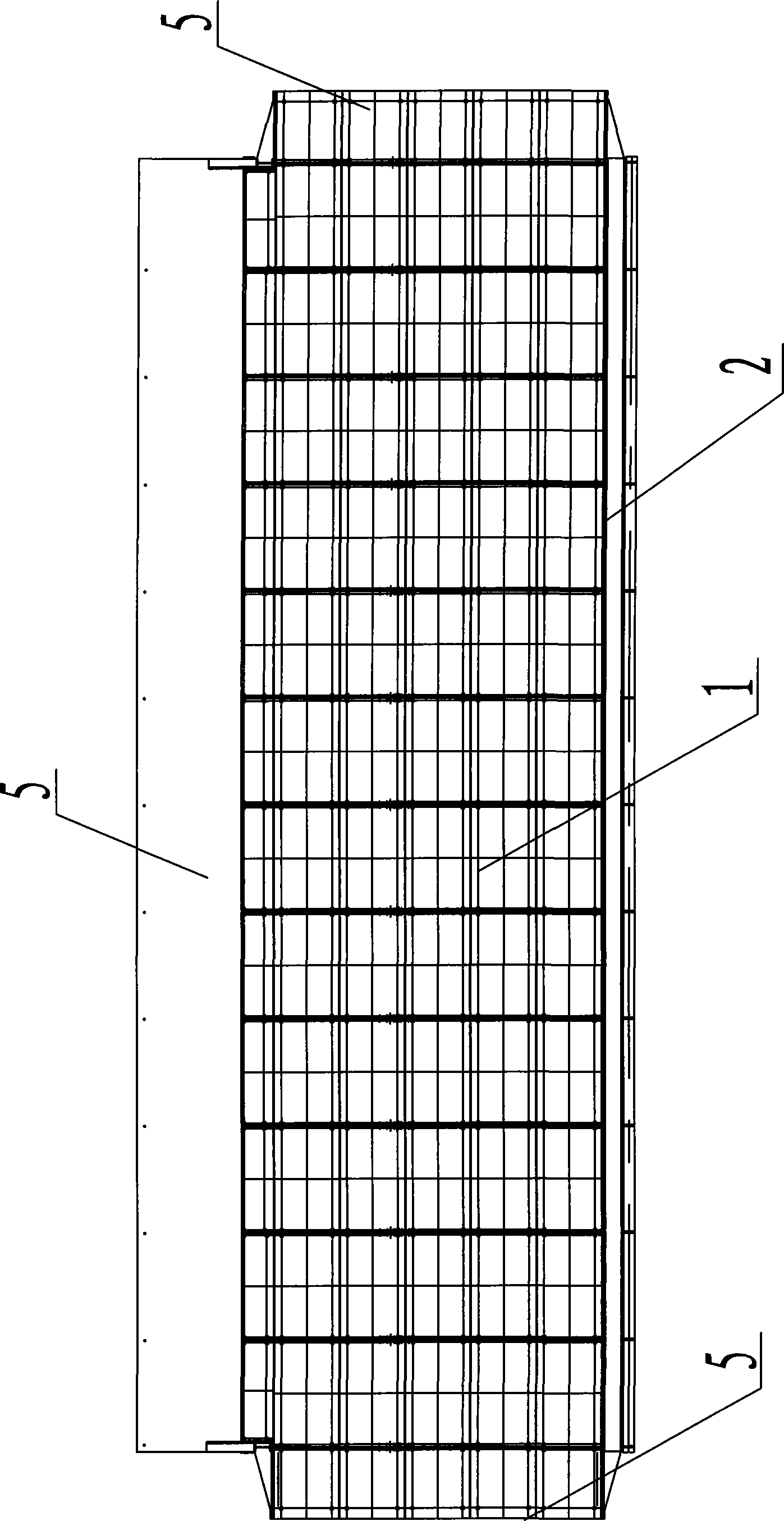

[0012] Such as figure 1 , figure 2 As shown, the coke quenching tank device of the ponding type includes: a steel structure bottom plate 1, a fixed side plate 2 is fixedly arranged on the upper end side of the steel structure bottom plate 1, and a heat-resistant plate 3 is arranged inside the steel structure bottom plate 1, A transmission rack 4 is arranged at the bottom of the steel structure bottom plate 1 . Such as image 3 As shown, on the other three sides of the steel structure bottom plate 1 are respectively provided with upturned ends 5, and the uplifted heights of the three uplifted ends 5 are 1.8-2.3 cm.

[0013] When the water-accumulating type connected to the coke quenching tank device with the above structure is in use, the steel structure bottom plate 1, the fixed side plate 2 and the three tilted en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com