Equipment used on spinning room preparation machines

A technology for preparing machines and equipment, which is applied to spinning machines, drafting equipment, and mechanical devices, etc. It can solve the problems of large space, disadvantages, and costs, and achieve the effects of simplifying adjustment procedures, saving space, and simplifying structure and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

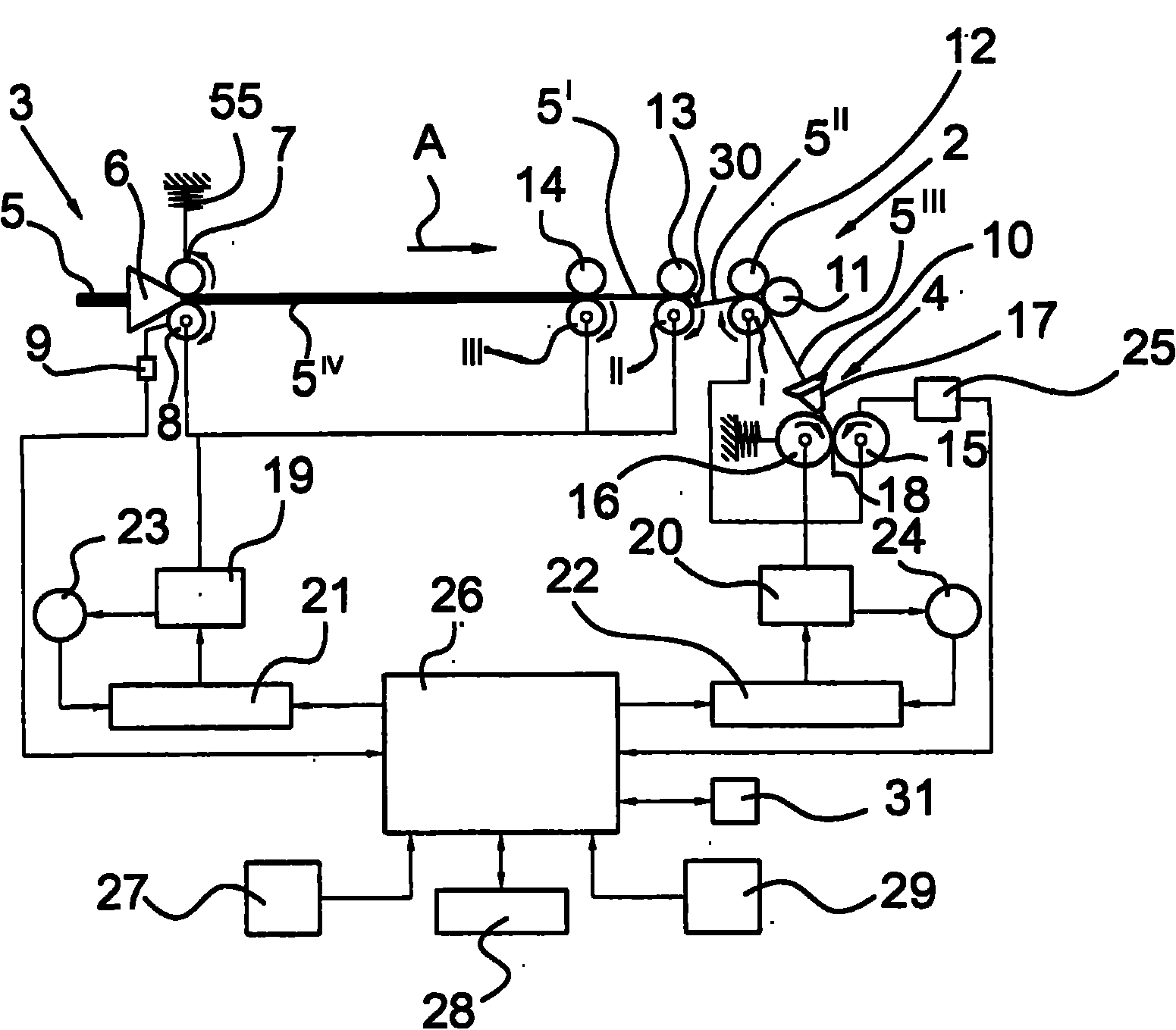

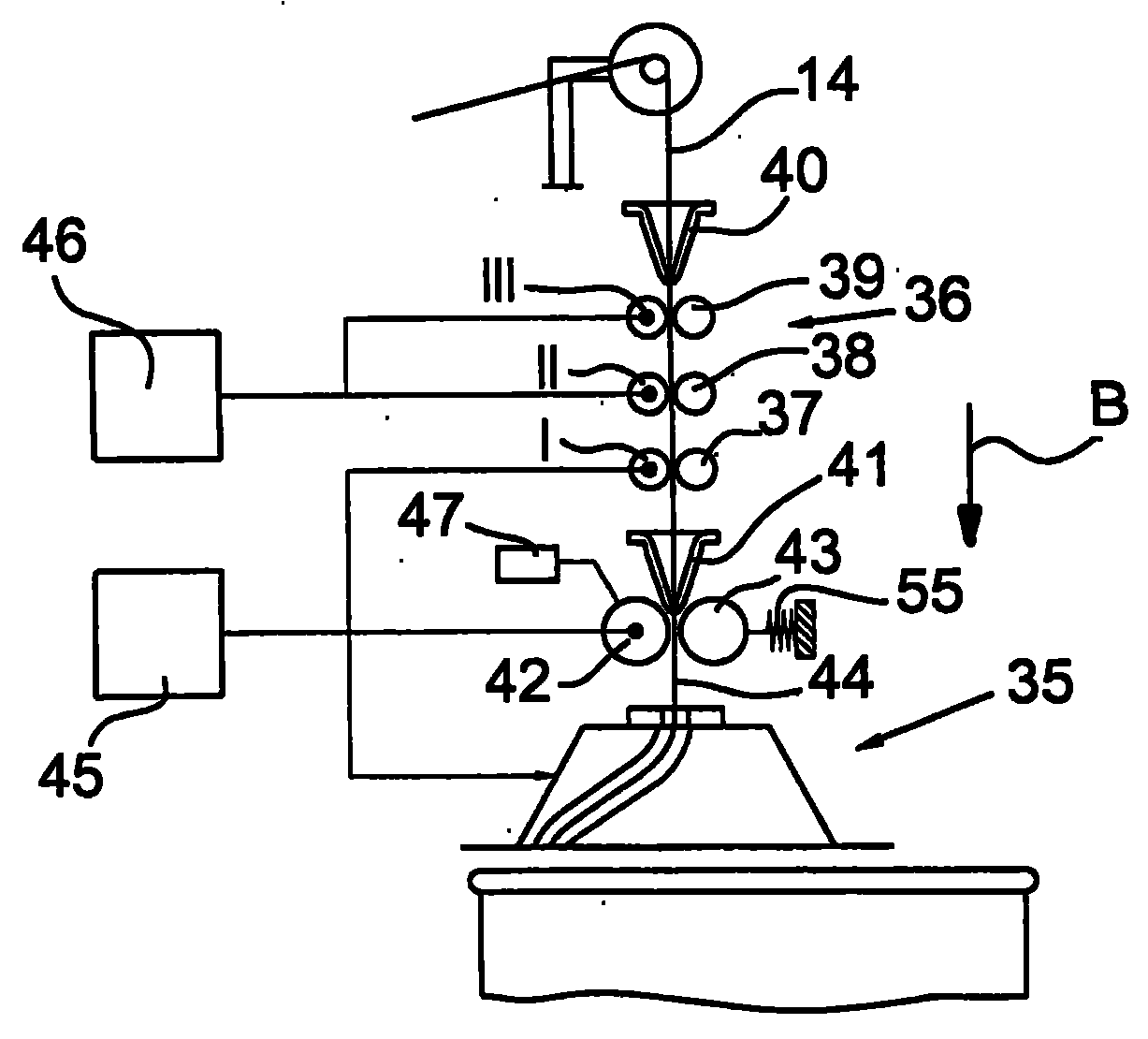

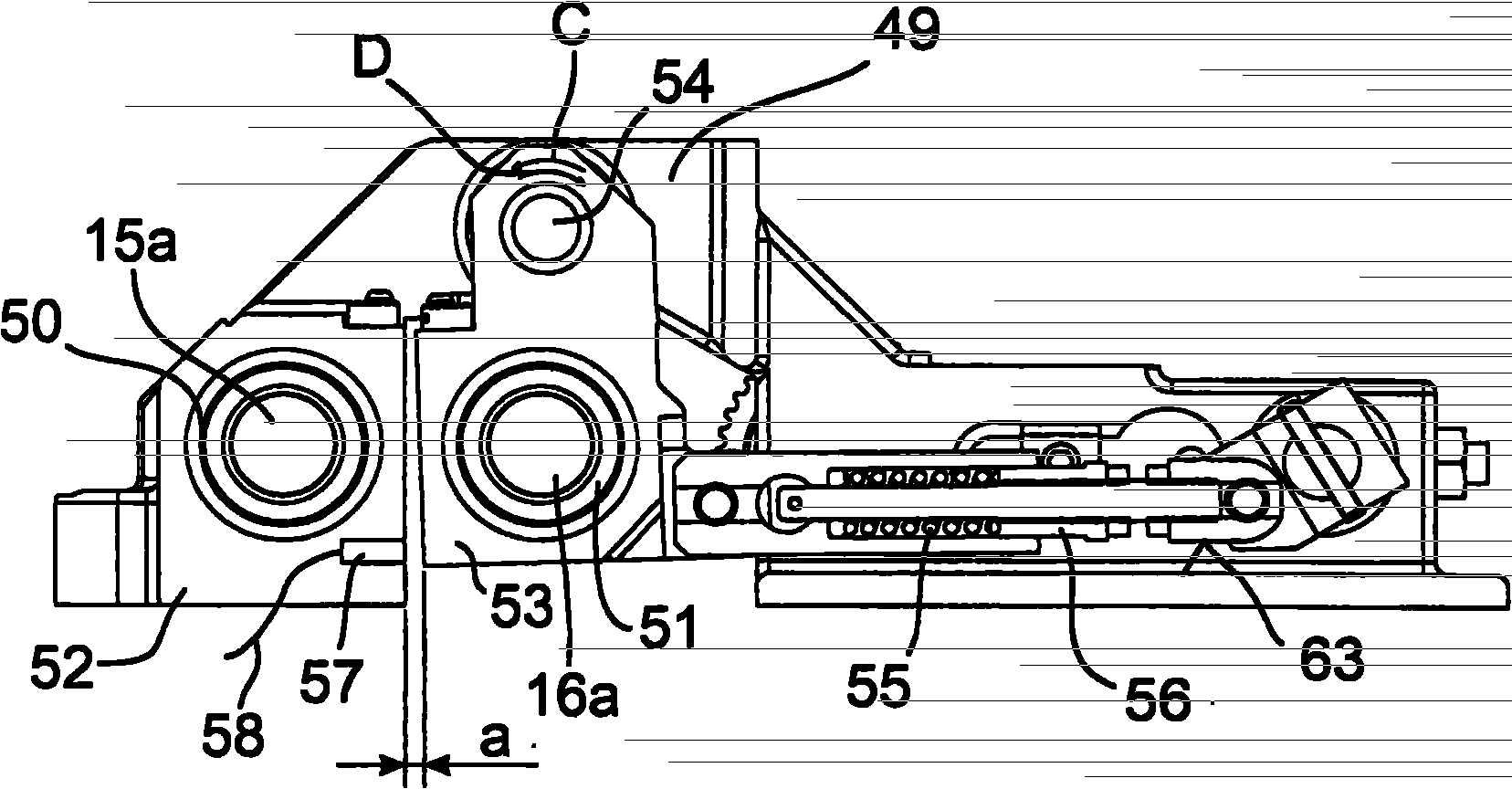

[0015] Such as figure 1 As shown, a draw frame 1 , for example of the Trützschler TD03 type, has a drafting mechanism 2 , upstream of which is an inlet 3 and downstream of which an outlet 4 . The sliver 5 from the can (not shown) enters the sliver guide 6 and is transported past the measuring element (distance sensor 9 ) drawn by the take-off rollers 7 , 8 . The drafting mechanism 2 is designed as a 4-up and 3-down drafting mechanism. That is, it includes three bottom rollers I, II, III (output bottom roller I, intermediate bottom roller II, input bottom roller III) and four top rollers 11, 12, 13, 14. Fiber strips are drawn from a plurality of fiber strips 5 and combined body 5 IV It is carried out in the drafting mechanism 2. The drafting process includes pre-drafting and main drafting. The roller pairs 14 / III and 13 / II form the pre-drafting zone and the roller pairs 13 / II and 11, 12 / I form the main drafting zone. Fiber strip merged body 5 I Drawing in the pre-drawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com